A modified amylose-based nanohelical oil-phase triggered immediate-release body and its preparation method

A technology of amylose and oil phase, which is applied in the direction of medical preparations containing non-active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc. It can solve the problem of onset time, prolonged clearance time, and poor emulsification stability of fat microemulsion , Fat emulsion is easy to breed bacteria and other problems, to achieve the effect of improving hydrophilic performance, not easy to leak, and excellent reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

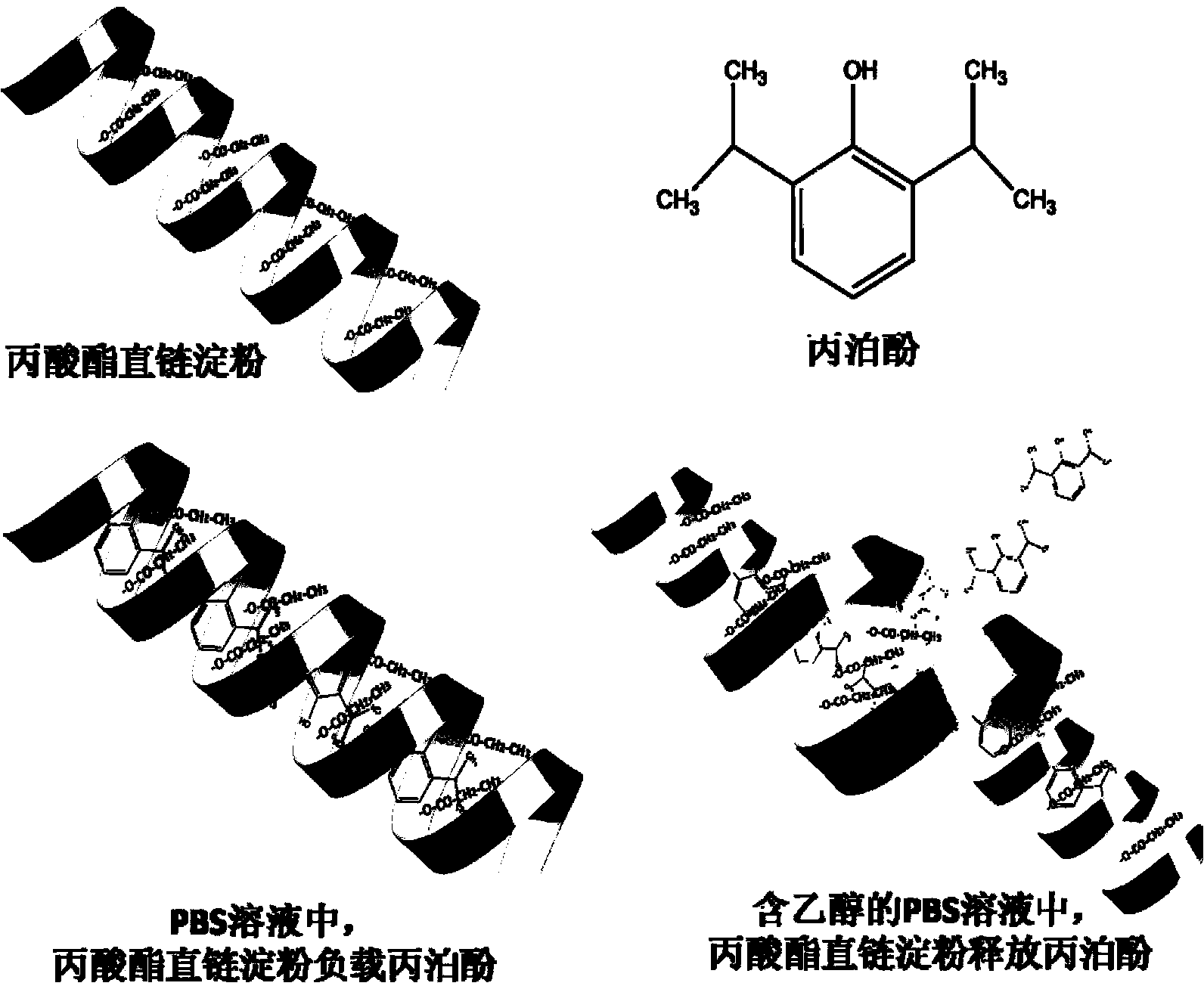

[0037] see figure 2 , the preparation method of the nano-spiral oil phase triggered immediate-release body based on modified amylose comprises the following steps:

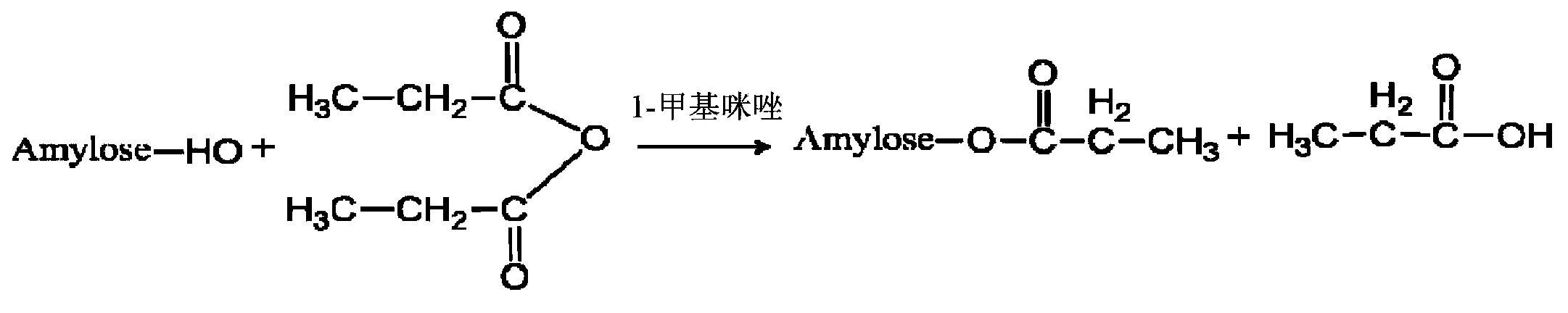

[0038] 1) Preparation of propionate amylose

[0039] Dissolve 1 g of amylose in 50 mL DMSO solution at 80 °C, stir for 1 h, add 0.3 mL of propionic anhydride and 0.2 mL of 1-methylimidazole, react at 80 °C for 4 h, and collect propionate amylose by acetone precipitation and suction filtration.

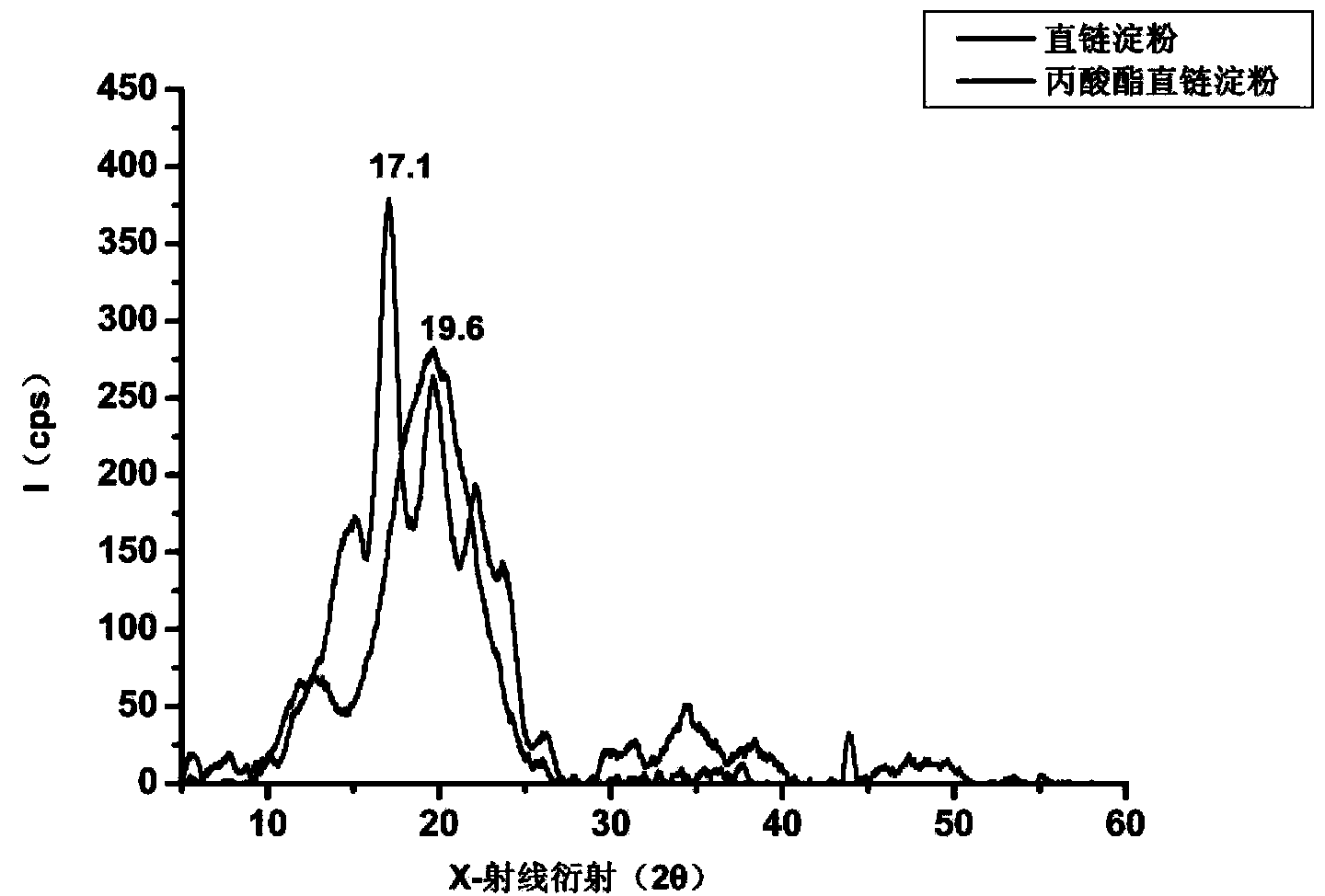

[0040] Identification of the helical structure of propionate amylose:

[0041] like image 3 X-ray diffraction patterns of amylose and propionate amylose are shown. The characteristic peaks of amylose are 14.9, 17.1, 19.6, 22.1, 23.7, etc., which are the characteristic peaks of type B-starch crystallization, that is, loose crystals; while the characteristic peaks of propionate amylose are 7.8, 12.7, 19.6, respectively. It is the characteristic peak of V-starch crystallization, namely spiral crystallization.

[0042] ...

Embodiment 2

[0045] The preparation method of the nano-spiral oil phase triggered immediate-release body based on modified amylose comprises the following steps:

[0046] 1) Preparation of propionate amylose

[0047] Dissolve 1 g of amylose in 50 mL of DMSO solution at 60 °C, stir for 1 h, add 0.2 mL of propionic anhydride and 0.1 mL of 1-methylimidazole, react at 60 °C for 8 h, and collect propionate amylose by acetone precipitation and suction filtration.

[0048] 2) Preparation of propofol propofol nano-helix immediate release on amylose propionate

[0049] Disperse 20 mg of propionate amylose in 20 mL of pH 7.4 PBS solution, drop 100 mg of propofol into the solution, and stir magnetically for 15 min. The starch solution loaded with propofol was poured into a dialysis bag with a pore size of 5000D, placed in a 1L PBS solution for 2h dialysis, and the dialysate was changed twice in between to remove free propofol. Aspirate the liquid in the dialysis bag, filter it with a 200nm syringe fi...

Embodiment 3

[0051] The preparation method of the nano-spiral oil phase triggered immediate-release body based on modified amylose comprises the following steps:

[0052] 1) Preparation of propionate amylose

[0053] Dissolve 1 g of amylose in 50 mL of DMSO solution at 90 °C, stir for 1 h, add 0.3 mL of propionic anhydride and 0.15 mL of 1-methylimidazole, react at 90 °C for 3 h, and collect propionate amylose by acetone precipitation and suction filtration.

[0054] 2) Preparation of propofol propofol nano-helix immediate release on amylose propionate

[0055] 20 mg of propionate amylose was dispersed in 20 mL of pH 7.4 PBS solution, 80 mg of propofol was dropped into the solution, and the solution was magnetically stirred for 15 min. The starch solution loaded with propofol was poured into a dialysis bag with a pore size of 5000D, placed in a 1L PBS solution for 2h dialysis, and the dialysate was changed twice in between to remove free propofol. Aspirate the liquid in the dialysis bag,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com