Graphene composite transparent electrode and preparation method and application thereof

A technology of transparent electrodes and composite materials, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems affecting optoelectronic properties, multiple defects and grain boundaries, etc., to improve electrical conductivity and stability, low cost, excellent The effect of optoelectronic properties and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

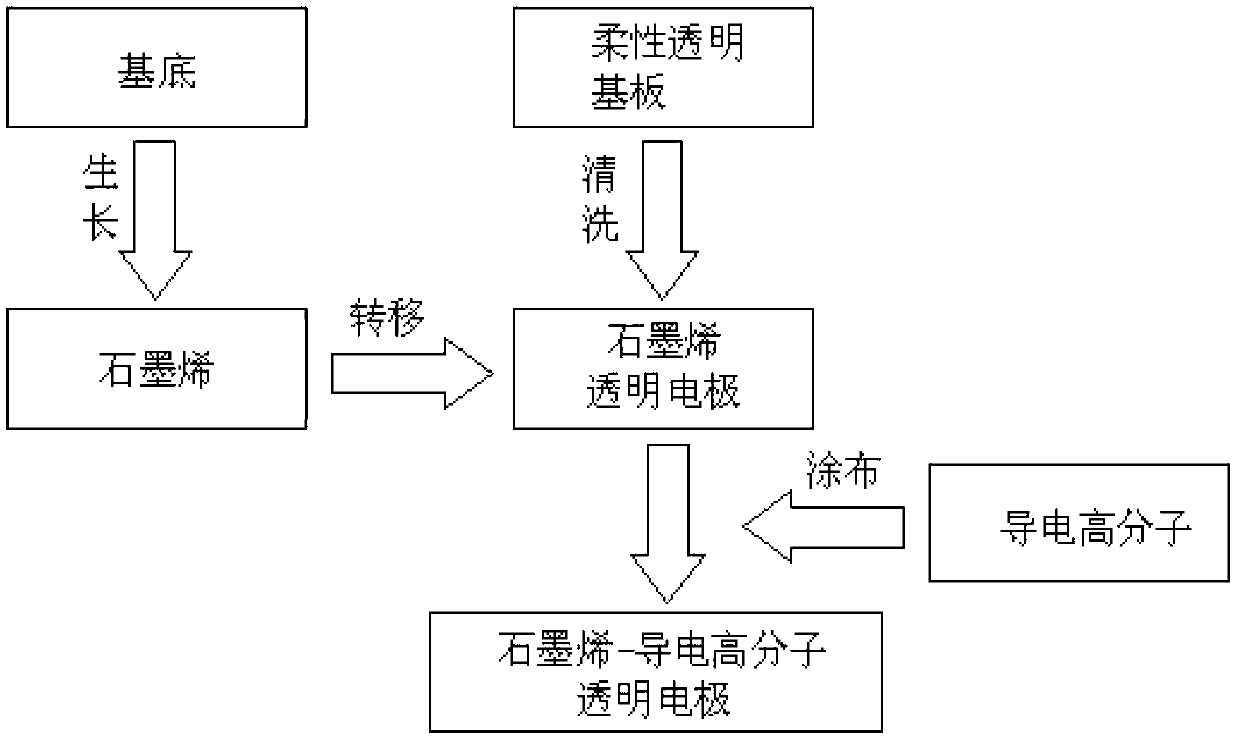

[0046] Such as figure 1 As shown, the preparation method of the graphene composite material transparent electrode of the present embodiment comprises the following steps:

[0047] 1) Using ordinary thermocouple heating chemical vapor deposition method, using copper foil as substrate and catalyst, CH 4 Under the condition of gaseous carbon source, the growth of graphene is carried out, the growth temperature is 800°C, and the growth time is 100min;

[0048] 2) The graphene grown on the substrate was peeled off and transferred to the flexible transparent substrate of polyethylene terephthalate by using the method of thermal release tape-etching;

[0049] 3) Coating conductive polymer material polythiophene (Polythienylene, PT) on the surface of graphene by spraying method to form a conductive polymer layer and obtain a transparent electrode of graphene composite material.

[0050] The structure of the graphene composite transparent electrode prepared in this embodiment is as f...

Embodiment 2

[0054] Such as figure 1 As shown, the preparation method of the graphene composite material transparent electrode of the present embodiment comprises the following steps:

[0055] 1) Using radio frequency plasma assisted chemical vapor deposition method, on nickel foil as substrate and catalyst, C 2 h 4 Under the condition of gaseous carbon source, the growth of graphene is carried out, the growth temperature is 1000°C, and the growth time is 200min;

[0056] 2) The graphene grown on the substrate is peeled off by electrolytic bubbling stripping method, and transferred to a flexible transparent polycarbonate substrate;

[0057] 3) The conductive polymer material polypyrrole (Polypyrol, PPY) is coated on the surface of graphene by spin coating method to form a conductive polymer layer and obtain a transparent electrode of graphene composite material.

[0058] The structure of the graphene composite transparent electrode prepared in this embodiment is as follows Figure 5 As...

Embodiment 3

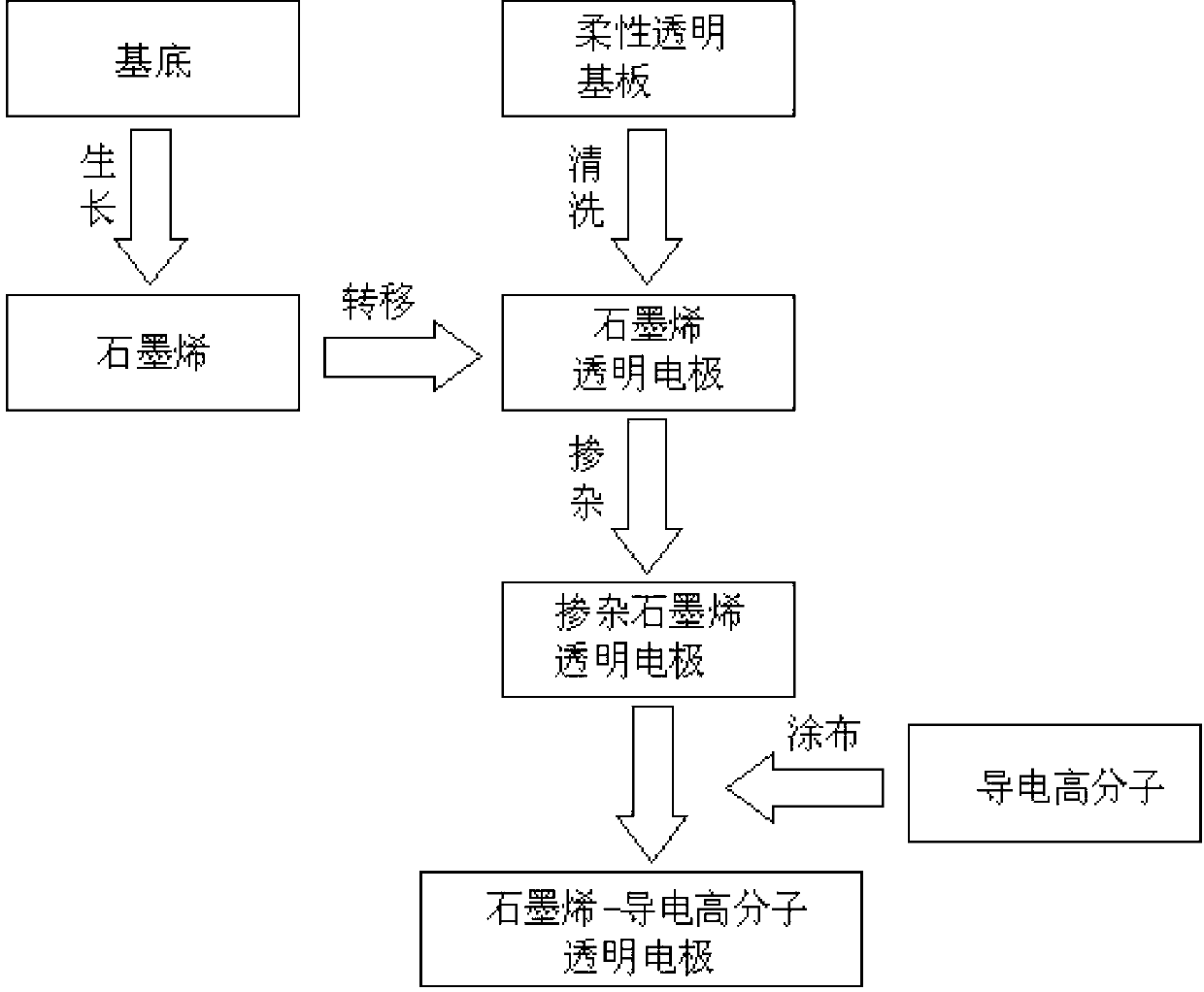

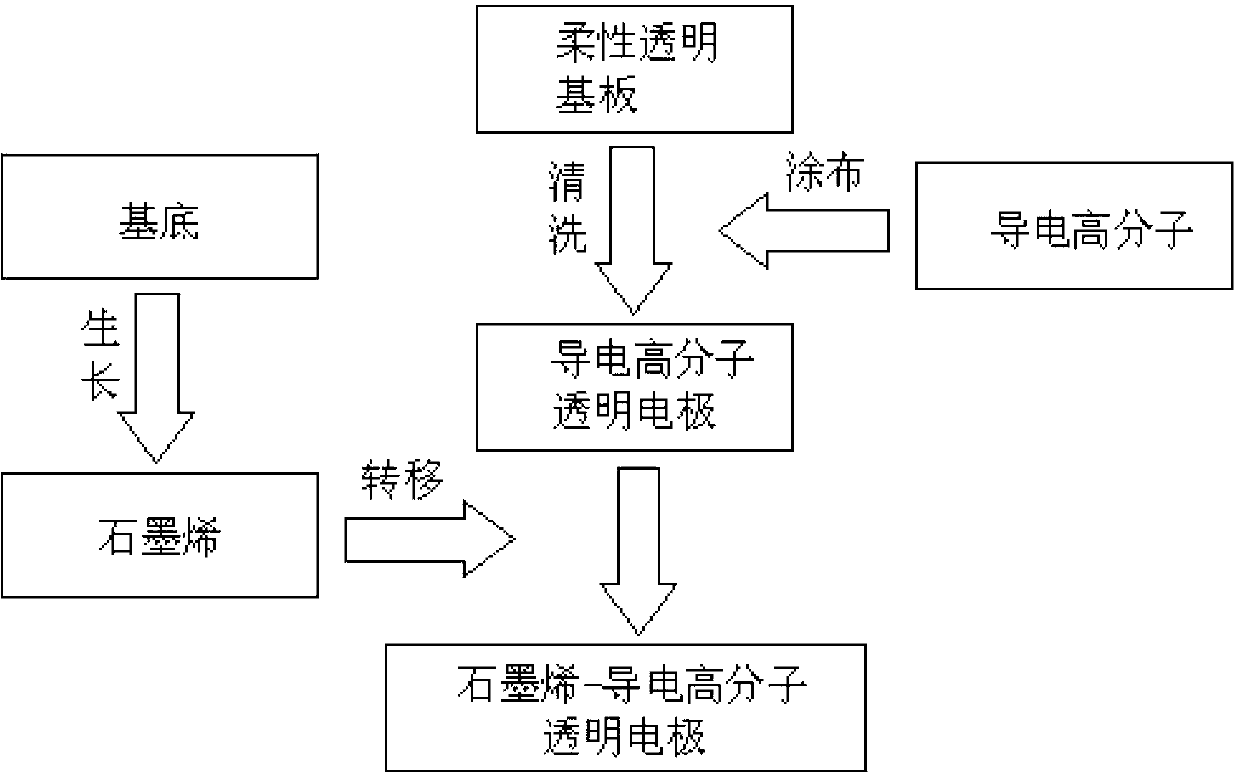

[0061] Such as figure 2 As shown, the preparation method of the graphene composite material transparent electrode of the present embodiment comprises the following steps:

[0062] 1) The remote plasma-assisted chemical vapor deposition method was used to grow graphene under the conditions of gold foil as the substrate and catalyst, and benzene as the liquid carbon source. The growth temperature was 500°C and the growth time was 20 minutes;

[0063] 2) The graphene grown on the substrate is peeled off by UV curing-etching method, and transferred to the flexible transparent substrate of polyethylene; then the graphene is doped, and the doping method is HNO 3 The solution is soaked as a doping reagent;

[0064] 3) The conductive polymer material polyphenylene vinylene (PPV) is coated on the surface of graphene by bar coating method to form a conductive polymer layer and obtain a transparent electrode of graphene composite material.

[0065] The structure of the graphene compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com