Hydrophobic cellular metal organic skeleton for waste gas treatment and preparation method thereof

A technology of honeycomb metal and organic framework, applied in the direction of separation methods, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of reducing the adsorption capacity of honeycomb activated carbon, reducing the specific surface area of honeycomb activated carbon, increasing product cost, etc., to achieve low production cost , Increase lubricity, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

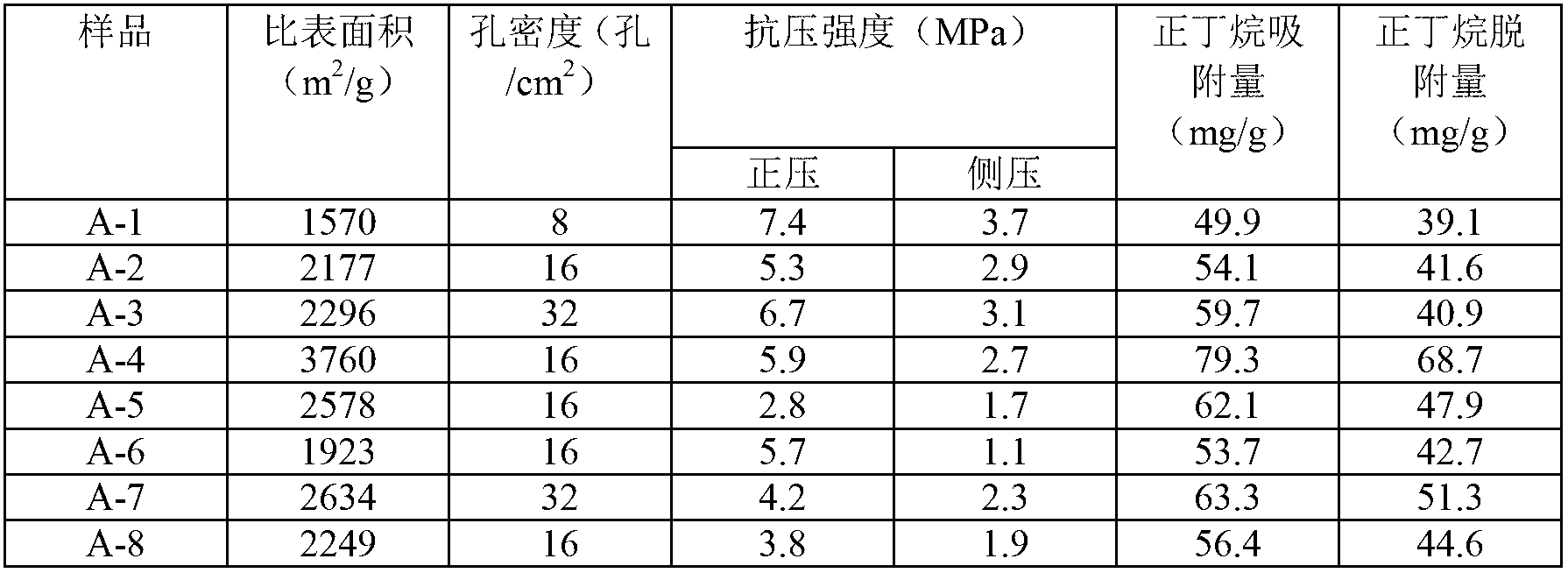

Embodiment 1

[0026] A method for preparing a hydrophobic honeycomb metal-organic framework for industrial waste gas treatment, comprising the following steps:

[0027] (1) Mix MIL-101 (Co), methylcellulose powder, polytetrafluoroethylene emulsion with a solid content of 20%, and water in a kneader at a mass ratio of 100:5:30:10 to make a plastic Mud.

[0028] (2) Put the plastic mud into the barrel of the vacuum extruder, start the vacuum system of the vacuum extruder, make the vacuum of the mud in the barrel reach 0.08MPa, and keep it under this vacuum for 10 minutes. Then extrude under the pressure of 20MPa to make a square honeycomb body as required. The side length and height of the square honeycomb body are 65 and 100 centimeters respectively, and the cell density of the honeycomb body is 8 holes / cm 2 .

[0029] (3) After drying the green honeycomb body at 100°C for 4 hours, dry it at 180°C for 6 hours to obtain a hydrophobic honeycomb metal-organic framework MIL-101(Co)(A-1).

[0...

Embodiment 2

[0032] A method for preparing a hydrophobic honeycomb metal-organic framework for industrial waste gas treatment, comprising the following steps:

[0033] (1) Mix MIL-101(Mn) powder, polyvinyl alcohol powder, polytetrafluoroethylene emulsion with a solid content of 20%, and water in a kneader at a mass ratio of 100:3:40:5 to make a plastic Mud.

[0034] (2) Put the plastic mud into the barrel of the vacuum extruder, start the vacuum system of the vacuum extruder, make the vacuum of the mud in the barrel reach 0.08MPa, and keep it under this vacuum for 10 minutes. Then extrude under the pressure of 20MPa to make a square honeycomb body as required. The side length and height of the square honeycomb body are 100 and 100 centimeters respectively, and the cell density of the honeycomb body is 16 holes / cm 2 .

[0035] (3) The honeycomb green body was dried at 150°C for 3 hours, and at 160°C for 10 hours to obtain a hydrophobic honeycomb MIL-101(Mn) (A-2).

[0036] Performance te...

Embodiment 3

[0038] A method for preparing a hydrophobic honeycomb metal-organic framework for industrial waste gas treatment, comprising the following steps:

[0039] (1) Mix MIL-101(Mn) powder, carboxymethyl cellulose powder, silicone-modified acrylic emulsion with a solid content of 18%, and water in a kneader at a mass ratio of 100:5:40:5, Made into plastic clay.

[0040] (2) Put the plastic mud into the barrel of the vacuum extruder, start the vacuum system of the vacuum extruder, make the vacuum of the mud in the barrel reach 0.085MPa, and keep it under this vacuum for 10 minutes. Then extrude under the pressure of 18MPa to make a cylindrical honeycomb body as required. The diameter and height of the cylindrical honeycomb body are 50cm and 100cm respectively, and the cell density of the honeycomb body is 32 holes / cm 2 .

[0041] (3) Dry the green honeycomb body at 100°C for 4 hours and at 180°C for 8 hours to obtain hydrophobic honeycomb MIL-101(Mn) (A-3).

[0042] Performance tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com