Multi-cycle rapid thermal annealing method of amorphous silicon film

An amorphous silicon thin film, thermal annealing technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of expensive equipment, poor process repeatability, easy access of metals, etc., to reduce annealing time, The effect of uniform temperature distribution and increased annealing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

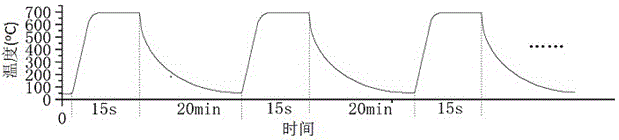

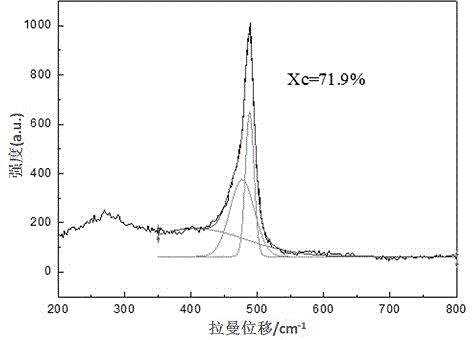

[0022] The process and steps in the embodiment of the present invention are as follows:

[0023] (1) Use an ordinary glass slide as a substrate, cut into small pieces with a size of 1cm×1cm, clean the surface of the sample with analytical pure acetone, ethanol and deionized water respectively, and blow dry with nitrogen.

[0024] (2) Put the cleaned glass substrate into the film deposition chamber, and use plasma enhanced chemical deposition (PECVD) equipment to deposit a layer of amorphous silicon (a-Si) film on the glass substrate with a thickness of about 200nm. The substrate temperature during deposition was 200 o C, the deposition pressure is 10 -5 Pa, the gas glow pressure range is 50Pa-250Pa, the sputtering power is 200W, the RF frequency is 13.56MHz, and the gas source is 100% pure silane (SiH 4 ), hydrogen used as dilute silane (H 2 ) with a purity of 5N.

[0025] (3) Use hydrofluoric acid to remove the oxide layer on the surface of the amorphous silicon film. Pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com