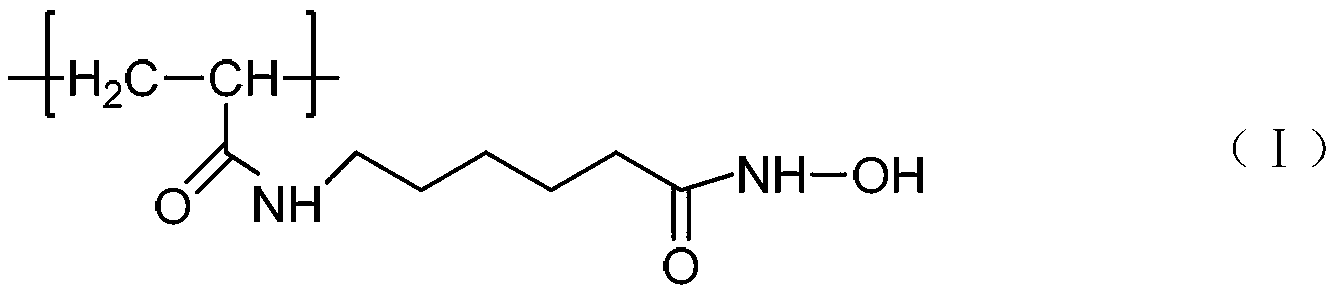

Macromolecule of poly(N-hexyl hydroximic acid acrylamide), and preparation and application methods thereof

A technology of hexylhydroxamic acid acrylamide and an application method, which is applied to the polymer of poly-N-hexylhydroxamic acid acrylamide and its preparation and application fields, can solve the problems that the application of amide group and hydroxime group has not yet been reported, and the like, To achieve the effect of simple preparation process, simple product separation and high reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: Preparation of low molecular weight linear poly N-hexyl hydroxamic acid acrylamide

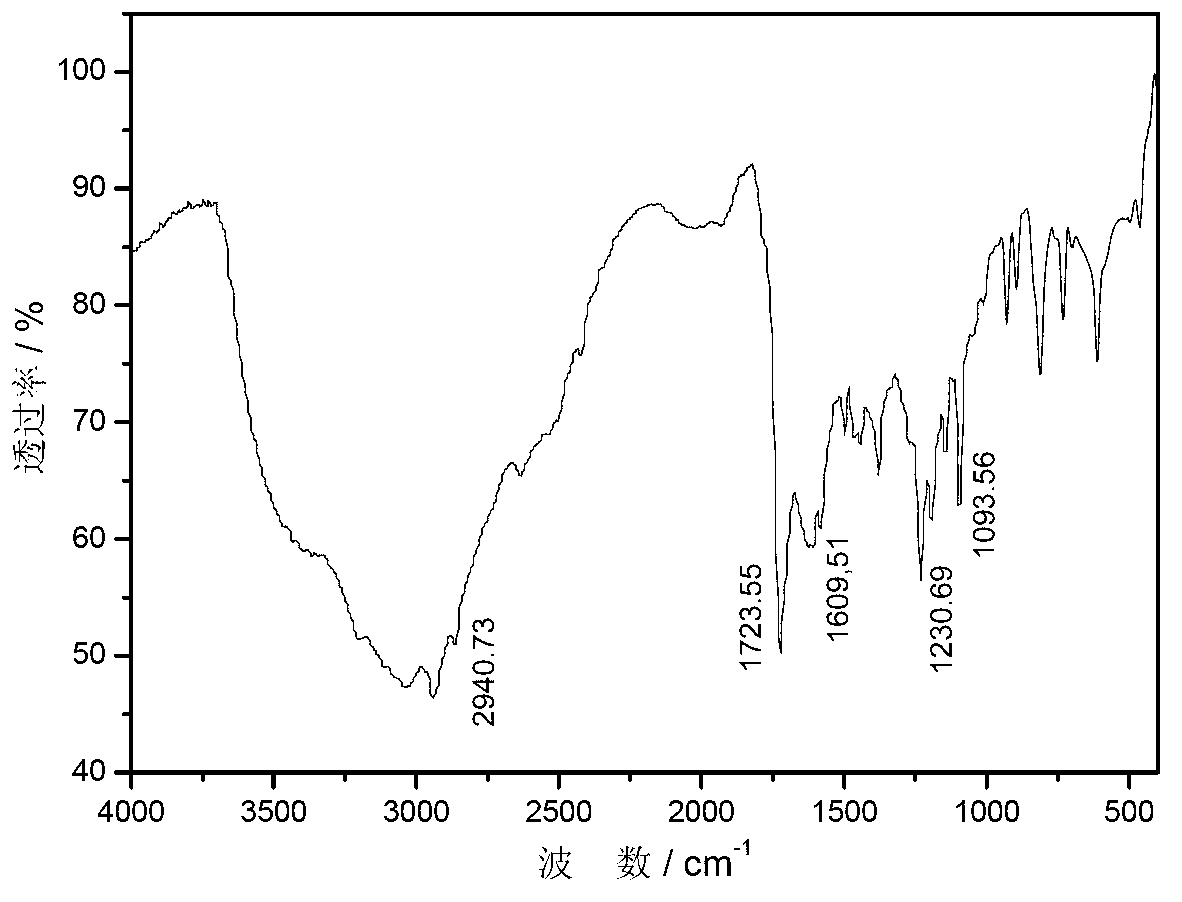

[0026] Add 28 parts of 6-aminohexyl hydroxamic acid and 7.20 parts of polyacrylic acid with an average molecular weight of 3000 into the reactor, heat to 120°C under stirring, react for 3 hours, and filter to obtain linear poly N-hexyl hydroxamic acid acrylamide Solid, the product yield is 98.3%, according to elemental analysis results, the hydroximation rate of polyacrylic acid is calculated to be 98.6%, and its infrared spectrum is shown in figure 1 , 3000~3400cm -1 It is N-H and O-H stretching vibration; 2940cm -1 It is saturated C-H stretching vibration; 1723cm -1 It is C=O stretching vibration, 1609cm -1 is the stretching vibration of the secondary amide.

[0027] Take 100 parts of Fe(III), Cu(II), Ni(II) metal ion solutions with a concentration of 10mmol / L, adjust the pH value to 5.5 with sulfuric acid, and add 0.1 parts of low molecular weight linear poly N-hexy...

Embodiment 2

[0028] Embodiment 2: the preparation of high molecular weight linear poly N-hexyl hydroxamic acid acrylamide

[0029] 28 parts of 6-aminohexyl hydroxamic acid and 7.20 parts of average molecular weight are 2×10 6 Add polyacrylic acid into the reactor, heat to 130°C under stirring, react for 3 hours, and filter to obtain linear poly-N-hexylhydroxamic acid acrylamide solid, the product yield is 99.5%, and the hydroxamation rate is 97.7%.

[0030] Dissolve poly N-hexyl hydroxamic acid acrylamide in sodium hydroxide solution, add it to the red mud slurry with a solid content of 25%, the dosage of poly N-hexyl hydroxamic acid acrylamide is 5mg / L, after 20 minutes, measure The red mud deposition height is 26.2% of the slurry height; the average molecular weight is 2×10 6 Polyacrylic acid is used as flocculant. Under the same conditions as above, the red mud deposition height is measured to be 30.4% of the pulp height, indicating that the flocculation and sedimentation performance o...

Embodiment 3

[0031] Embodiment 3: the preparation of poly N-hexylhydroxamic acid acrylamide resin

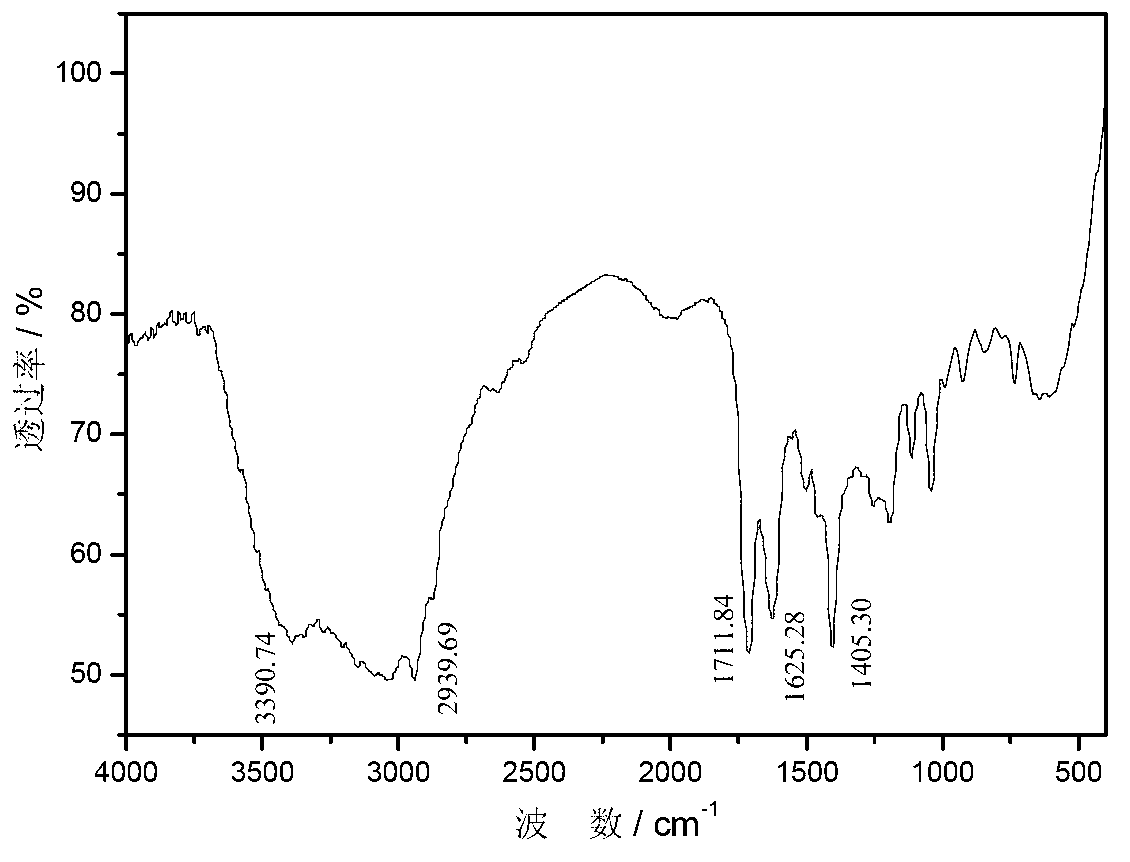

[0032] Add 28 parts of 6-aminohexyl hydroxamic acid and 8.62 parts of macroporous polyacrylic acid resin D113 into the reactor, heat to 150°C under stirring, react for 3 hours, and filter to obtain poly-N-hexyl hydroxamic acid acrylamide resin, The product yield is 97.7%, and the hydroximation rate is 97.2%. Its infrared spectrogram is shown in figure 2 , 3000~3400cm -1 It is N-H and O-H stretching vibration; 2939cm -1 It is saturated C-H stretching vibration; 1711cm -1 It is C=O stretching vibration, 1625cm -1 is the stretching vibration of the secondary amide. According to the literature (Shuai Wang, Gang Zhao, Zhongnan Wang, et al. Applied Mechanics and Materials, 2012, 161: 200-204), polymethacryl hydroxamic acid resin was prepared for adsorption performance comparison.

[0033] Prepare Fe(III), Cu(II), Ni(II), La(III) and Y(III) metal ion solutions with a concentration of 1g / L res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com