Method for utilizing ink-jet printing technology to prepare photonic crystal composite membrane with responsiveness and patterning

A technology of inkjet printing and photonic crystals, which is applied in the direction of copying/marking methods, household utensils, printing, etc., can solve the problems of widening photonic crystals, achieve low cost, simple process, and increase the speed of absorbing and releasing responsive substances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

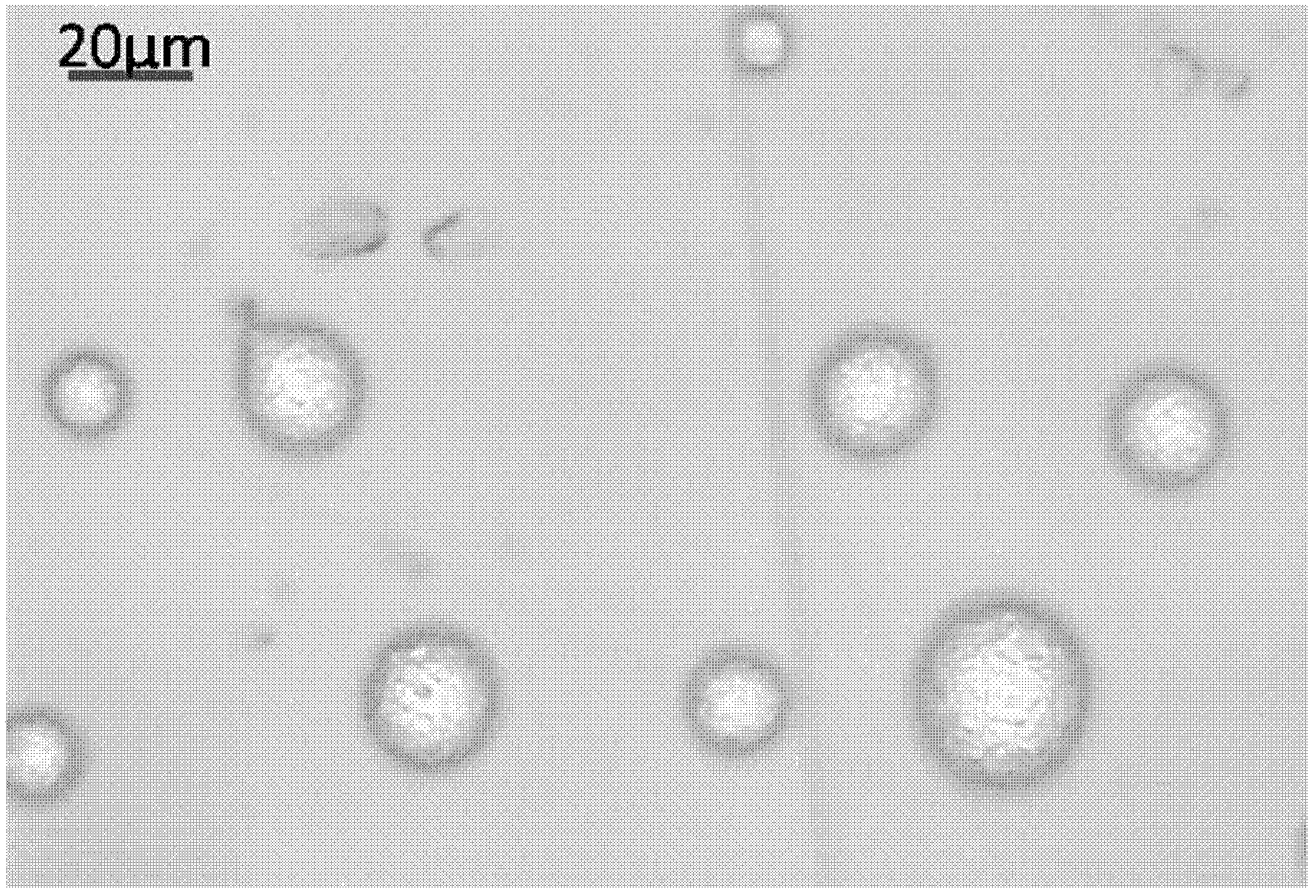

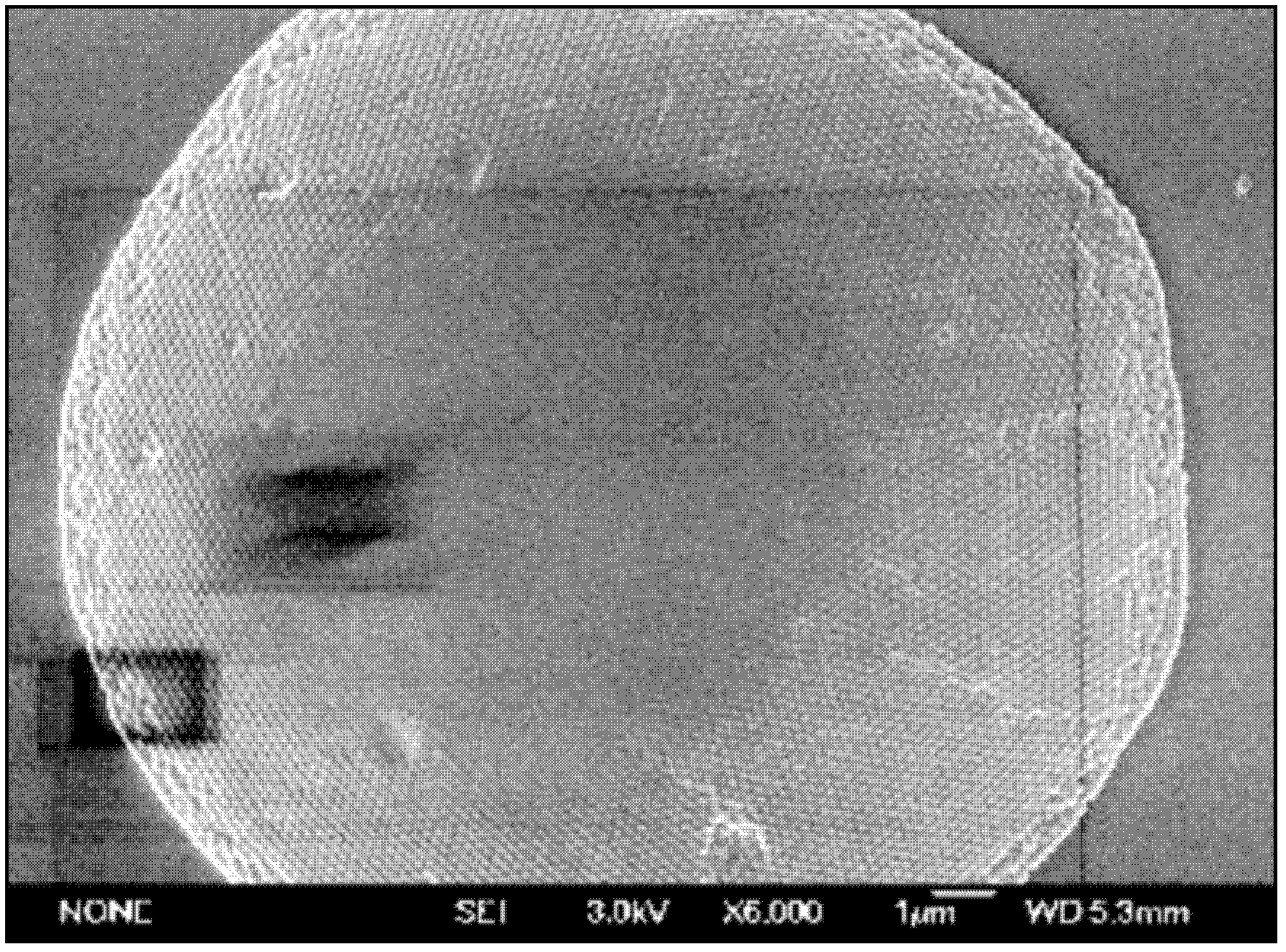

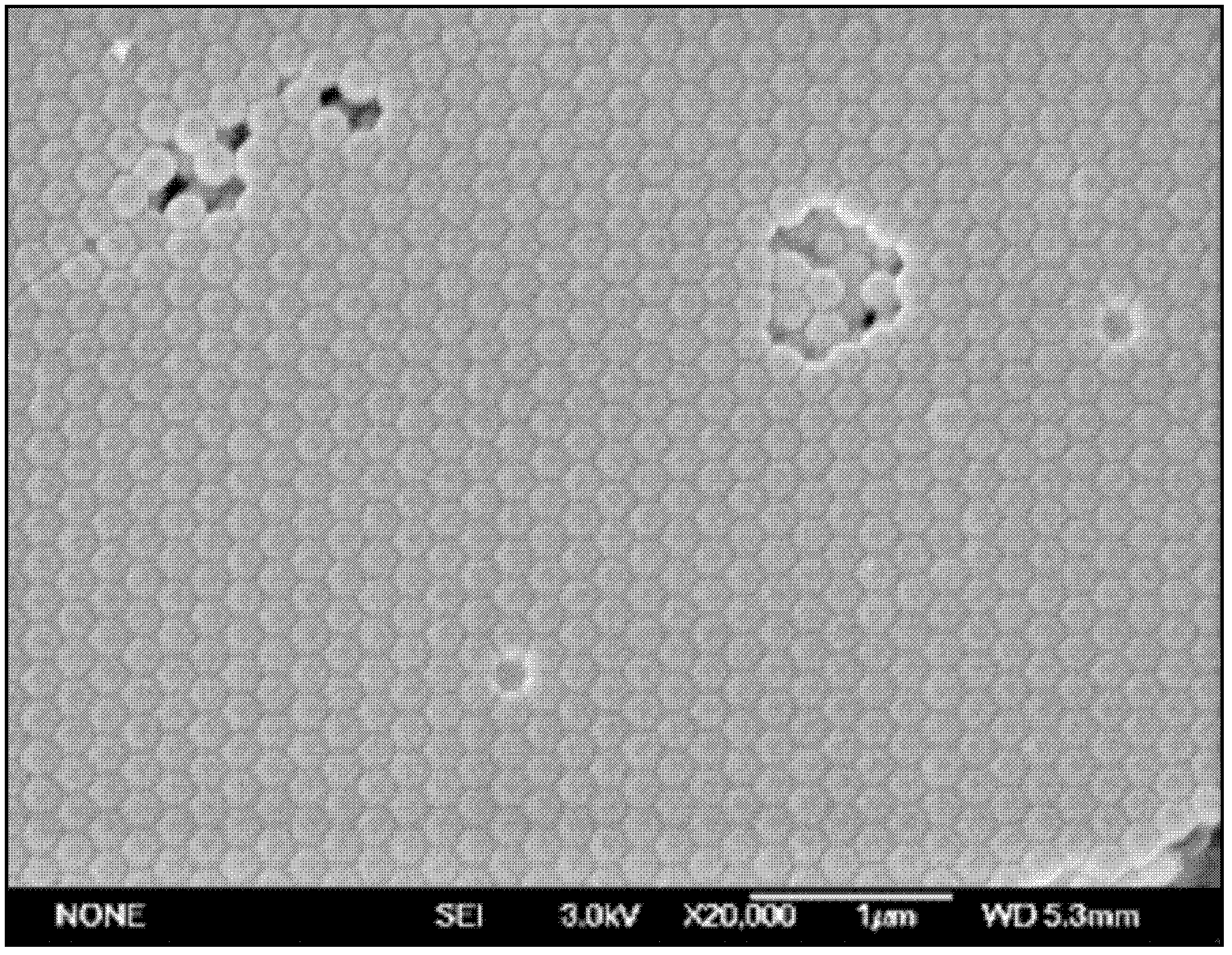

[0054] At a temperature of 10°C and a humidity of 20%, the monodisperse poly(styrene-methyl methacrylate-acrylic acid) triblock copolymer with a particle size of 100nm prepared by the method of patent No. ZL200510011219.2 Emulsion of latex particles, responsive functional monomer acrylamide, crosslinking agent N, N-methylenebisacrylamide, photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-propanone, high The boiling point additive ethylene glycol and water are mixed to obtain a mixed solution, wherein the content of the monodisperse poly(styrene-methyl methacrylate-acrylic acid) triblock copolymer latex particles in the mixed solution is 20wt%, and the responsive function unit The content of bulk acrylamide is 20wt%, the content of crosslinking agent N, N-methylenebisacrylamide is 5wt%, the content of photoinitiator 2-hydroxyl-2-methyl-1-phenyl-1-acetone 5wt%, the content of high-boiling additive ethylene glycol is 20wt%, and the balance is water; the above-mentioned mixed solution ...

Embodiment 2

[0058] At a temperature of 40°C and a humidity of 60%, commercially available monodisperse polymethyl methacrylate latex particles with a particle size of 1100 nm, responsive functional monomer acrylamide, and cross-linking agent N, N-methylene Bisacrylamide, thermal initiator water-soluble ammonium persulfate, high boiling point additive ethylene glycol and water are mixed to obtain a mixed solution, wherein the content of monodisperse polymethyl methacrylate latex particles in the mixed solution is 5wt%, and the response The content of the functional monomer acrylamide is 1wt%, the content of the crosslinking agent N, N-methylenebisacrylamide is 0.1wt%, the content of the thermal initiator water-soluble ammonium persulfate is 0.1wt%, the high boiling point The content of the auxiliary agent ethylene glycol is 30wt%, and the balance is water; the above-mentioned mixed solution is installed in the ink cartridge of an inkjet printer with a nozzle aperture of 100 μm, and the poly...

Embodiment 3

[0062]At a temperature of 20°C and a humidity of 40%, the monodisperse poly(styrene-methyl methacrylate-acrylic acid) triblock copolymer with a particle size of 180nm prepared by the method of patent No. ZL200510011219.2 Emulsion of latex particles, responsive functional monomer acrylamide, crosslinking agent N, N-methylenebisacrylamide, photoinitiator 2-hydroxy-2-methyl-1-phenyl-1-propanone, high The boiling point additive ethylene glycol and water are mixed to obtain a mixed solution, wherein the content of the monodisperse poly(styrene-methyl methacrylate-acrylic acid) triblock copolymer in the mixed solution is 20wt%, and the responsive functional monomer propylene The content of amide is 15wt%, crosslinking agent N, the content of N-methylenebisacrylamide is 2.5wt%, the content of photoinitiator 2-hydroxyl-2-methyl-1-phenyl-1-acetone is 2.5wt%, the content of high-boiling additive ethylene glycol is 40wt%, and the balance is water; the above-mentioned mixed solution is in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com