Preparation method of N-methyl diethanolamine

A technology of methyldiethanolamine and monomethylamine, which is applied in the preparation of organic compounds, preparation of aminohydroxyl compounds, chemical instruments and methods, etc. It can solve problems such as low vacuum degree, insufficient mixing of raw materials, excessive side reactions, etc. , to achieve the effect of reducing excessive consumption, reducing unit consumption of raw materials, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

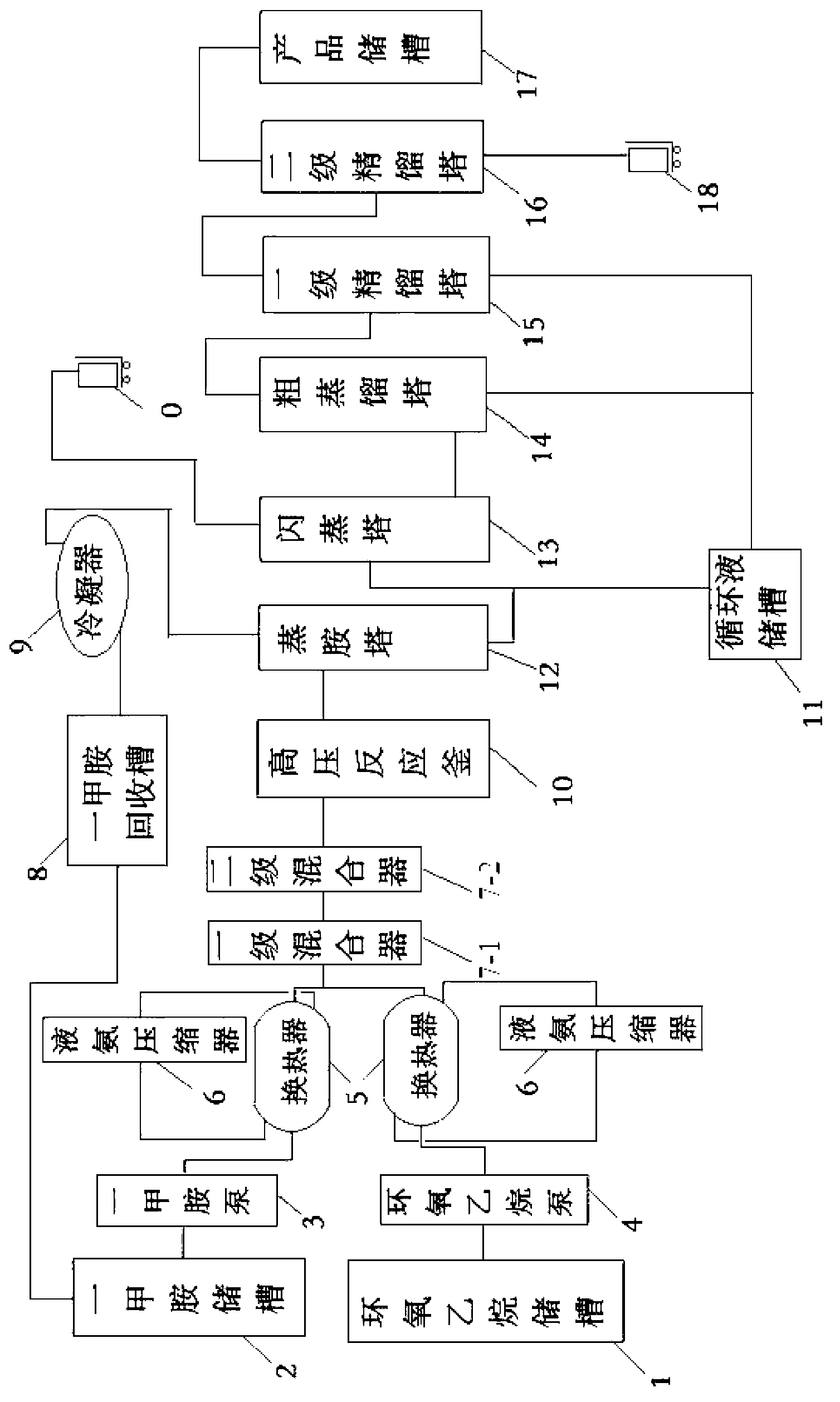

[0031] combine figure 1 The inventive method is described, figure 1 The scheme shown is a preferred embodiment of the process of the present invention.

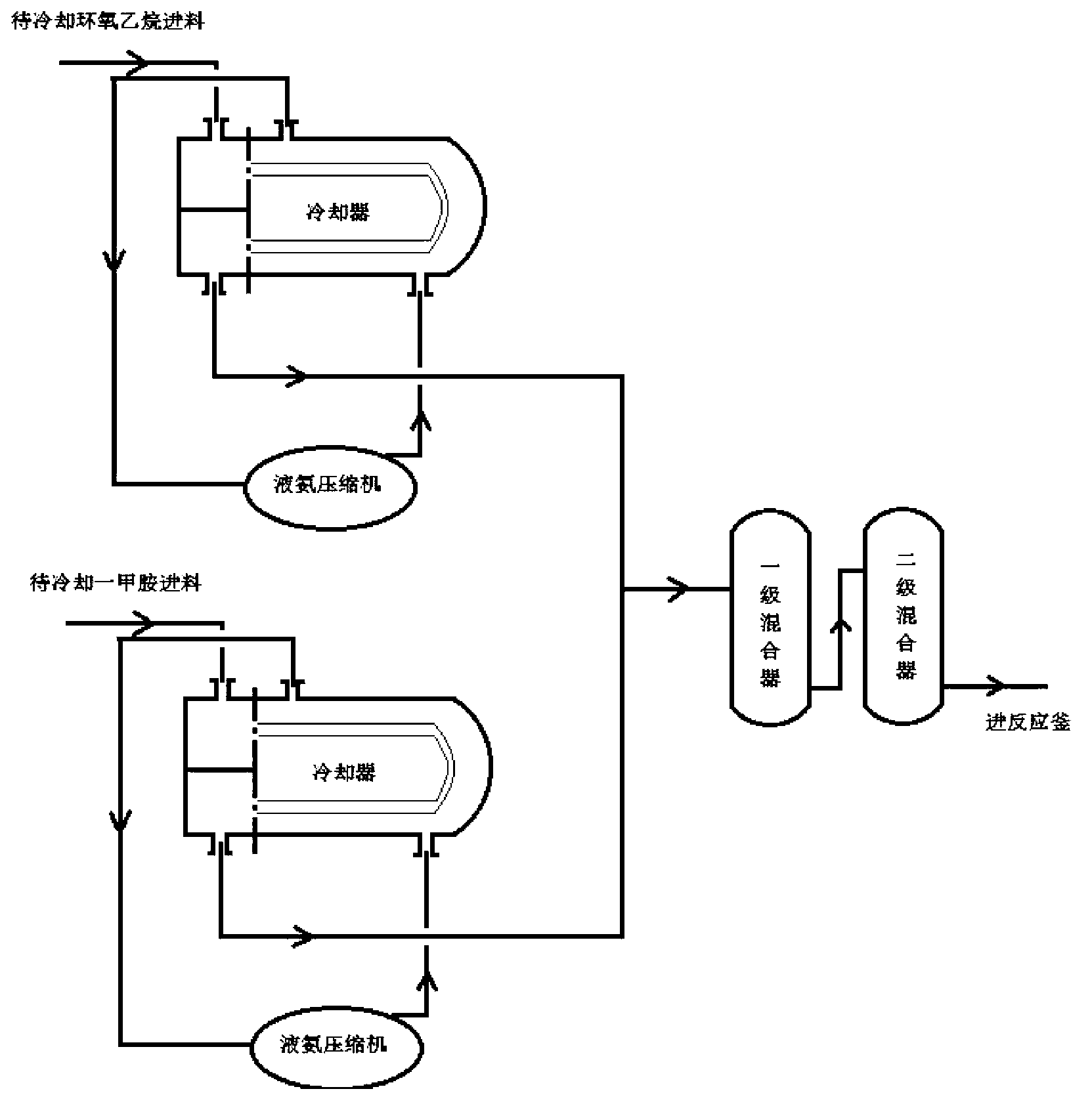

[0032] (1) The raw materials of ethylene oxide and monomethylamine are respectively passed through the metering pump ethylene oxide pump 4 and monomethylamine pump 3, and adjusted according to the material ratio of monomethylamine and ethylene oxide as 1.5:1 The flow rate is respectively introduced into two heat exchangers 5 for cooling. 5 is a U-shaped shell-and-tube heat exchanger, with a single shell and two tubes, and liquid ammonia is used for cooling. The pressure in the tube is 0.1~0.3MPa, the pressure in the tube is 0.4~0.5MPa, the raw material is cooled to 2°C, and the cooled raw material is passed into the primary mixer 7-1 and the secondary mixer 7-2 to fully mix. The pressure of the primary mixer and the secondary mixer is 0.4~0.5MPa to obtain mixed raw materials.

[0033] (2) Put the mixed raw materials into t...

Embodiment 2

[0044] Each technical condition is the same as embodiment 1, and difference is:

[0045] In step (5), the temperature at the top of the primary distillation column is 110°C, and the vacuum inside the column is -0.06MPa.

[0046] The top temperature of the secondary rectification tower is 88°C, and the vacuum degree in the tower is -0.95MPa.

[0047] The yield of the obtained N-methyldiethanolamine product is 90.4%, the selectivity is 94.1%, and the color purity of the product is very good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com