Surface-aminated Fe3O4 nano particle and preparation method and application thereof

A technology of surface amination and nano-particles, applied in chemical instruments and methods, inorganic chemistry, ion exchange, etc., can solve the problems of long reaction time, poor particle shape and complicated preparation process of coprecipitation method, and shorten the time Effects of processing time, improving efficiency, and simplifying steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1, aminated magnetic Fe 3 o 4 Synthesis of Nanoparticles

[0045] (1) Magnetic Fe 3 o 4 Synthesis of Nanoparticles

[0046] Pass nitrogen gas into a 500mL Erlenmeyer flask for about 20min, then add 2gFeCl to it in sequence 2 4H 2 O, 5.2 g FeCl 3 ·6H 2 O. Dissolve 0.85mL of 12mol / L hydrochloric acid in 200mL of water, and ultrasonically deoxygenate for 20min. Prepare 250mL of 0.75mol / L sodium hydroxide solution and ultrasonically deoxygenate for 20min. Add the prepared hydrochloric acid solution and sodium hydroxide solution to the Erlenmeyer flask in turn, put in the magnet, and pass nitrogen gas again for about 10 minutes to ensure that the Erlenmeyer flask is filled with nitrogen, and quickly cover the Erlenmeyer flask with the cap and seal it. In the environment of the water bath of 80 ℃, electromagnetic stirring was reacted for 2h, and black precipitate was obtained. Separated with an external magnetic field, washed 3 times with deionized water...

Embodiment 2

[0050] Embodiment 2, aminated magnetic Fe 3 o 4 Synthesis of Nanoparticles

[0051] (1) Take about 0.7g of 2mmol of iron (III) acetylacetonate, about 2.6g of 10mmol of 1,2-hexadecane diol, about 20mL of diphenyl ether or dibenzyl ether, about 2.6ml of 6mmol of oleyl ammonia , 6mmol of oleic acid, about 2.6mL, was put into a three-neck flask. In order to prevent the oxidation of the medicine, nitrogen gas should be passed for 20 minutes before adding the medicine. Under the condition of nitrogen protection, be heated to 200 ℃ with the speed of 10 ℃ per minute, react 1h, be heated to 260 ℃ again, react 30min. Stop heating, let it return to room temperature, add 40 mL of ethanol to the reaction solution, and centrifuge at a speed of 10000 r / min for 20 min in a centrifuge to obtain a black precipitate. Discard the supernatant, and wash the black precipitate with absolute ethanol 2-3 times to obtain magnetic Fe 3 o 4 Nanoparticles. will get Fe 3 o 4 The nanoparticles are di...

Embodiment 3

[0054] Embodiment 3, aminated magnetic Fe 3 o 4 Performance testing of nanoparticles

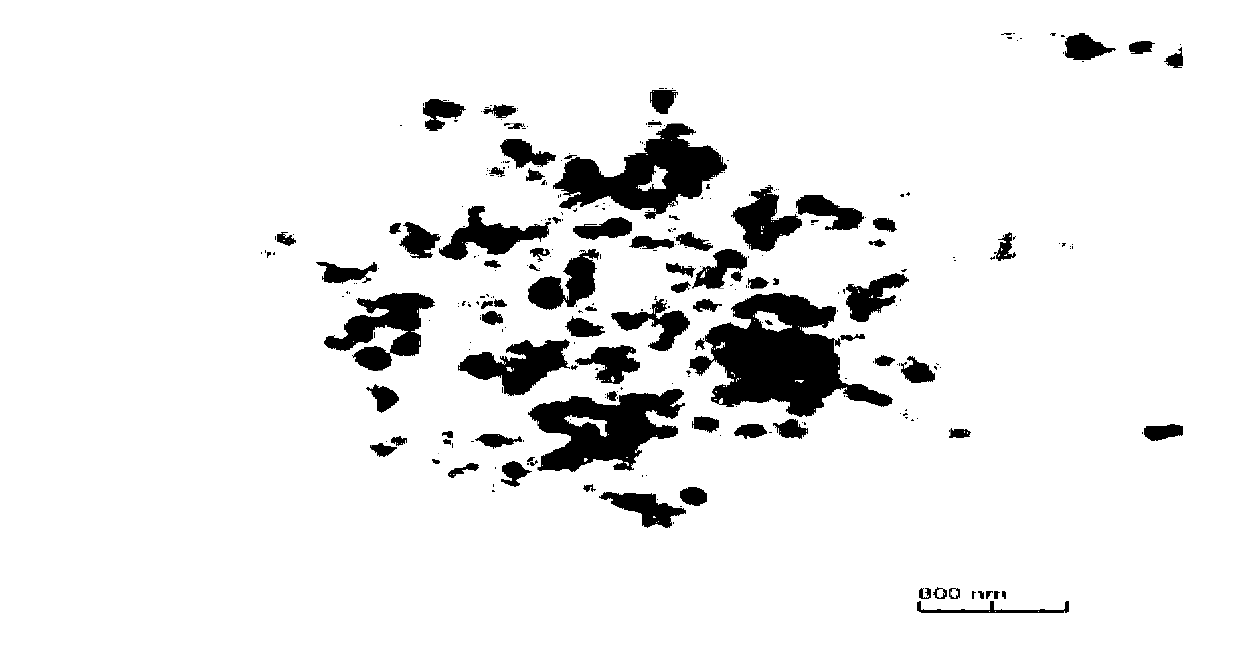

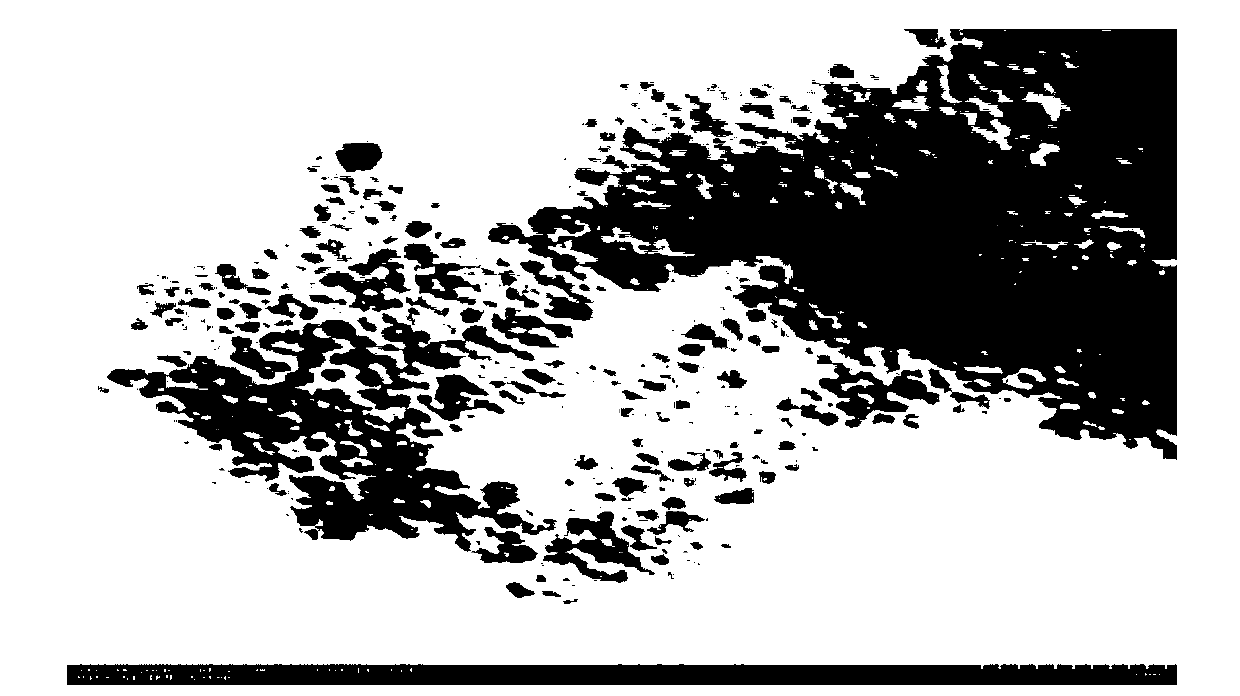

[0055] (1) TEM analysis

[0056] In order to determine the size of the prepared particles and overcome the agglomeration of the solid sample during electron microscope detection, the prepared magnetic Fe 3 o 4 Nanoparticles and their magnetic Fe after amination 3 o 4 The nanoparticles are fully dispersed with n-hexane, the sample is dropped on the copper grid, and the scanning detection of the transmission electron microscope is carried out. The transmission electron microscope image (TEM) is as follows: figure 1 shown. As can be seen from the picture, the magnetic Fe synthesized in the organic phase (Example 2) 3 o 4 Nanoparticles present obvious regular hexahedral shape, particle size is consistent, all about 50nm, neatly arranged, showing the arrangement rule of superlattice. Inorganic Phase Synthesis (Example 1) of Magnetic Fe 3 o 4 Compared with the particles synthesized in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com