Biogenic pesticide containing xanthoxylin and abamectin and preparation method thereof

A bio-sourced pesticide and abamectin technology, applied in botany equipment and methods, biocides, animal repellents, etc., can solve problems such as environmental pollution, poor stability of insecticide efficacy, waste, etc., and achieve insecticide Wide range, obvious synergistic effect, and low application concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

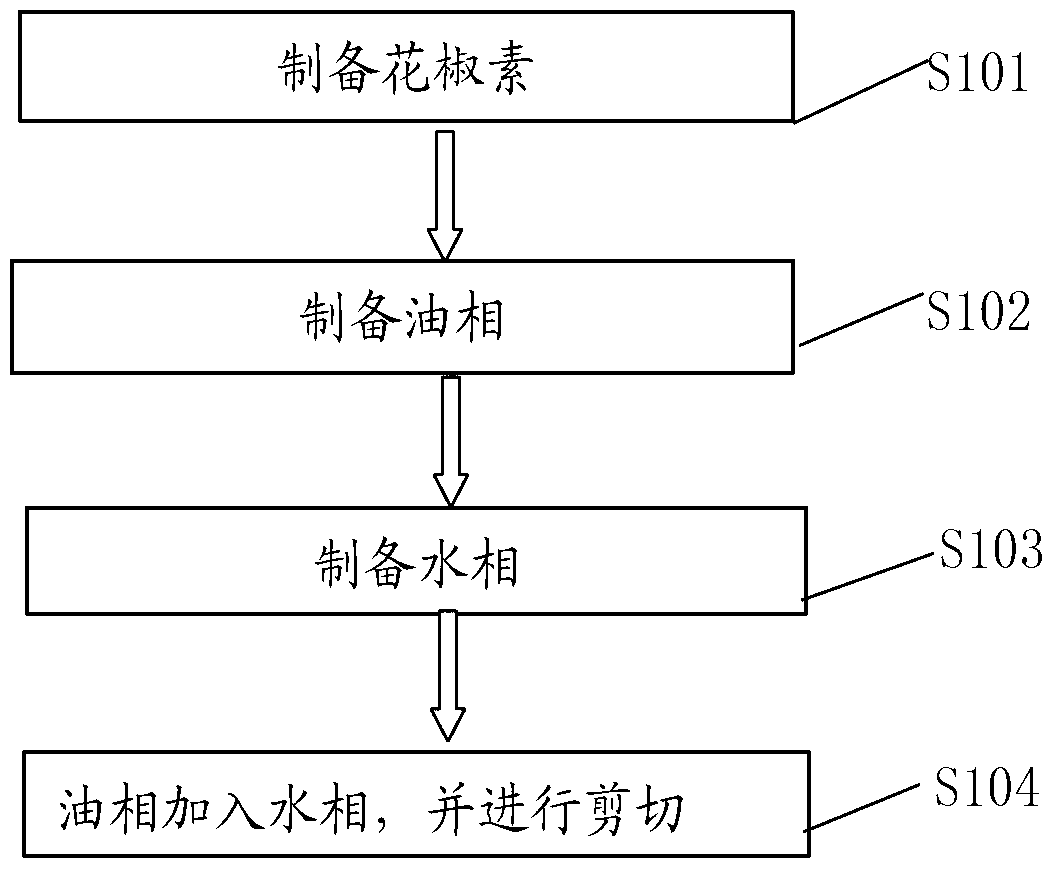

Method used

Image

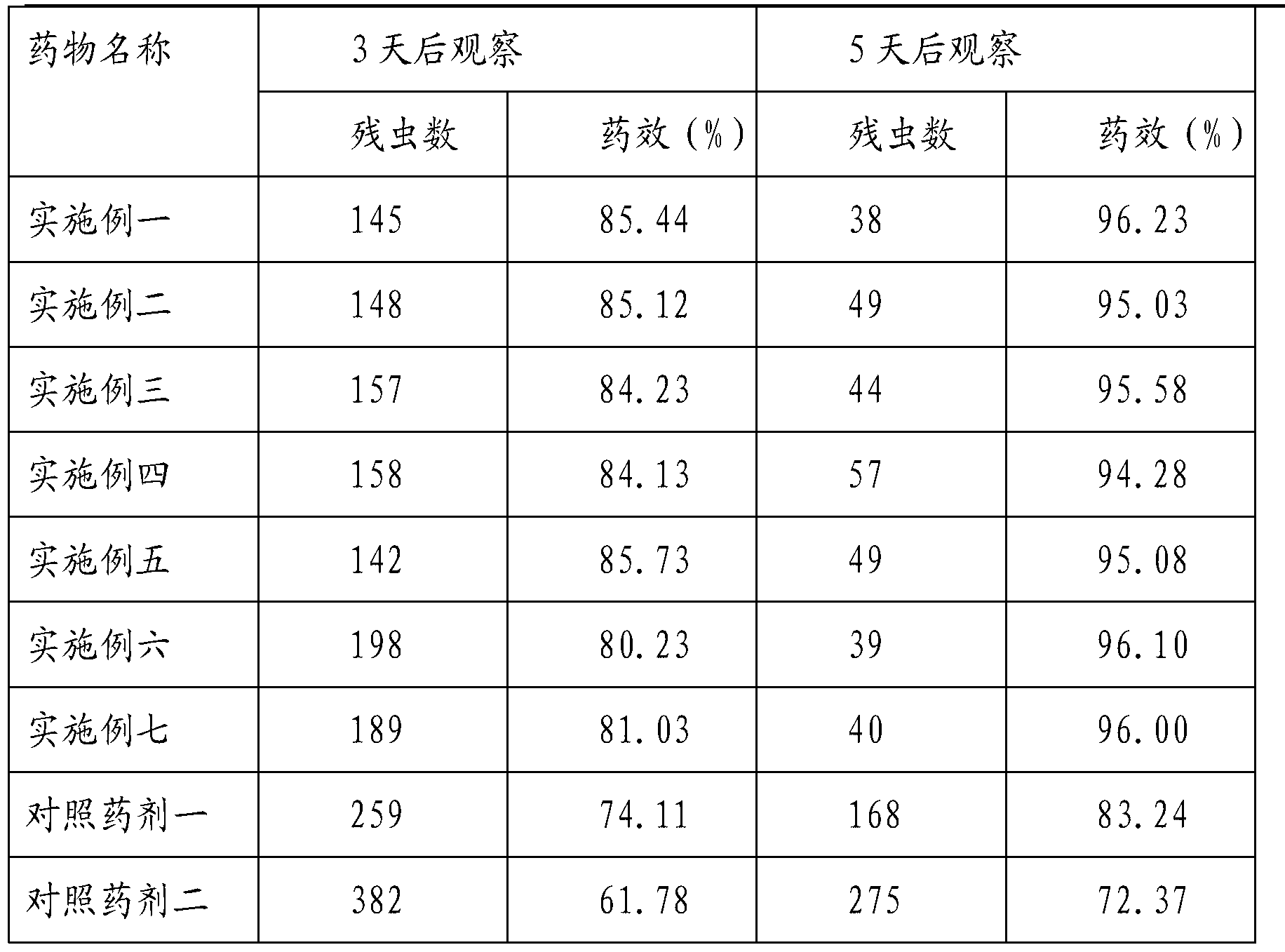

Examples

Embodiment 1

[0036] The Zanthoxylum bungeanum fruit is crushed, the crushed material is processed by a combination of direct steam distillation and pressing, and oil-water separation is carried out on the distilled and squeezed liquid. When separating oil and water, the method of leaving the mixed liquid to stand will make the oil float to the upper layer, and the water will be in the lower layer, then remove the water in the lower layer to obtain the upper layer oil, concentrate the separated pepper oil, cool down and crystallize, and centrifuge to separate the crystals. The recrystallization method is used to purify the crystals to obtain the prickly ash, because the oil obtained by distillation and pressing is only the crude product containing prickly ash, and also contains other vegetable oils. The prickly ash oil contains a part of prickly ash, so it needs to be concentrated and crystallized to extract the prickly ash in the prickly ash oil Xanthoxylin, and then recrystallized and puri...

Embodiment 2

[0039] The Zanthoxylum bungeanum fruit is crushed, and the pulverized material is processed by direct steam distillation and pressing, and the oil and water are separated from the distilled and squeezed liquid, and the separated Zanthoxylum bungeanum oil is concentrated, cooled and crystallized, and the crystals are separated by centrifugation, and the crystals are separated by gravity. Purify the crystalline substance by crystallization to obtain xanthoxylin.

[0040] Put 12.9Kg of xanthoxylin, 100g of avermectin, and 20Kg of soybean oil into a jacketed stirring tank, raise the temperature to 55°C and stir to dissolve for 2 hours, then add 3Kg of thioketone, 2,6-di-tert-butyl- 1Kg of 4-methylphenol and 10Kg of alkylphenol polyoxyethylene ether phosphate were prepared into an oil phase. Add 5Kg of magnesium chloride, 500g of xanthan gum, and 47.5Kg of purified water into another jacketed kettle, raise the temperature to 55°C, stir and mix for 1 hour, and prepare an aqueous pha...

Embodiment 3

[0042] The Zanthoxylum bungeanum fruit is crushed, and the pulverized material is processed by direct steam distillation and pressing, and the oil and water are separated from the distilled and squeezed liquid, and the separated Zanthoxylum bungeanum oil is concentrated, cooled and crystallized, and the crystals are separated by centrifugation, and the crystals are separated by gravity. Purify the crystalline substance by crystallization to obtain xanthoxylin.

[0043] Put 100g of prickly ash, 4.9Kg of abamectin, and 30Kg of turpentine into a jacketed stirring tank, raise the temperature to 55°C and stir to dissolve for 2 hours, then add 3Kg of organic silicon, 1Kg of butyl hydroxyanisole, fatty alcohol poly 13Kg of oxyethylene ether was prepared into an oil phase. Add 5 Kg of urea, 500 g of magnesium aluminum silicate, and 35.5 Kg of distilled water into another jacketed kettle, raise the temperature to 55° C., stir and mix for 1 hour, and prepare an aqueous phase. Finally, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com