Lactase and recombinant expression engineering bacterium thereof

A technology of lactase and engineering bacteria, applied in genetic engineering, enzymes, fungi, etc., can solve the problems of low expression level and difficult expression level of lactase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Cloning of embodiment 1 Aspergillus oryzae lactase gene

[0054] 1. Extraction of total genome DNA of Aspergillus oryzae

[0055] Aspergillus oryzae mycelium was filtered with sterile filter paper and placed in a mortar, 2 mL of extract was added, and ground for 5 min, then the grinding liquid was placed in a 50 mL centrifuge tube, lysed in a water bath at 65°C for 20 min, mixed every 10 min, and Centrifuge at 10,000rpm at 4°C for 10min, extract the supernatant with phenol / chloroform to remove impurities, add an equal volume of isopropanol to the supernatant, let stand at room temperature for 5min, centrifuge at 10,000rpm at 4°C for 10min, discard the supernatant, and use 70 Wash with % ethanol twice, dry in vacuum, dissolve in appropriate amount of water, store at -20°C for later use

[0057] Using the extracted total DNA as a template, PCR amplification was performed using primers P1 / P2.

[0058] P1: CGGGGTACCATGAAGCTCCCTCTCTGTTGCTGCTG-----...

Embodiment 2

[0061] Example 2 Construction of expression vector

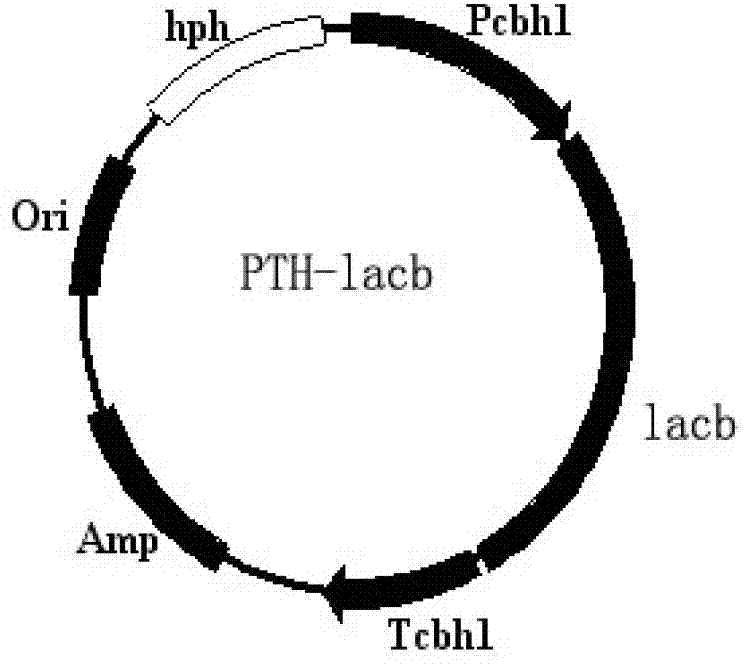

[0062] Extract the plasmid pMDlac-19T (refer to the instructions of the plasmid mini-extraction kit from OMIGA Reagent Company for specific steps), then digest the pMDlac-19T plasmid with KpnI and XbaI, and recover the lacb lactase gene fragment by gel. At the same time, the Trichoderma expression plasmid pTH vector was also recovered by KpnI and XbaI double-enzyme digestion gels. The cloned gene (lacb) and expression vector (PTH) were ligated overnight at 22°C with T4 ligase. Finally, the ligated product was introduced into E. coli DH5α. Transformant PCR verification, the amplification conditions are: 94°C for 4min, 94°C for 1min, 63°C for 30s, 72°C for 3.5min, a total of 30 cycles, and finally 72°C for 10min, the positive clone is the recombinant vector pTH- lacb, a plasmid map such as figure 1 shown.

Embodiment 3

[0063] Example 3 Protoplast Transformation

[0064] 1. Bacteria culture

[0065] Carefully cover a layer of cellophane on the PDA plate, spread it flat with a glass rod, apply 100-200u activated spore suspension on the cellophane, spread evenly, and incubate at 30°C for about 16h.

[0066] 2. Protoplast preparation

[0067] Inoculate Trichoderma reesei hyphae and grow on PDA plates for 4 days; cut colonies with a diameter of about 3 cm and place them in about 60 ml of YEG (0.5% yeast powder, 1% glucose) liquid medium, shake at 30°C and 200 rpm overnight; Collect the mycelia by filtering with multi-layer gauze; place the mycelium in 10-20 ml of lysing enzyme solution (Sigma L1412) for 2-3 hours; take out the enzymatic solution, add 0.7 M NaCl solution, shake gently, and pour it into Filter with three layers of sterile lens tissue, collect the filtrate, centrifuge at 3000 rpm for 10 min; discard the supernatant, add 10-20 ml of STC solution (20% sucrose, 50mM Tris-Cl, 50mM CaC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com