Printing adhesive of stone paper wallpaper and preparation method of printing adhesive

A technology of adhesive and stone paper, which is applied in the fields of dyeing, textiles and papermaking, can solve the problems that affect the printing effect, the printing adhesive is difficult to meet the application requirements, and the adhesive production technology has not been disclosed. Effects of improving stain resistance, improving wet and dry rub resistance, improving hardness and surface slipperiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

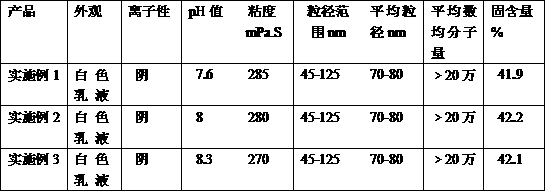

Examples

Embodiment 1

[0035] Raw material ratio: fatty alcohol polyoxyethylene ether (Pingping plus O-25) 2 . 3 grams, sodium lauryl sulfate 2 . 8 grams, methyl acrylate 26 grams, ethyl acrylate 67 grams, glycidyl methacrylate 4 . 5 grams, vinyl acetate 12 grams, methyl methacrylate 14 grams, acrylic acid 3 . 3 g, ethylene urea ethoxy methacrylate 4 . 2 g, ammonium persulfate 1 . 2 g, sodium bisulfite 0 . 6 grams, 178 grams of deionized water;

[0036] Process method:

[0037] 1) Mix all the monomers, namely 26 grams of methyl acrylate, 67 grams of ethyl acrylate, and 4 grams of glycidyl methacrylate . 5 grams, vinyl acetate 12 grams, methyl methacrylate 14 grams, acrylic acid 3 . 3 g, ethylene urea ethoxy methacrylate 4 . Add 2 grams into the mixing tank and stir well;

[0038] 2) Add 52 grams of deionized water, fatty alcohol polyoxyethylene ether (Pingping plus O-25) 0 . 7 grams, sodium lauryl sulfate 0 . 7 grams, fully stirred to dissolve;

[0039] 3) Ammonium persulfate 1 . 2 ...

Embodiment 2

[0047] Raw material ratio: fatty alcohol polyoxyethylene ether (Pingping plus O-25) 2 . 5 grams, sodium lauryl sulfate 2 . 6 grams, methyl acrylate 28 grams, ethyl acrylate 65 grams, glycidyl methacrylate 4 . 3 grams, vinyl acetate 14 grams, methyl methacrylate 12 grams, acrylic acid 3 . 9 g, ethylene urea ethoxy methacrylate 4 . 5 g, ammonium persulfate 1 . 3 g, sodium bisulfite 0 . 65 grams, 182 grams of deionized water.

[0048] Process method:

[0049] 1) Mix all the monomers, namely 28 grams of methyl acrylate, 65 grams of ethyl acrylate, and 4 grams of glycidyl methacrylate. 3 grams, vinyl acetate 14 grams, methyl methacrylate 12 grams, acrylic acid 3 . 9 g, ethylene urea ethoxy methacrylate 4 . Add 5 grams into the mixing tank and stir well;

[0050] 2) Add 55 grams of deionized water, fatty alcohol polyoxyethylene ether (Pingping plus O-25) into the reaction kettle . 8 grams, sodium lauryl sulfate 0 . 6 grams are fully stirred and dissolved;

[0051] 3) ...

Embodiment 3

[0059] Raw material ratio: fatty alcohol polyoxyethylene ether (Pingping plus O-25) 2 . 9 grams, sodium lauryl sulfate 2 . 2 grams, methyl acrylate 27 grams, ethyl acrylate 66 grams, glycidyl methacrylate 4 . 7 grams, vinyl acetate 13 grams, methyl methacrylate 13 grams, acrylic acid 4 . 8 g, ethylene urea ethoxy methacrylate 4 . 6 g, ammonium persulfate 1 . 4 g, sodium bisulfite 0 . 7 grams, 185 grams of deionized water.

[0060] Process method:

[0061] 1) Mix all the monomers, namely 27 grams of methyl acrylate, 66 grams of ethyl acrylate, and 4 grams of glycidyl methacrylate . 7 grams, vinyl acetate 13 grams, methyl methacrylate 13 grams, acrylic acid 4 . 8 g, ethylene urea ethoxy methacrylate 4 . Add 6 grams into the mixing tank and stir well;

[0062] 2) Add 58 grams of deionized water, fatty alcohol polyoxyethylene ether (Pingping plus O-25) 0 . 7 grams, sodium lauryl sulfate 0 . 8 grams are fully stirred and dissolved;

[0063] 3) Ammonium persulfate 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com