Industrial product of hexadecyl xylol sulfonate and production method thereof, surfactant and application thereof

A technology of hexadecyl xylene sulfonate and hexadecyl xylene sulfonic acid, which can be used in the preparation of sulfonate, chemical instruments and methods, drilling compositions, etc., and can solve the interfacial tension of surfactants narrowing the range, affecting the oil displacement effect of ASP flooding, and worsening the interfacial activity of surfactants, achieving the effect of good interfacial activity, low cost and strong interfacial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

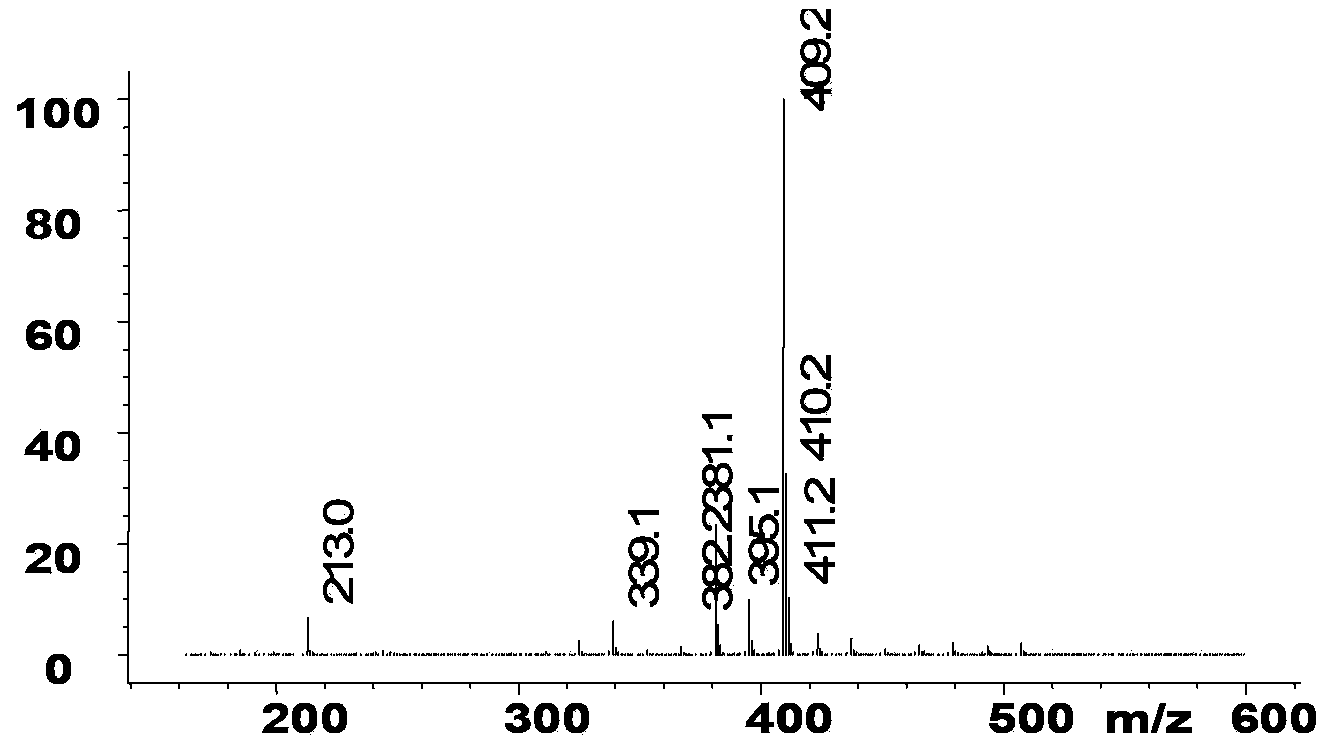

[0052] Embodiment 1, preparation cetyl dimethyl benzene sulfonate industrial product

[0053] The production of cetyldimethylbenzenesulfonate industrial product comprises the following steps:

[0054] 1) Preparation of cetyl xylene: select the carbon number as C 16 The linear olefins and xylene are used as raw materials to prepare hexadecyl xylene. The preparation method is (taking 3000L scale-up application test as an example): 1500Kg toluene, 38Kg main catalyst (aluminum trichloride) and 4L secondary catalyst (polyphosphoric acid ) into a 5000L reaction kettle, stirred for 10 minutes, slowly raised the temperature until white gas was generated in the system, stopped heating, and then added 640Kg hexadecene (α-olefin) into the reaction kettle, and turned on circulating water to cool when the temperature reached 40°C, and controlled the reaction temperature. Over 60°C, keep warm for 2h. After the heat preservation, stop stirring and settling for 10 minutes, the catalyst prec...

Embodiment 2

[0074] Embodiment 2, preparation cetyl dimethyl benzene sulfonate surfactant

[0075] In the application process of oil flooding, the surfactant is required to have good fluidity, so in the industrial product (mixed solution) of sodium cetylxylene sulfonate prepared in Example 1, add a cosolvent to dilute it to obtain a product that can be used directly. Cetyldimethylbenzenesulfonate surfactant in oil flooding complex system. The auxiliary solvent can be ethanol, propanol, isopropanol or isobutanol, and the amount added is 15-20wt% of the total amount of surfactants. The amount of auxiliary solvent added should not have an upper limit technically, but considering the cost, it should not exceed 20% is the most economical.

[0076] The present invention finally obtains the surfactant-hexadecylxylene sulfonate surfactant that can be applied in the mine field, and its main composition is 50-55wt% hexadecylxylene sulfonate, 15-20wt% alcohol , unsulfonated oil (unreacted alkylbenz...

Embodiment 3

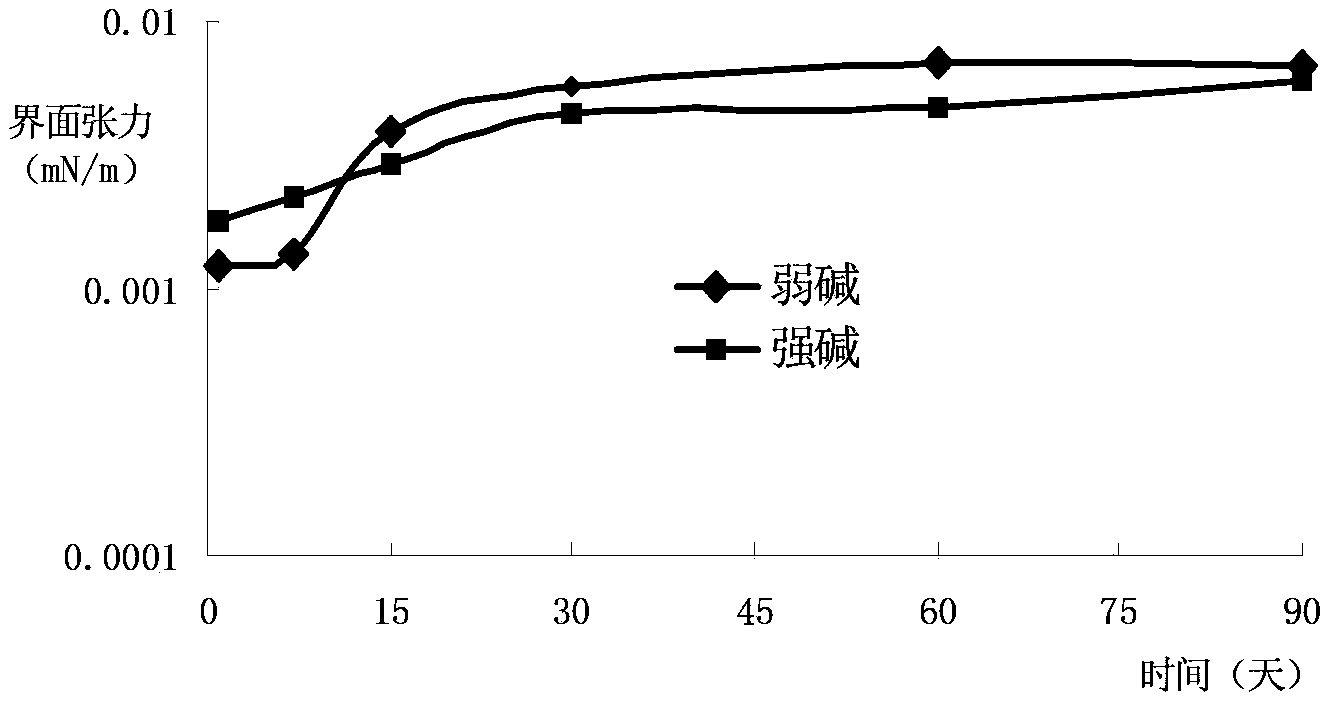

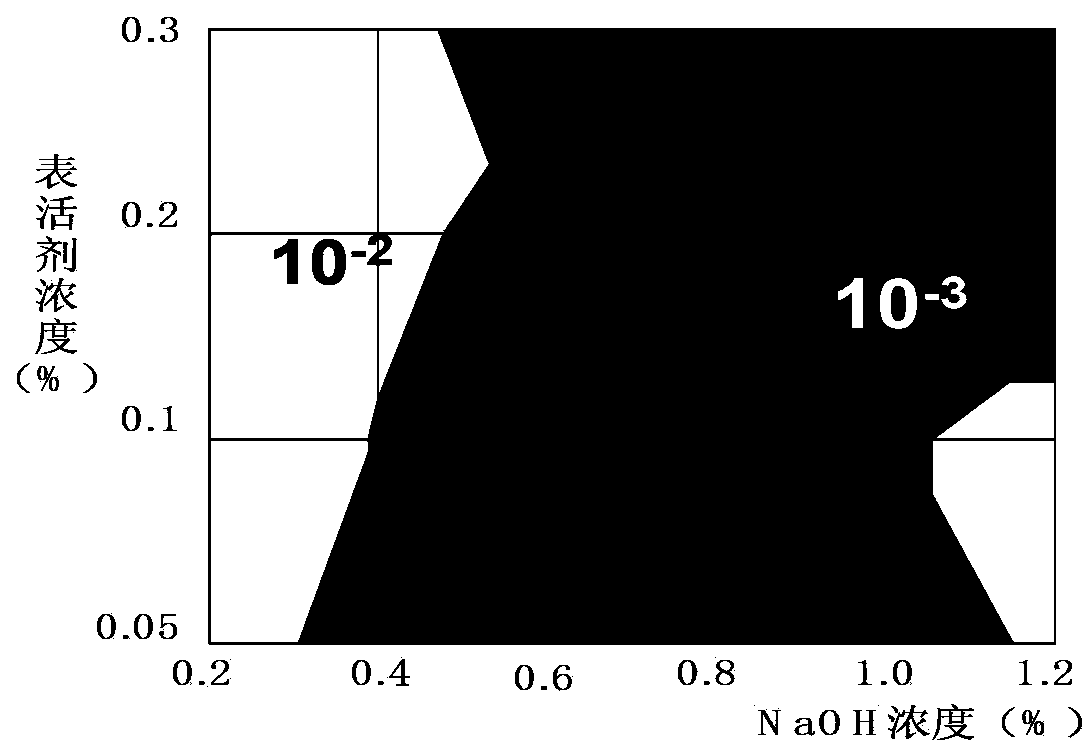

[0077] Embodiment 3, the performance detection of hexadecyl xylene sulfonate surfactant of the present invention

[0078] The hexadecyl xylene sulfonate surfactant prepared in embodiment 2 is mixed with two kinds (strong base NaOH, weak base NaOH) 2 CO 3 ) three-component chemical composite flooding system, and the interfacial tension between the composite flooding system and Daqing crude oil was measured. During the measurement, the crude oil is the wellhead degassed crude oil, and the water is the injection water; the experimental temperature is 45°C; the test instrument: the University of Texas spinning drop tensiometer, model 500.

[0079] System 1: strong base system, the measured interface activity see Figure 2A .

[0080] Surfactant: hexadecyl xylene sulfonate surfactant (take n-butanol as an example with 15% addition of n-butanol), injection concentration of 0.05wt%-0.3wt% in the ternary composite system;

[0081] Alkali: strong alkali sodium hydroxide, injected i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| effective permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com