Production method of special network controlled-release fertilizer for eucalyptus

A special network and production method technology, applied in the application, fertilization device, fertilizer mixture, etc., can solve the problems of difficulty in accurately grasping the amount of fertilizer applied, difficulty in developing the fast growth of eucalyptus, labor and time-consuming top dressing, etc., to achieve less return and stable release , the effect of slow nutrient release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

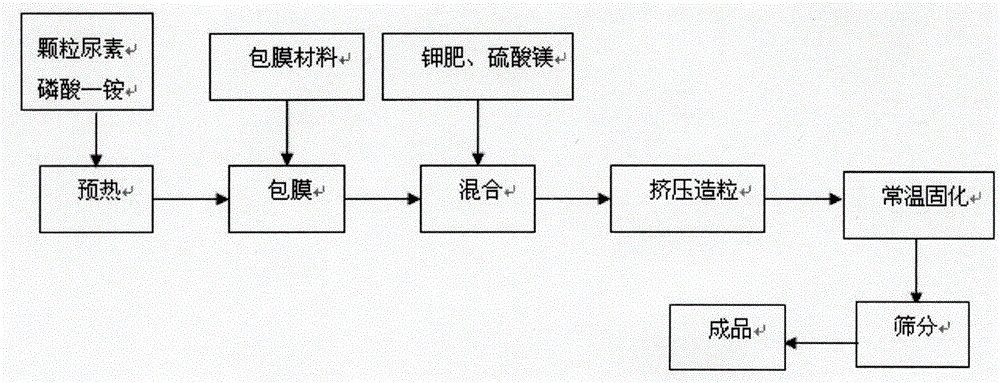

Method used

Image

Examples

example 1

[0022] Coating material configuration: nitrocellulose 7.10 kg, linseed oil modified aniline formaldehyde resin 1.50 kg, maleic anhydride rosin ester 2.50 kg, medium oil castor oil alkyd resin 5.00 kg, dibutyl phthalate 2.50 kg, 31.40 kg of mixed solvents were mixed evenly for later use; the mixed solvent formula was: 1.40 kg of alcohol, 2.80 kg of butanol, 5.25 kg of ethyl acetate, 8.75 kg of butyl acetate, and 13.20 kg of toluene.

[0023] First, 100 kg of granular urea (containing 46% nitrogen) and 500 kg of monoammonium phosphate (containing 11% nitrogen, containing 44% phosphorus pentoxide) preheated to 75 degrees were added to the drum coating machine, and the above preparation 50 kg of good coating materials are evenly added to the material in the drum coating machine for coating. After coating, 300 kg of potassium chloride (potassium oxide content 50%) and 100 kg of magnesium sulfate were added in sequence, and after mixing evenly, the mixture was added to an extrusion ...

example 2

[0025] Coating material configuration: nitrocellulose 14.00 kg, linseed oil modified aniline formaldehyde resin 2.80 kg, maleic anhydride rosin ester 2.10 kg, medium oil castor oil alkyd resin 7.00 kg, dibutyl phthalate 4.90 kg, 39.20 kg of mixed solvents were mixed evenly for later use; the mixed solvent formula was: 1.57 kg of alcohol, 3.14 kg of butanol, 5.25 kg of ethyl acetate, 7.80 kg of butyl acetate, and 21.44 kg of toluene.

[0026] First, 150 kg of granular urea (containing 46% nitrogen) and 450 kg of monoammonium phosphate (containing 11% nitrogen, containing 44% phosphorus pentoxide) preheated to 65 degrees were added to the drum coating machine, and the above preparation 70 kg of good coating material is evenly added to the material in the drum coating machine for coating. After the coating is completed, 380 kg of potassium sulfate (potassium oxide content 50%) and 150 kg of magnesium sulfate are added in sequence. After mixing evenly, the mixture is added to an e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com