Preparation method of titanium dioxide coated iron trioxide hollow sphere

A technology of ferric oxide and titanium dioxide, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of low photon efficiency, short hole life, narrow hole Bandwidth and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

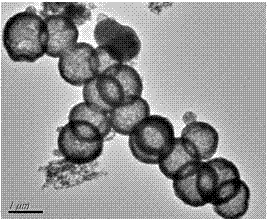

[0018] Dissolve 6 g of glucose in 40 mL of deionized water to form a solution with a mass concentration of 0.15 g / mL, transfer the solution into a reaction kettle for hydrothermal reaction at a temperature of 180 °C, and a reaction time of 6 h, then centrifuge and dry to obtain Carbon sphere template; Dissolve 0.82 g of ferric chloride in a mixed solution of 56 mL of absolute ethanol and deionized water, wherein the volume ratio of absolute ethanol and deionized water is 6: 1, and dissolve 1.8 g of urea in the above solution , stirred until dissolved, added 0.3 g carbon sphere template to the above solution, mixed evenly, transferred to an oven at 60°C for 48 hours, and was centrifuged and dried. The resulting sample was calcined at 450 °C for 2 hours to remove the carbon sphere template and obtain Fe 2 o 3 Hollow sphere, to present embodiment product (Fe 2 o 3 Hollow sphere) to observe its microscopic morphology by transmission electron microscopy, the results are as follo...

Embodiment 2

[0020] Dissolve 8 g of glucose in 40 mL of deionized water to form a solution with a mass concentration of 0.2 g / mL, transfer the solution into a reactor for hydrothermal reaction at a temperature of 160 °C, and a reaction time of 8 h, then centrifuge and dry to obtain Carbon sphere template; Dissolve 0.82 g of ferric chloride in a mixed solution of 56 mL of absolute ethanol and deionized water, wherein the volume ratio of absolute ethanol and deionized water is 6: 1, and dissolve 1.8 g of urea in the above solution , stirred until dissolved, added 0.3 g carbon sphere template to the above solution, mixed evenly, transferred to an oven at 60°C for 48 hours, and centrifuged to dry. The obtained sample was calcined at 500°C for 2 hours to remove the carbon sphere template to obtain Fe 2 o 3 Hollow sphere, size and structure are similar to the results obtained in Example 1.

Embodiment 3

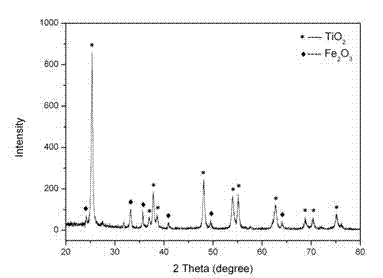

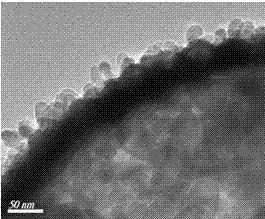

[0022] 0.48 g of the sample prepared in Example 1 without heat treatment was dispersed in a mixed solution of 56 mL of absolute ethanol and deionized water, wherein the volume ratio of absolute ethanol and deionized water was 6: 1; 0.35 mL Tetrabutyl titanate was added to the above solution, so that the molar ratio of titanium ions to iron ions was 1: 2, stirred evenly, the solution was kept in an oven at 60°C for 48 hours, and dried by centrifugation, and the obtained sample was roasted at 450°C for 2 Hours, obtained titanium dioxide-coated ferric oxide hollow spheres, the product of this example (titanium dioxide-coated ferric oxide hollow spheres) X-ray powder diffraction results are as follows figure 2 As shown, the mark * in the figure is the characteristic peak of titanium dioxide, and ? is the characteristic peak of ferric oxide, and the prepared samples simultaneously appear Fe 2 o 3 and TiO 2 The characteristic peak, and consistent with the standard PDF card, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com