Method for preparing egg white lysozyme and active protein by adopting coseparation

A technology of egg white lysozyme and active protein, which is applied in the fields of biology, medicine and food industry, can solve the problems that are not conducive to co-separation and preparation of egg white active protein, the degree of deep processing is backward, and the large-scale application is limited, so as to achieve easy large-scale industrialization Production, short production cycle, and the effect of protecting biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

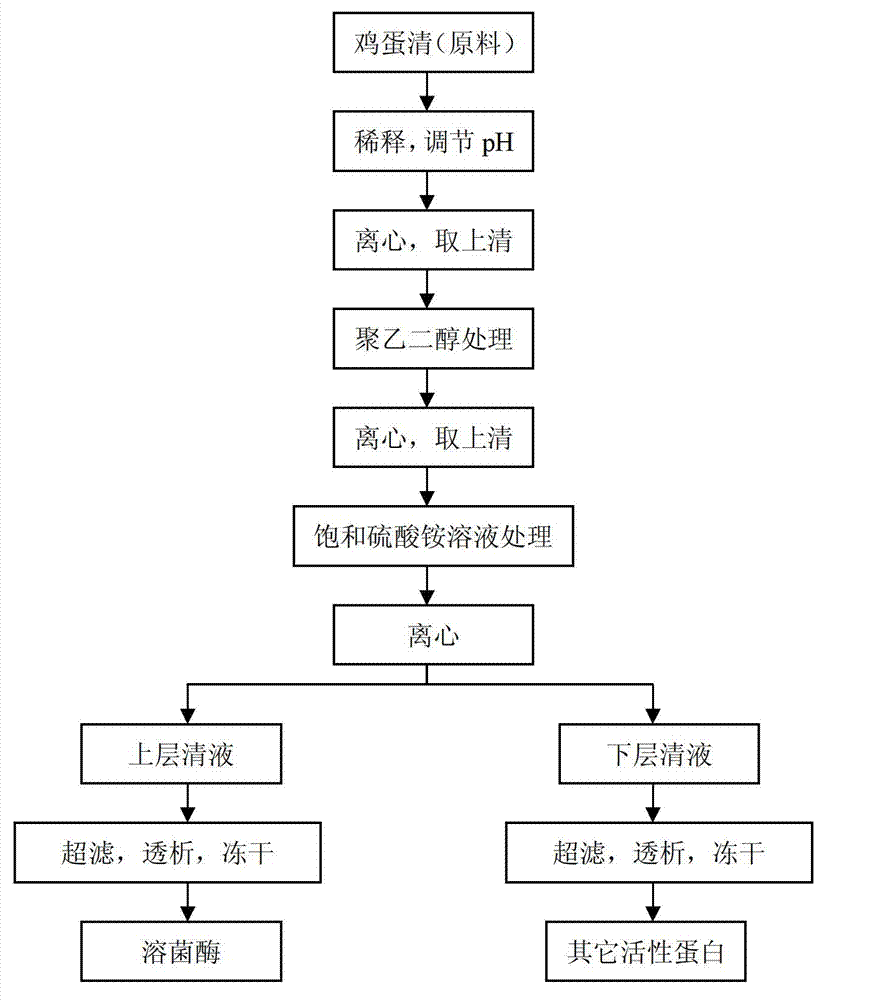

Method used

Image

Examples

Embodiment 1

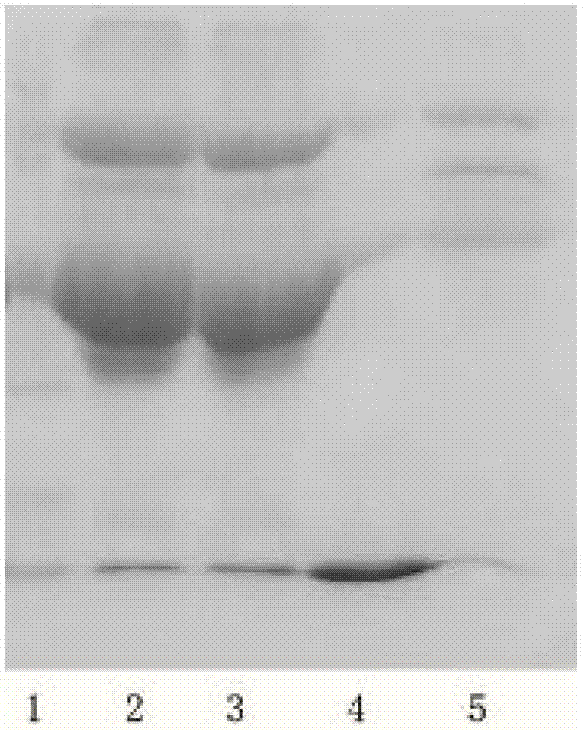

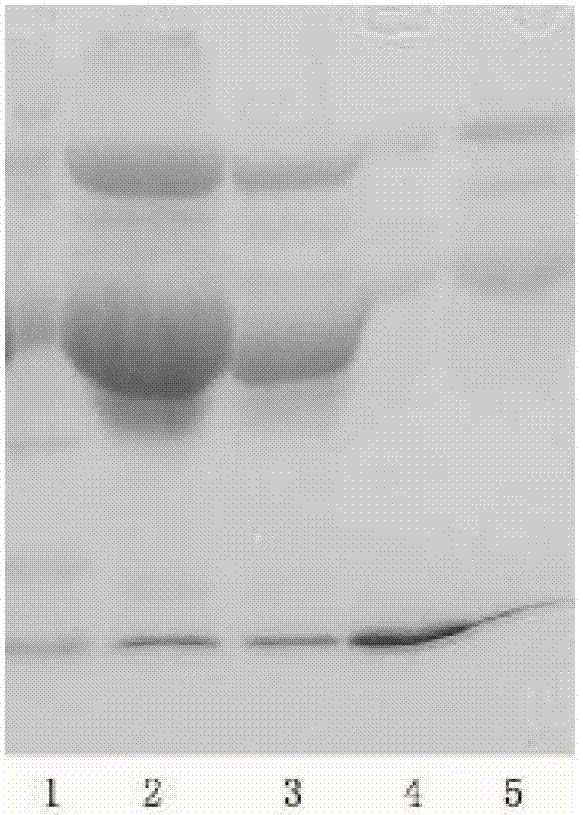

[0026] Add 100ml of fresh egg white, add 200ml of fresh deionized water, adjust the pH to about 5.5 with 1M hydrochloric acid, stir for 1 hour, and centrifuge at 8000rpm for 30min to remove the precipitate. The supernatant obtained by centrifugation was added with polyethylene glycol 200 until the mass concentration of polyethylene glycol was 10%, stirred evenly, left at room temperature for 1 hour, and centrifuged at 8000rpm for 30min to remove the precipitate. Add saturated ammonium sulfate solution to the supernatant obtained by centrifugation until the mass concentration of ammonium sulfate is 15%, stir evenly, place at room temperature for 1 hour, centrifuge at 6000rpm for 30min, and absorb the supernatant and the subnatant respectively. The supernatant was ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 3000-5000Da at room temperature, and the ultrafiltrate was subjected to vacuum freeze-drying, and the obtained white powder was lysozyme ...

Embodiment 2

[0028] Add 100ml of fresh egg white, add 200ml of fresh deionized water, adjust the pH to about 5.5 with 1M hydrochloric acid, stir for 1 hour, and centrifuge at 8000rpm for 30min to remove the precipitate. The supernatant obtained by centrifugation was added with polyethylene glycol 200 until the mass concentration of polyethylene glycol was 30%, stirred evenly, left at room temperature for 1 hour, and centrifuged at 8000rpm for 30min to remove the precipitate. Add saturated ammonium sulfate solution to the supernatant obtained by centrifugation until the mass concentration of ammonium sulfate is 15%, stir evenly, place at room temperature for 1 hour, centrifuge at 6000rpm for 30min, and absorb the supernatant and the subnatant respectively. The supernatant was ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 3000-5000Da at room temperature, and the ultrafiltrate was subjected to vacuum freeze-drying, and the obtained white powder was lysozyme ...

Embodiment 3

[0030] Add 100ml of fresh egg white, add 200ml of fresh deionized water, adjust the pH to about 5.5 with 1M hydrochloric acid, stir for 1 hour, and centrifuge at 8000rpm for 30min to remove the precipitate. The supernatant obtained by centrifugation was added with polyethylene glycol 20000 until the mass concentration of polyethylene glycol was 10%, stirred evenly, left at room temperature for 1 hour, and centrifuged at 8000rpm for 30min to remove the precipitate. Add saturated ammonium sulfate solution to the supernatant obtained by centrifugation until the mass concentration of ammonium sulfate is 15%, stir evenly, place at room temperature for 1 hour, centrifuge at 6000rpm for 30min, and absorb the supernatant and the subnatant respectively. The supernatant was ultrafiltered with an ultrafiltration membrane with a molecular weight cut-off of 3000-5000Da at room temperature, and the ultrafiltrate was subjected to vacuum freeze-drying, and the obtained white powder was lysozym...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com