Additive for anisotropic conductive adhesives and preparation method thereof

An anisotropic, conductive adhesive technology, used in conductive adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of low conductivity, incomplete replacement, and great influence on bonding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

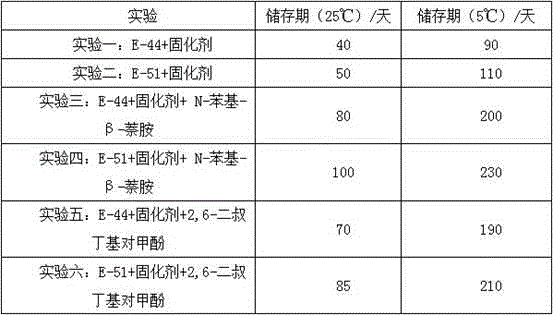

[0055] Epoxy resin will undergo curing reaction in the presence of curing agent. Even if latent curing agent is used under normal temperature and pressure, it will slowly polymerize, resulting in a gradual increase in viscosity and semi-curing or even curing, losing effectiveness. In order to improve the resin varnish For long-term storage stability, it is necessary to add stabilizers to the adhesive formulation. The purpose of this research is to study the influence of different stabilizers on the storage stability of epoxy resin adhesives, and to select the best stabilizer formulation.

[0056] Experimental Materials

[0057] Epoxy resin E-44 (by mass, the following examples are the same) 100 parts

[0058] Epoxy resin E-51 100 parts

[0059] Microencapsulated long-chain imidazole derivatives (latent curing agent) 57 parts

[0060] N-phenyl-β-naphthylamine (stabilizer) 5 parts

[0061] 2,6-Di-tert-butyl p-cresol (stabilizer) 5 parts

[0062] Mix 100g epoxy resin E-44 (or E-51), 57g m...

Embodiment 2

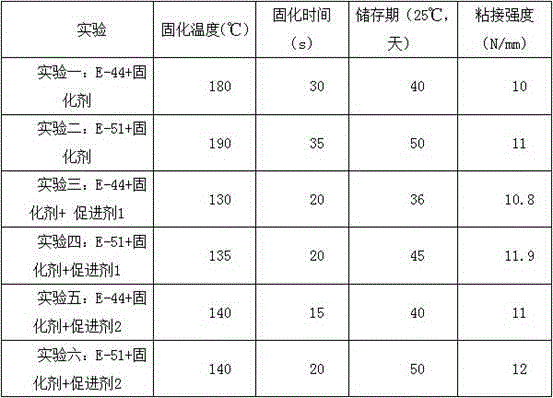

[0068] In the preparation of epoxy resin adhesive, the addition of curing accelerator can accelerate the curing reaction, reduce the curing temperature, and shorten the curing time. The addition of accelerators has a catalytic effect on the curing reaction. Most of them participate in the curing reaction and change the curing mechanism, thereby reducing the curing internal stress and improving the toughness, strength, heat resistance, and water resistance of the cured adhesive layer. The curing accelerator has the following categories: 1. Amine curing accelerator; 2. Substituted urea curing accelerator; 3. Imidazole and its salt curing accelerator; 4. Metal organic acid salt curing accelerator; 5. Phosphine compound Curing accelerator; 6. Boron trifluoride amine complex curing accelerator; 7. Composite nano TiO 2 Curing accelerator; 8. Phenolic curing accelerator. Considering its applicable curing system objects and comprehensive performance, this study selects 2,4,6-tris(dimet...

Embodiment 3

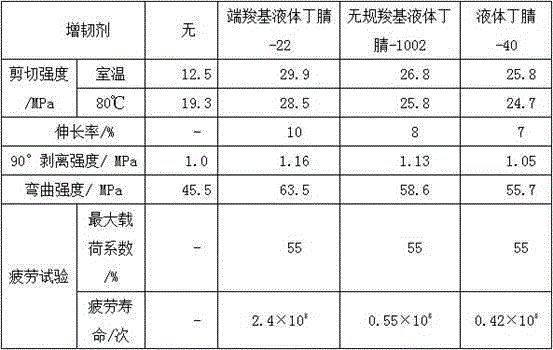

[0083] Unmodified thermosetting resin adhesives, such as epoxy resin and phenolic resin adhesives, have low elongation and greater brittleness after curing. When the bonding part is subjected to external force, it is easy to crack and quickly crack; it is not fatigue resistant and cannot be used as a structure Bonding. Therefore, we must try to reduce brittleness, increase toughness, and improve bearing strength. Any substance that can reduce brittleness and increase toughness without affecting other main properties of the adhesive can be called a toughening agent. Different from plasticizers, tougheners generally contain active groups, which can react with the resin, and are not completely compatible after curing. Sometimes there are phase separations to obtain ideal toughening effects and impact resistance. Obviously improved, while the heat distortion temperature dropped slightly.

[0084] Improved toughness can increase the impact strength by multiples or tens of times, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com