Preparation method of FER (Ferritin) zeolite molecular sieve with high silica-alumina ratio

A technology of zeolite molecular sieve and high silicon-aluminum ratio, applied in the direction of crystalline aluminosilicate zeolite, etc., can solve problems such as environmental pollution, narrow synthesis interval, waste of resources, etc., reduce production cost and environmental pollution, and improve the utilization of silicon rate, the effect of reducing the loss of silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 2.59g CH 3 Add COOK and 1.59g NaOH solid to 80ml of deionized water, stir until the solution becomes clear, add 1.32g sodium metaaluminate to the above solution, and continue stirring at room temperature until the solid is completely dissolved. Add 13.8 g of fuming silica gel to the above mixed solution, continue to stir strongly magnetically for 1 hour, then add 1.38 g of FER zeolite molecular sieve into the reaction system as a seed crystal, continue stirring for 0.5 hour after the addition, and finally put the mixture into the poly In a tetrafluoroethylene-lined stainless steel crystallization kettle, airtightly crystallize in a microwave oven at 150 °C for 24 hours, and obtain a solid product after conventional suction filtration, washing, and drying. The molar composition of the initial sol of the mixture is: SiO 2 :Al 2 o 3 =30, Na 2 O:SiO 2 =0.25,H 2 O:SiO 2 =20.

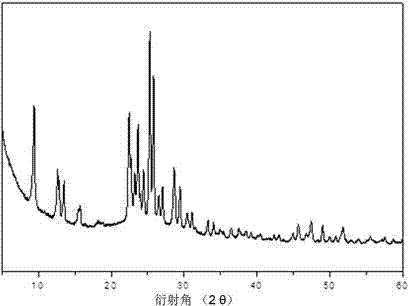

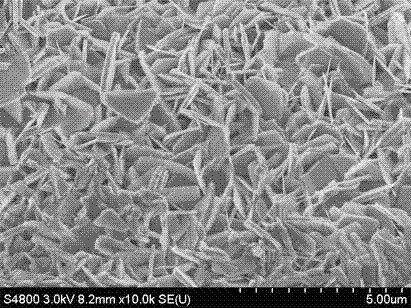

[0024] The solid product is FER type zeolite through X-ray analysis, and finally obtained...

Embodiment 2

[0026] Except that column chromatography silica gel was used instead of the fumed silica gel in Example 1 as the silicon source, other preparation conditions were the same as in Example 1.

[0027] The solid product is analyzed as FER type zeolite by X-ray analysis, and the finally obtained FER sheet-shaped zeolite molecular sieve.

Embodiment 3

[0029] Except that Qingdao silica gel was used instead of the fumed silica gel in Example 1 as the silicon source, other preparation conditions were the same as in Example 1.

[0030] The solid product is analyzed as FER zeolite by X-ray analysis, and finally obtained FER flake zeolite molecular sieve has a silicon-aluminum ratio of 25.0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com