Artificial lens with differently modified front and rear ultraviolet irradiation surfaces, and preparation method thereof

A technology of intraocular lens and front and rear surfaces, applied in prosthetics, medical science, etc., can solve the problems of not being able to alleviate the complications related to the front surface, unfavorable for large-scale production, weakening complications, etc., to achieve inhibition of cell adhesion, cell adhesion Improve and reduce the effect of complications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

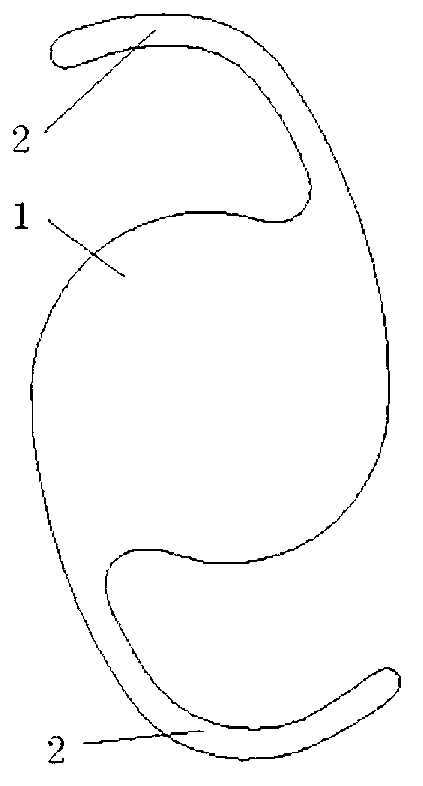

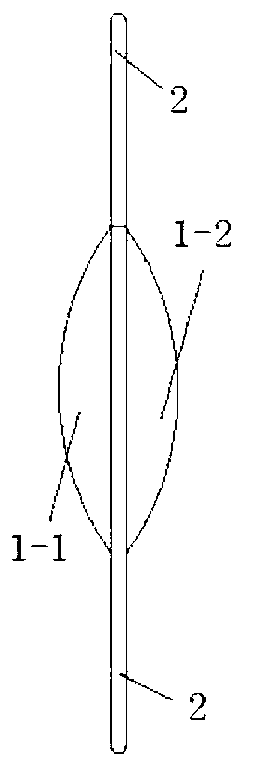

[0027] Before manufacturing the soft intraocular lens with double-surface modification, first select the manufacturing material of the intraocular lens and the modified material on its surface. High pressure sterilization, no biodegradation, so that the intraocular lens is soft, flexible, and can be bent and compressed so that it can be implanted in the eye with a small incision, and the postoperative astigmatism is small and the recovery is fast; in addition, its specific gravity is required to be small, It is not easy to crush the iris, can reduce the rupture of the zonular ligament of the intraocular lens and the subsequent dislocation, and the potential complications caused by contact with the uveal tissue, and its safety and reliability should be recognized in clinical use. According to these requirements, this embodiment uses hydrophobic soft materials, such as silicone gel, hydrophobic acrylate, etc., and takes hydrophobic acrylate as an example to make an intraocular le...

Embodiment 2

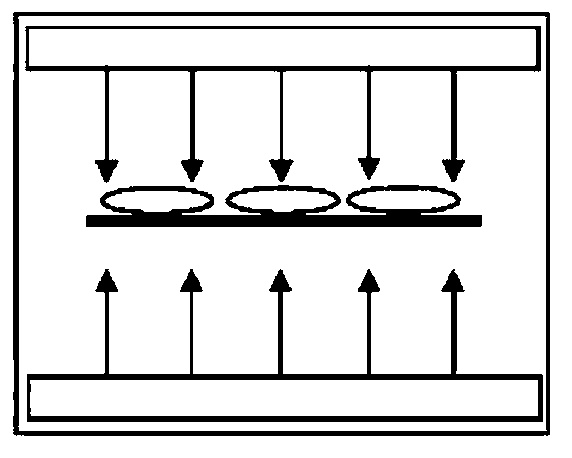

[0039] The manufacturing method of the double-surface-modified soft intraocular lens irradiated with ultraviolet light in this example adopts a different free radical initiation method from Example 1: spraying an ethanol solution of benzophenone (BP) on the front surface of the intraocular lens , after the solvent evaporates, the aqueous solution of the phospholipid monomer is coated on the front surface of the intraocular lens, and the intraocular lens is put into the ultraviolet light generator in Example 1 to accept ultraviolet light irradiation for 1-20min, so that the phospholipid monomer is grafted on the Hydrophobic soft acrylate intraocular lens surface; irradiated and then soaked in triple distilled water for 72 hours to remove unpolymerized phospholipid monomers, and finally vacuum-dried, and sealed and packaged after drying. In the ethanol solution of benzophenone (BP): the volume fraction of benzophenone is 10%.

[0040] After measurement, the modification effect o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com