High-yield production method of GABA (gamma amino butyric acid) through mixed fermentation of brevibacterium tianjinese and lactobacillus plantarum

A technology of Lactobacillus plantarum and Brevibacterium tianjini, applied in the fields of fermentation engineering and enzyme engineering, can solve problems such as lack of γ-aminobutyric acid synthesis pathway, and achieve the effects of improving production efficiency, reducing production cost and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: culture medium, is described as follows:

[0021] (1) Brevibacterium tianjin SW07-1

[0022] ①Activation medium: peptone 1, yeast extract 0.5, NaCl1, glucose 0.5, sterilized at 115°C for 15 minutes; ②Seed medium: glucose 30, corn steep liquor 25, KH 2 PO 4 ·3H 2 O1.5, MgSO 4 ·7H 2 O0.4, urea 6 (diluted), pH7.0-7.2, sterilized at 115°C for 15 minutes; ③Fermentation medium (g / L): glucose 140, corn steep liquor 3, urea 5.5 (dissolved), KH 2 PO 4 ·3H 2 O1.5, MgSO 4 ·7H 2 O0.8, MnSO 4 ·H 2 O0.02, FeSO 4 ·7H 2 O0.02, biotin 8×10 -5 , L-histidine 5×10 -4 , pH7.0-7.2, sterilized at 115°C for 15min.

[0023] (2) L. plantarum GB01-21

[0024]①Activation medium (g / L): MRS medium. Casein peptone 10, beef extract 10, yeast extract 5, glucose 5, sodium acetate 5, diamine citrate 0.2, Tween 0.1, dipotassium hydrogen phosphate 0.2, magnesium sulfate 0.2, manganese sulfate 0.05, calcium carbonate 20, pH6 .5, sterilized at 115°C for 15 minutes; ②Seed mediu...

Embodiment 2

[0025] Example 2: Glutamic acid fermentation of Brevibacterium tianjin SW07-1 and collection of L.plantarum GB01-21

[0026] Cultivation of the glutamic acid-producing strain Brevibacterium tianjin SW07-1: Inoculate the preserved strain into the activation medium, 30°C, 220r / min reciprocating shaker shake culture for 12h, and then inoculate the seed medium with 2% inoculum , 30°C, 220r / min reciprocating shaker for 12h. Then inoculate into 5L fermenter with 10% inoculum amount. The liquid volume in the fermenter is 2.5L, the ventilation rate is 3.5L / min, the pH is controlled by feeding ammonia water to control pH7.0-7.2, the speed is adjusted to 400-600r / min according to the dissolved oxygen demand, and the culture is carried out at 30°C for 36h. By adding an appropriate amount of glucose, the final glutamic acid content in the fermentation broth is about 90g / L.

[0027] Collection of Lactobacillus plantarum: Inoculate the preserved strains into the activated medium MRS mediu...

Embodiment 3

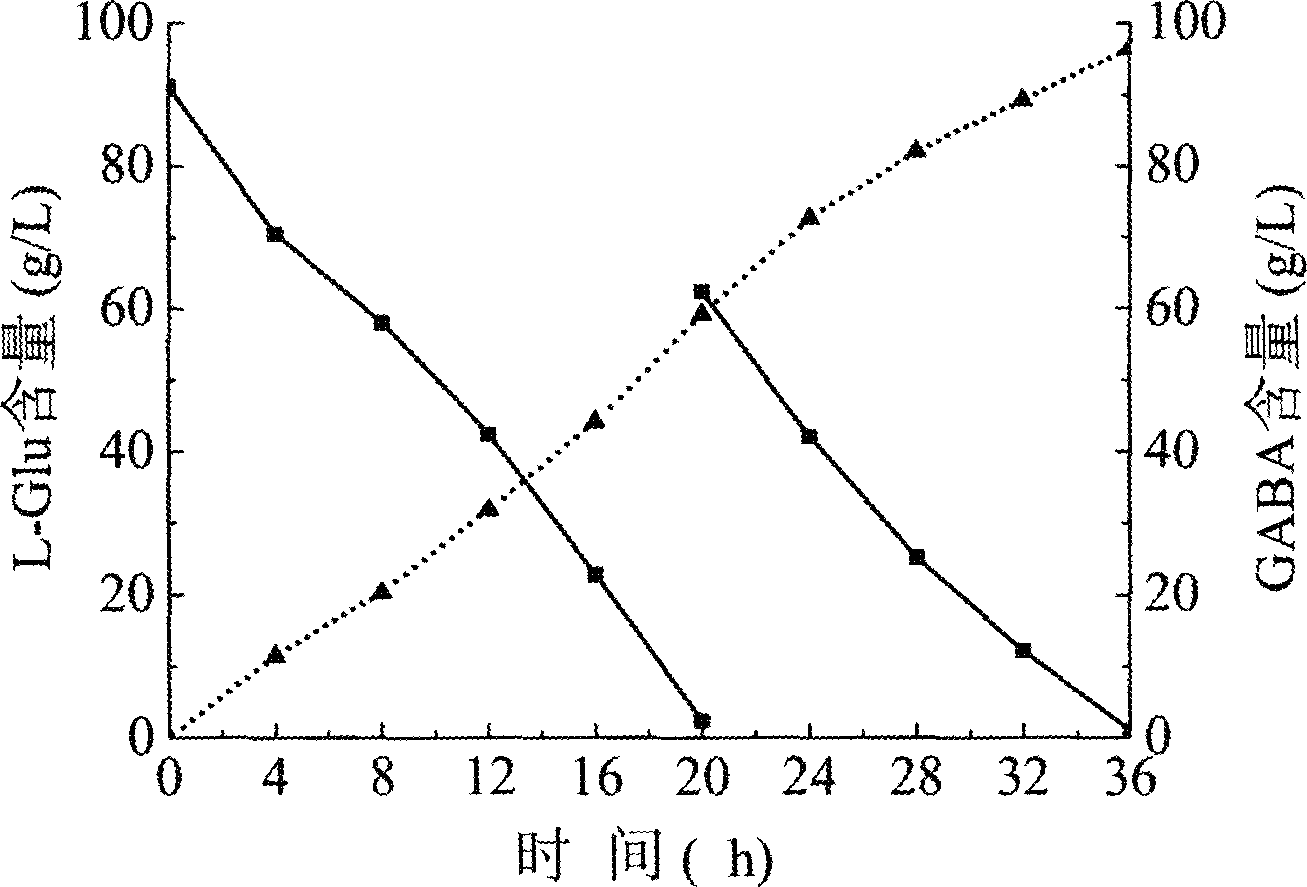

[0028] Embodiment 3: direct conversion of glutamic acid fermentation broth

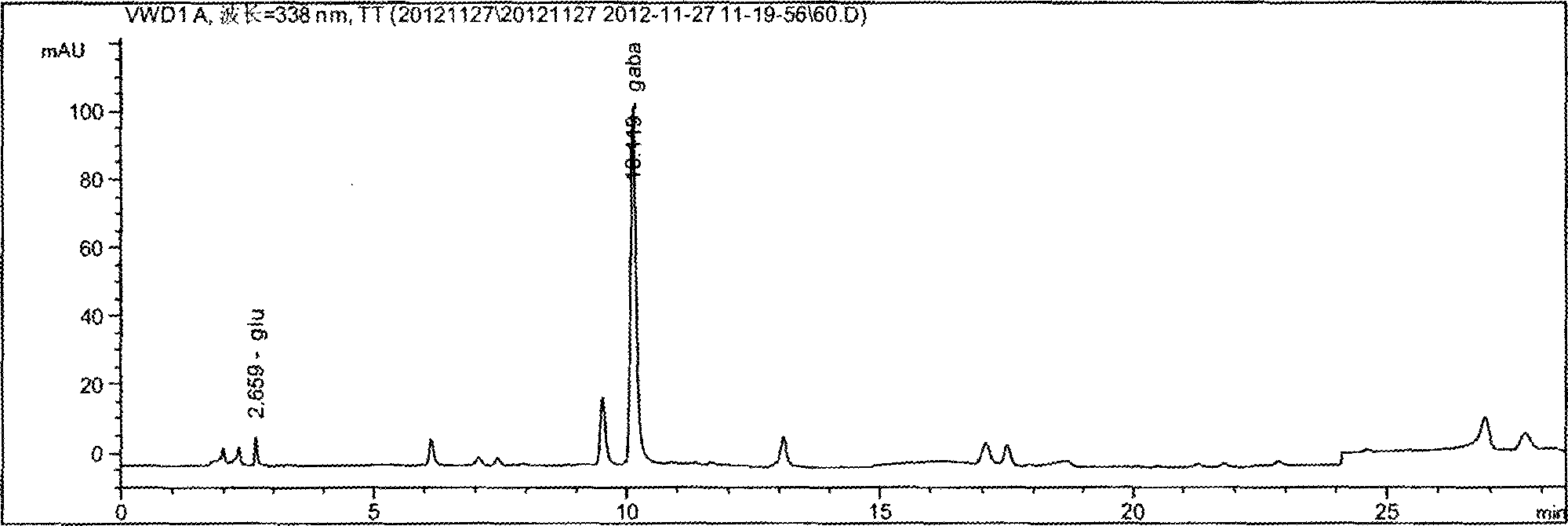

[0029] Add the corresponding amount of anhydrous sodium acetate and glacial acetic acid to Brevibacterium tianjin SW07-1 glutamic acid fermentation liquid according to the preparation method of acetic acid buffer to form a 0.2mol / L, pH 5.0 acetic acid buffer system. At the same time, add the plantaractobacillus collected in the previous step into the buffer system (the amount of added thalli is calculated according to the volume of plantaractobacillus culture solution: the volume of glutamic acid fermentation solution = 3: 2), as the transformation system, the stirring speed and aeration rate were 150r / min and 0.5L / min, respectively, and transformed at 30°C, and the residual glutamic acid content in the fermentation broth was regularly detected. like figure 1 Shown is the change curve of the original glutamic acid content in the glutamic acid fermentation broth during the conversion process, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com