Method for manufacturing polymer solar cell mixed with clad nanometer metal

A technology of solar cells and nano-metals, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of limited range of action, exciton quenching, and affecting the electrical properties of batteries, so as to increase light absorption efficiency and avoid exciton quenching The effect of extermination and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

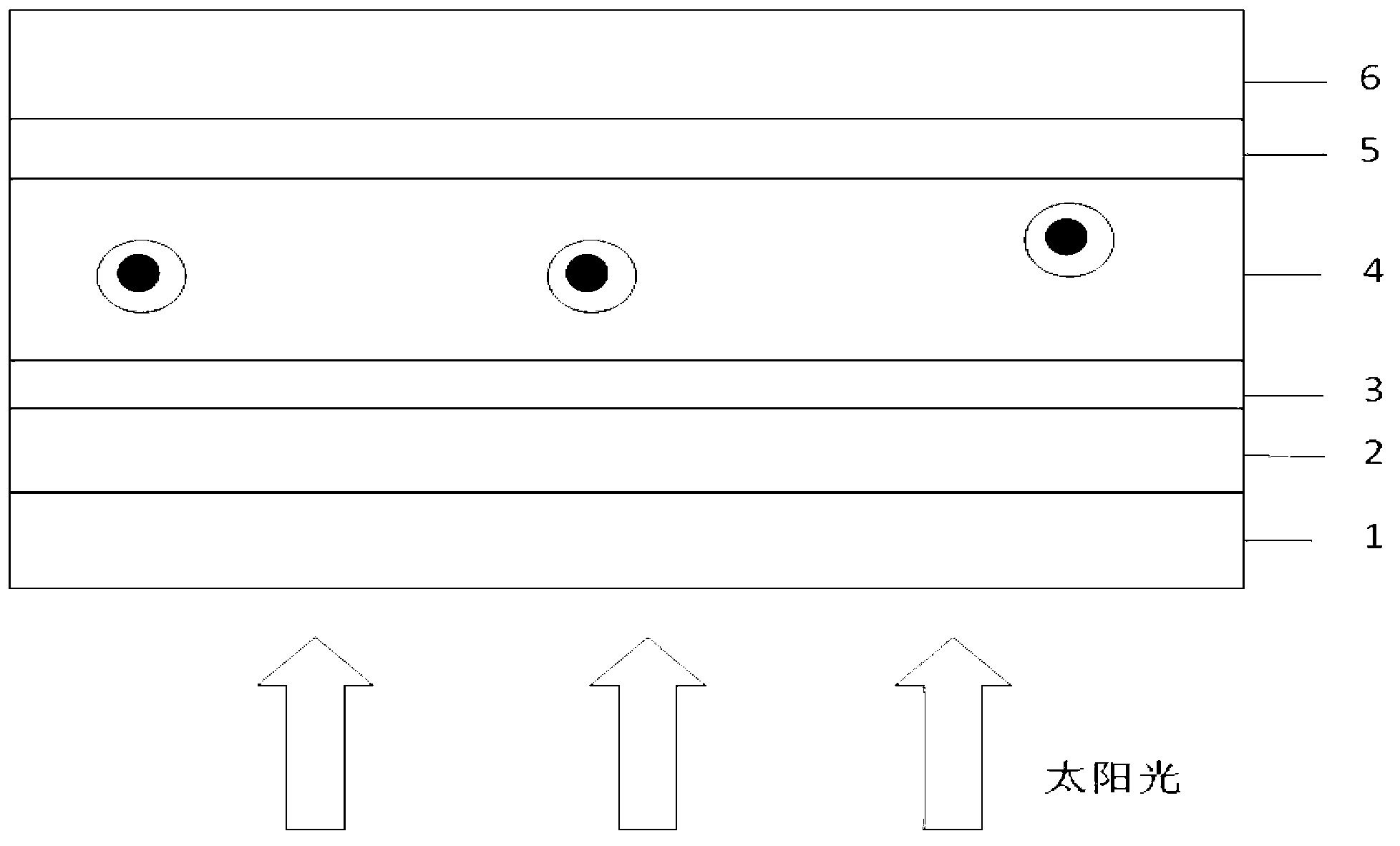

[0027] The main structure of the solar cell prepared in this embodiment includes a glass substrate 1, an anode electrode 2, a hole transport layer 3, a photoactive layer 4, an electron buffer layer 5, and a cathode electrode 6. The anode electrode 2 is an ITO conductive electrode with a thickness of 180 nm. The hole transport layer 3 is a PEDOT:PSS polymer conductive film with a thickness of 30nm; the donor material in the photoactive layer 4 is poly-3-hexylthiophene (P3HT), and the acceptor material is a fullerene derivative (PC 61 BM), the thickness of the photoactive layer is 200nm, and there are also silica-metal core-shell structure nanoparticles with a diameter of about 50nm dispersed in the active layer; the electronic buffer layer is calcium, and the thickness is 10nm; the cathode electrode is aluminum , with a thickness of 100nm.

[0028] The preparation process of the present embodiment comprises the following steps:

[0029] (1) Clean the glass substrate with trans...

Embodiment 2

[0039] The preparation process steps of this embodiment are the same as that of embodiment 1.

[0040] The diameter of the silica-metal core-shell nanoparticle in this example is about 30nm, and the preparation method is as follows: 2ml of silver nitrate aqueous solution with a concentration of 0.01g / ml is added dropwise to 0.295g of polyvinylpyrrolidone (PVP) and In 30ml of glucose aqueous solution, react at 120°C for 30 minutes to obtain Ag nanoparticles with a particle size of about 20nm; after fully ultrasonically dispersing 10ml of Ag sol, mix it with 5ml of ammonia water, 40ml of ethanol and 20ml of distilled water, and add 0.5ml of it dropwise to a concentration of 0.04mol / ml tetraethyl orthosilicate ethanol solution, react at room temperature for 3 hours, centrifuge and wash 3 times after the reaction, and dry at low temperature to obtain silica-silver core-shell structure nanoparticles with a shell size of 5 nm and a particle size of about 30 nm.

Embodiment 3

[0042] The preparation process steps of this embodiment are the same as that of embodiment 1.

[0043] The diameter of the silica-metal core-shell nanoparticle in this example is about 80nm. The preparation method is as follows: add 7ml of silver nitrate aqueous solution with a concentration of 0.01g / ml dropwise to 0.462g of polyvinylpyrrolidone (PVP) and In 30ml of glucose aqueous solution, react at 120°C for 30 minutes to obtain Ag nanoparticles with a particle size of about 50nm; after fully ultrasonically dispersing 10ml of Ag sol, mix it with 5ml of ammonia water, 40ml of ethanol and 20ml of distilled water, and add 2ml of it dropwise to a concentration of 0.04mol / ml tetraethyl orthosilicate ethanol solution, react at room temperature for 5 hours, centrifuge and wash 3 times after the reaction, and dry at low temperature to obtain silica-silver core-shell nanoparticles with a shell of 15 nm and a particle size of about 80 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com