Quick-acting slow-released compound fertilizer and preparation method thereof

A compound fertilizer and slow-release technology, applied in the direction of fertilizer form, fertilizer mixture, fertilization device, etc., can solve the problems of high cost of polymer inert film, secondary pollution of soil environment, and inability to release nutrients, so as to achieve a wide application range of crops, Reduce the effect of excessive release and save equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

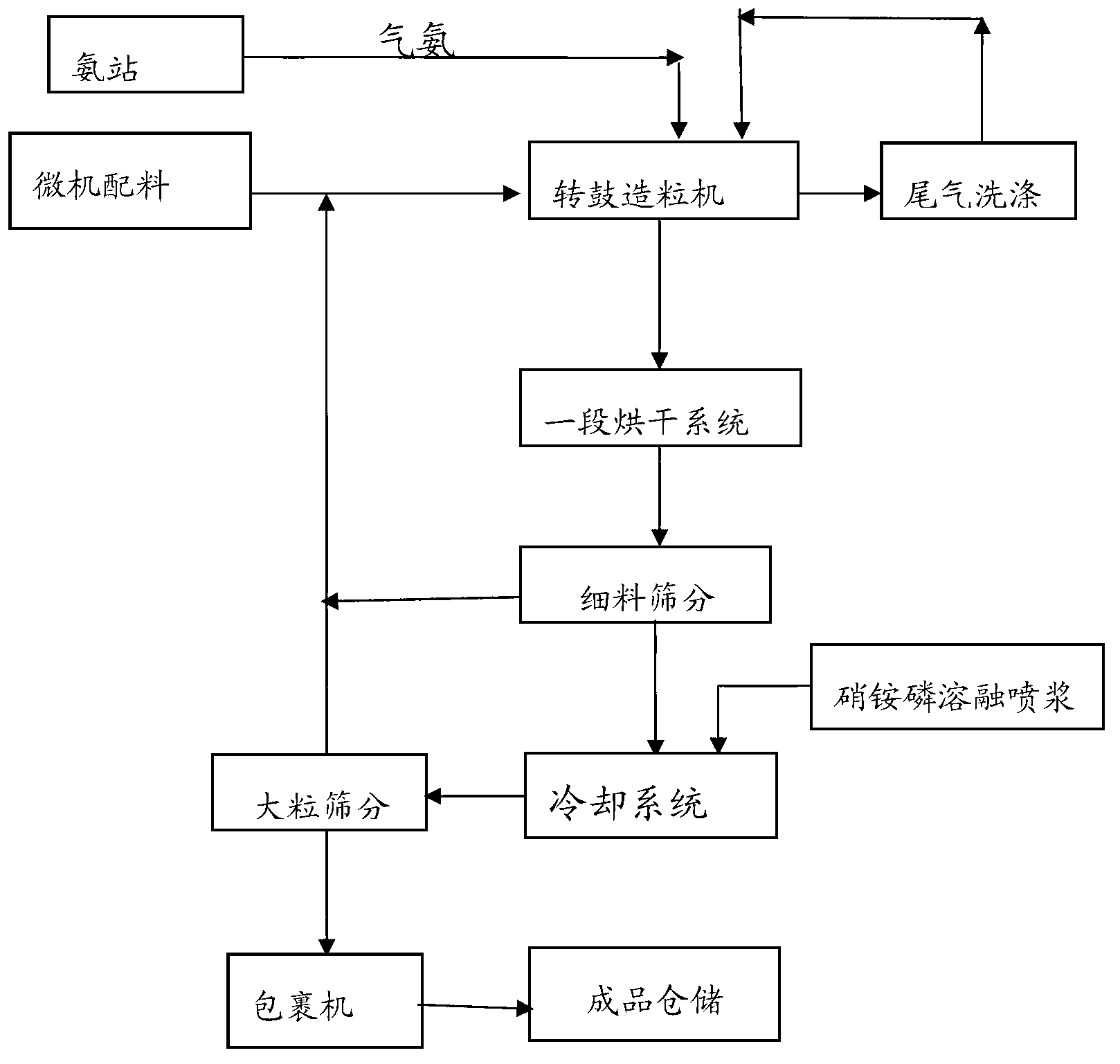

[0025] In the preparation method of the quick-acting slow-release compound fertilizer, in the production of the compound fertilizer by the granulation method, raw materials containing nitrate nitrogen, ammonium nitrogen, and amide nitrogen are added to the material, in order to prevent excessive nitric acid from being produced during the granulation process. Urea, the gaseous ammonia is directly passed into the material layer of the drum granulator to complete the ammonium treatment of ammonium nitrate, and granulate with urea and other powdery basic fertilizers containing nitrogen, phosphorus and potassium, and then dry after granulation , fine material sieving, ammonium nitrate phosphorus melt spraying, cooling, large material sieving, coating to obtain quick-acting slow-release compound fertilizer.

[0026] After the material is dried, the fine material is sieved, and the diameter of the sieve hole is between 2.0-3.0mm.

[0027] The ammonium nitrate is added in two parts, a...

Embodiment 1

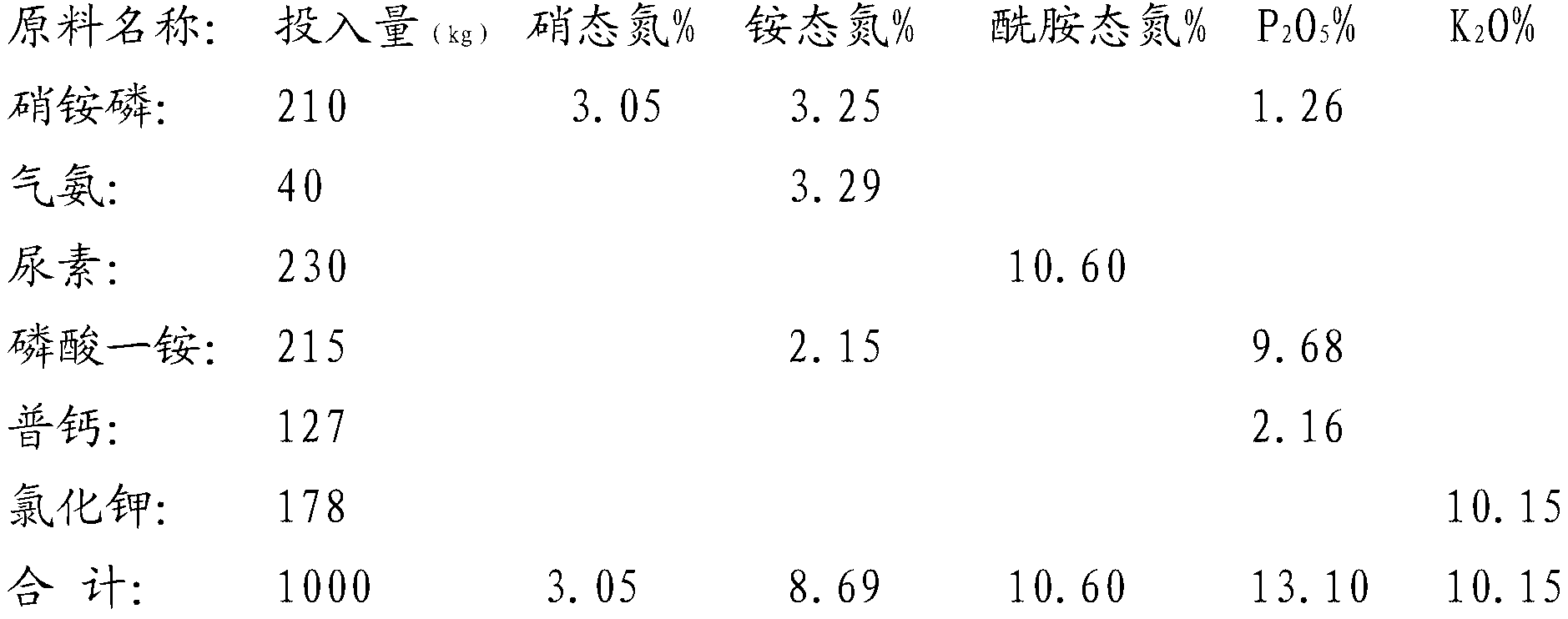

[0034] To prepare high-nitrogen products with nitrogen, phosphorus and potassium content of 22-13-10, take the raw material consumption quota of 1 ton product as an example:

[0035]

[0036] Specific production process: Add 40 kg of gaseous ammonia (containing N82.3%, mass percentage, the same below) to the material layer of the drum granulator after metering, and add ammonium nitrate phosphorus (containing N30% , which contains 14.5% nitrate nitrogen, 15.5% ammonium nitrogen, P 2 o 5 6%) 135 kg, urea (containing N46.2%) 230 kg, powdered monoammonium phosphate (containing N10%, P 2 o 5 45%) 215 kg, general calcium (including P 2 o 5 17%) 127 kg, potassium chloride (containing K 2 O57%) 178 kg, the above-mentioned powdery material and gas ammonia are mixed and granulated in the granulator. The tail steam washing water supplements the liquid phase required for granulation. The temperature of the material in the drum granulator is controlled at 60°C. After 3 minutes of ...

Embodiment 2

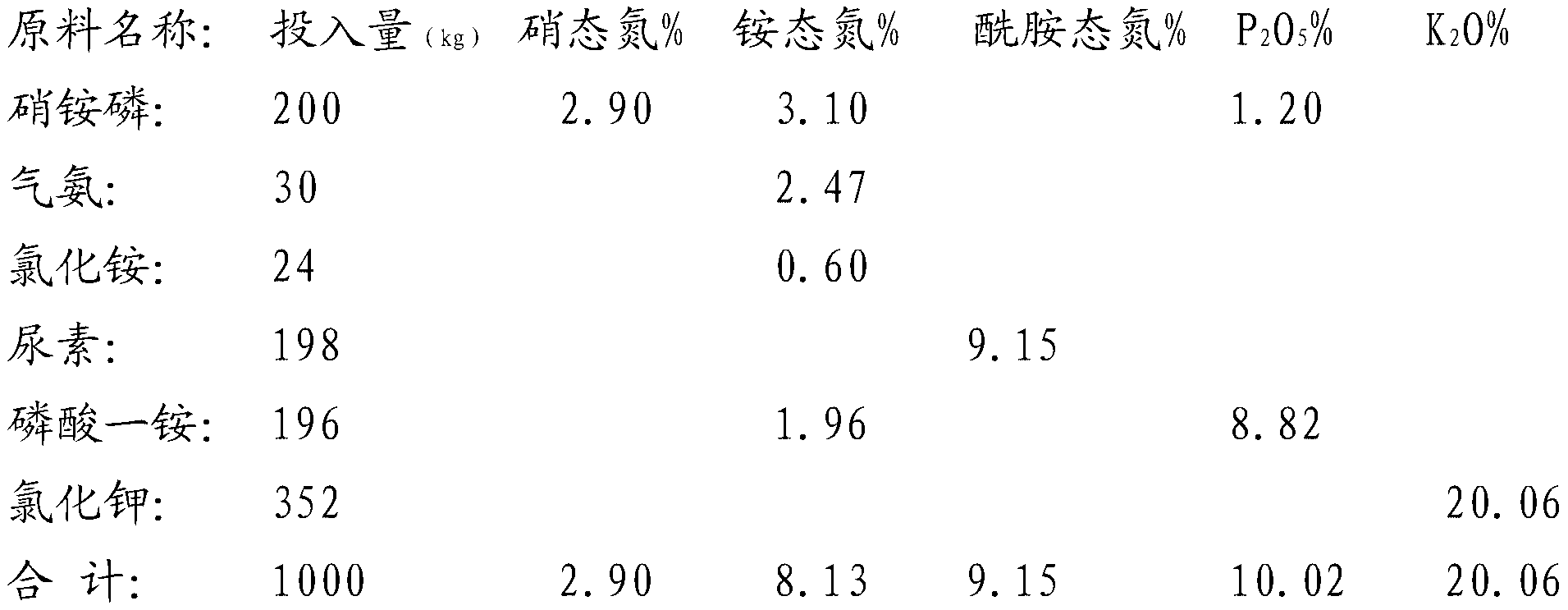

[0037] Embodiment 2: prepare nitrogen, phosphorus, potassium content 20-10-20 high-potassium product, take 1 ton of product raw material consumption quota as example:

[0038]

[0039] Specific production process: Add 30 kg of gaseous ammonia (containing N82.3%, mass percentage, the same below) to the material layer of the drum granulator after metering, and add ammonium nitrate phosphorus (containing N30% , which contains 14.5% nitrate nitrogen, 15.5% ammonium nitrogen, P 2 o 5 6%) 120 kg, ammonium chloride (including N 25.2 ) 24 kg, urea (containing N 46.2 ) 198 kg, powdered monoammonium phosphate (containing N10%, P 2 o 5 45%) 196 kg, potassium chloride (contains K 2 O57%) 352 kg, the above-mentioned powdery material and gas ammonia are mixed and granulated in the granulator. The tail steam washing water supplements the liquid phase required for granulation. The temperature of the material in the drum granulator is controlled at 70°C. After 4 minutes of granulation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com