Preparation method of spherical high-voltage lithium nickel manganate anode material

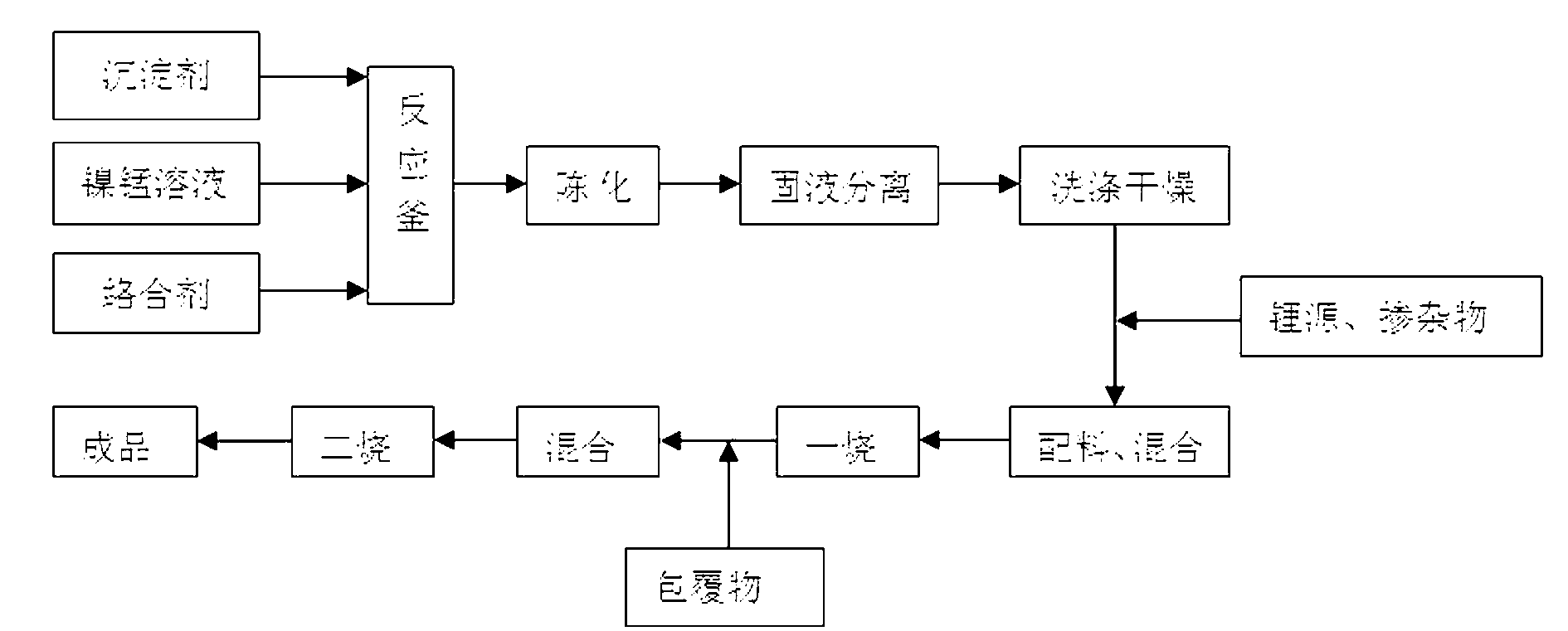

A technology of lithium nickel manganate and cathode material, which is applied in the field of preparation of spherical high-voltage cathode materials for lithium ion batteries, can solve the problems of impure product phase, complicated process, incomplete mixing, etc., and achieves simplified production process flow, The element ratio is uniform and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

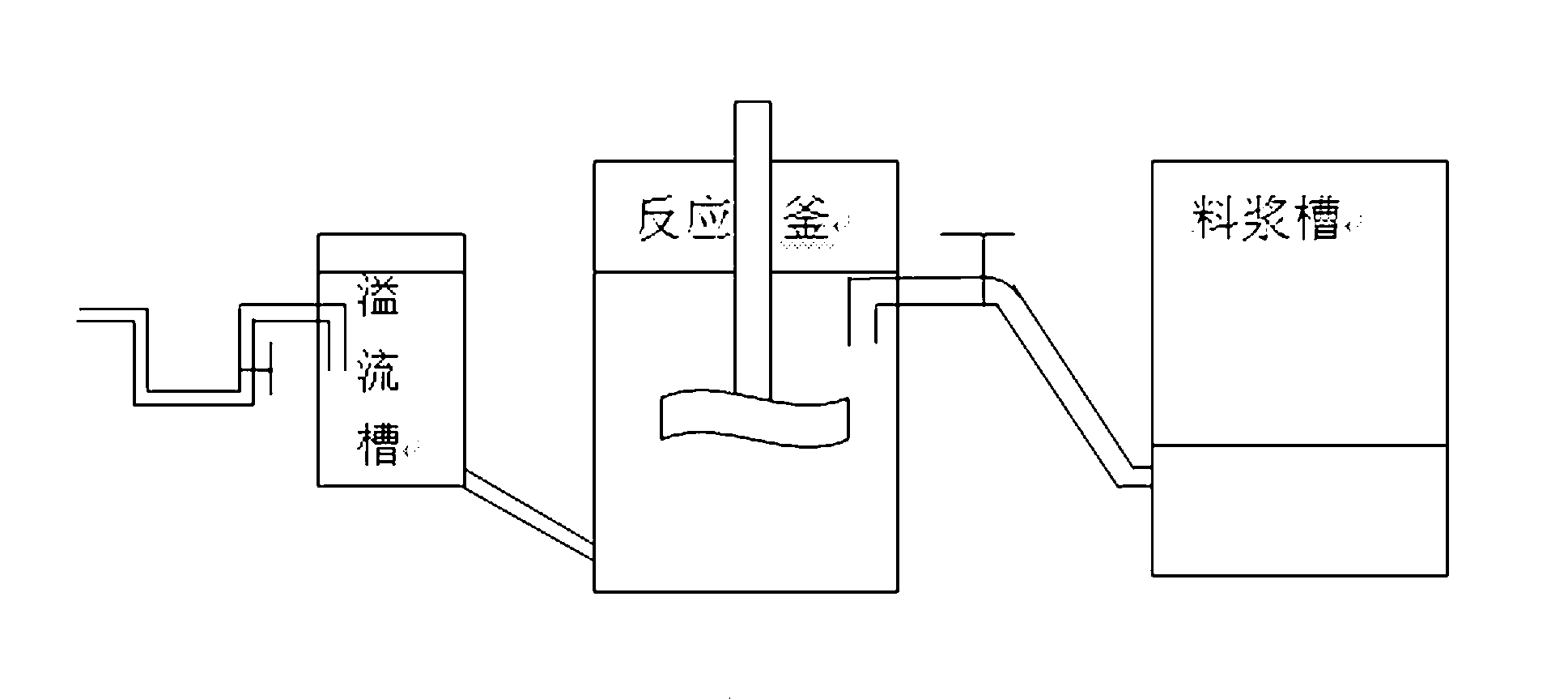

Method used

Image

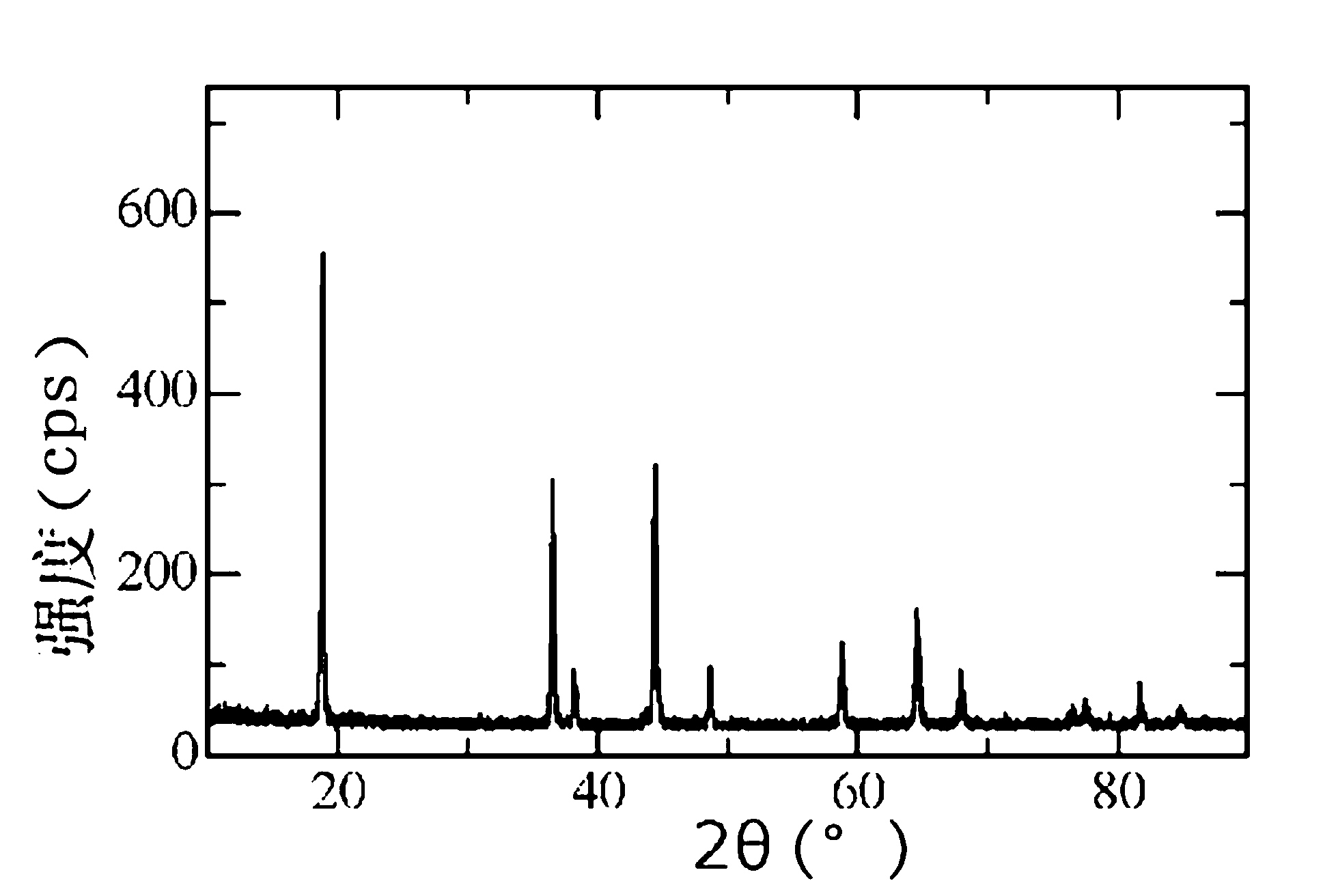

Examples

Embodiment 1

[0023] 1) According to the chemical formula [Li(Ni 0.5 mn 1.5 ) F 0.01o 3.99 ] 0.99 ·[ZnO] 0.01 The stoichiometry of the lithium source compound, nickel salt, manganese salt, Al source compound and coating agent ZnO was weighed, and a mixed solution with a molar ratio of nickel and manganese elements of 1:3 and a metal ion concentration of 120g / L was prepared with pure water. Preparation of manganese solution: nickel sulfate, manganese sulfate. Prepare 2mol / L sodium hydroxide solution with pure water. Prepare 1mol / L ammonia water with liquid ammonia, add antioxidant hydrazine hydrate to the ammonia water, and add concentration of 0.5L / m 3 .

[0024] Prepare the bottom solution containing ammonia water and hydrazine hydrate, the pH value is controlled at 9.5, the concentration of ammonia water is 13g / L, and the concentration of hydrazine hydrate is 0.5L / m 3 , the temperature is 55°C, the stirring speed is 120r / min, and the nickel-manganese solution, sodium hydroxide sol...

Embodiment 2

[0028] 1) According to the chemical formula [Li(Ni 0.45 mn 1.5 al 0.05 ) F 0.05 o 3.95 ] 0.98 ·[ZnO] 0.02 The stoichiometry of the lithium source compound, nickel salt, manganese salt, Al source compound and coating agent ZnO is weighed, and the nickel-manganese binary precursor is prepared with pure water. The molar ratio of the elements is 1:3.33, and the metal ion concentration is 200g / L. Mixed solution, nickel manganese solution preparation: nickel sulfate, manganese sulfate. Prepare 5mol / L sodium hydroxide solution with pure water. Prepare 4mol / L ammonia water with liquid ammonia, add antioxidant hydrazine hydrate to the ammonia water, and add concentration of 2.0L / m 3 .

[0029] Prepare the bottom liquid containing ammonia water and hydrazine hydrate, the pH value is controlled at 12.0, the concentration of ammonia water is 50g / L, and the concentration of hydrazine hydrate is 2.0L / m 3 , the temperature is 70°C, the stirring speed is 170r / min, feed the nickel-man...

Embodiment 3

[0033] According to the chemical formula [Li(Ni 0.42 mn 1.5 co 0.04 Zn 0.04 ) F 0.2 o 3.8 ] 0.97 [ZnO] 0.03 The stoichiometric ratio of lithium source compound, nickel salt, manganese salt, Co source compound, Zn source compound and coating agent ZnO is weighed, and the molar ratio of nickel to manganese is 1:3.5, and the metal ion concentration is 150g / L. Mixed solution, nickel manganese solution preparation with nickel nitrate, manganese nitrate. Prepare 3mol / L sodium hydroxide solution with pure water. Prepare 3mol / L ammonia water with liquid ammonia, add antioxidant hydrazine hydrate to the ammonia water, and add concentration of 2.0L / m 3 .

[0034] Prepare the bottom liquid containing ammonia water and hydrazine hydrate, the pH value is controlled at 10.25, the concentration of ammonia water is 17g / L, and the concentration of hydrazine hydrate is 1.0L / m 3 , the temperature is 58°C, the stirring speed is 150r / min, and the nickel-manganese solution, sodium hydroxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com