Organic solar battery and preparation method thereof

A solar cell, organic technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of expensive preparation, reduced device stability, substrate corrosion, etc., and achieves simple process, stable performance, and high conversion efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

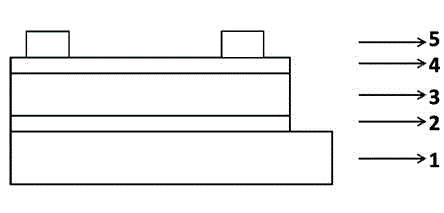

Image

Examples

preparation example Construction

[0041] 2 Preparation of hole transport layer CuS thin film

[0042] (1) Put the metal copper target and the clean conductive glass substrate into the corresponding positions in the deposition chamber, adjust the position of the sample holder to align with the target surface and keep an appropriate distance.

[0043] (2) Vacuum the vacuum system. Turn on the cooling water first. Turn on the mechanical pump to draw a low vacuum. When the vacuum degree of the system is lower than 10Pa, turn on the molecular pump to draw a high vacuum until the system vacuum degree is better than 1×10 -3 Pa.

[0044] (3) Feed an appropriate amount of high-purity argon into the deposition chamber to make the argon pressure reach the required deposition pressure.

[0045] (4) Adopt general radio frequency planar magnetron sputtering process. High-purity argon is used as the sputtering and reaction gas, without oxygen in the whole process 。During sputtering, the contrast temperature was chang...

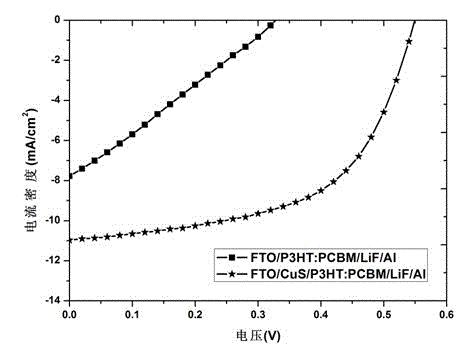

Embodiment 1

[0056] (1) Clean the FTO conductive glass: first put the conductive glass slide into a solution containing a detergent (such as Liby brand liquid detergent) and soak for 10 minutes, then scrub it repeatedly and rinse it with clean water; then use polishing powder to clean it. Polishing treatment; then put them into containers containing deionized water, acetone and alcohol and ultrasonically for 10 minutes respectively; finally put them into deionized water to rinse twice, blow dry with a nitrogen gun and put them in an oven at 80 degrees Celsius to eliminate stress.

[0057] (2) Formulation of the organic photosensitive layer: Weigh 20.0 mg of P3HT and 20.0 mg of PCBM with an electronic balance. After mixing, dissolve it in 1.0 mL of chlorobenzene. Then put it on a temperature-controlled magnetic stirrer and stir at 40°C for 24 hours.

[0058] (3) In an inert gas-protected gas box, a layer of P3HT:PCBM with a thickness of about 100 nm was thrown on the FTO substrate by the ...

Embodiment 2

[0063] (1) Clean the FTO conductive glass sheet, the same as in Example 1.

[0064] (2) Sputtering Cu thin film: Put the copper target and substrate into the magnetron sputtering equipment, and sputter with radio frequency power supply. The working conditions are: background vacuum: 3×10 -4 Pa; argon gas flow rate of 12 sccm (standard condition milliliters per minute); substrate temperature: 60°C, sputtering pressure: 1.0 Pa, sputtering power at 60W, and sputtering time of 5 s. The FTO glass substrate coated with Cu film was obtained.

[0065] (3) Preparation of CuS thin film: Put Cu-coated FTO glass into a 100ml polytetrafluoroethylene autoclave, add 0.03g of sulfur powder and 70ml of absolute ethanol successively. Place the reaction kettle in a constant temperature oven at 90°C for 6 hours and take it out. The samples were rinsed several times with absolute ethanol and deionized water successively, and dried at 60°C for later use.

[0066] (4) The formula of the organic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com