Method for enriching leucomalachite green and leucogentian violet in aquatic products

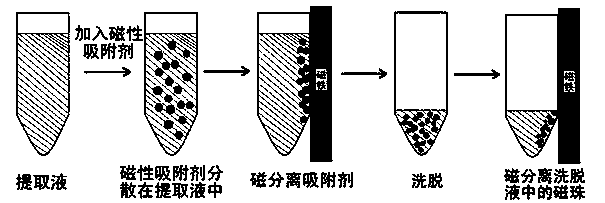

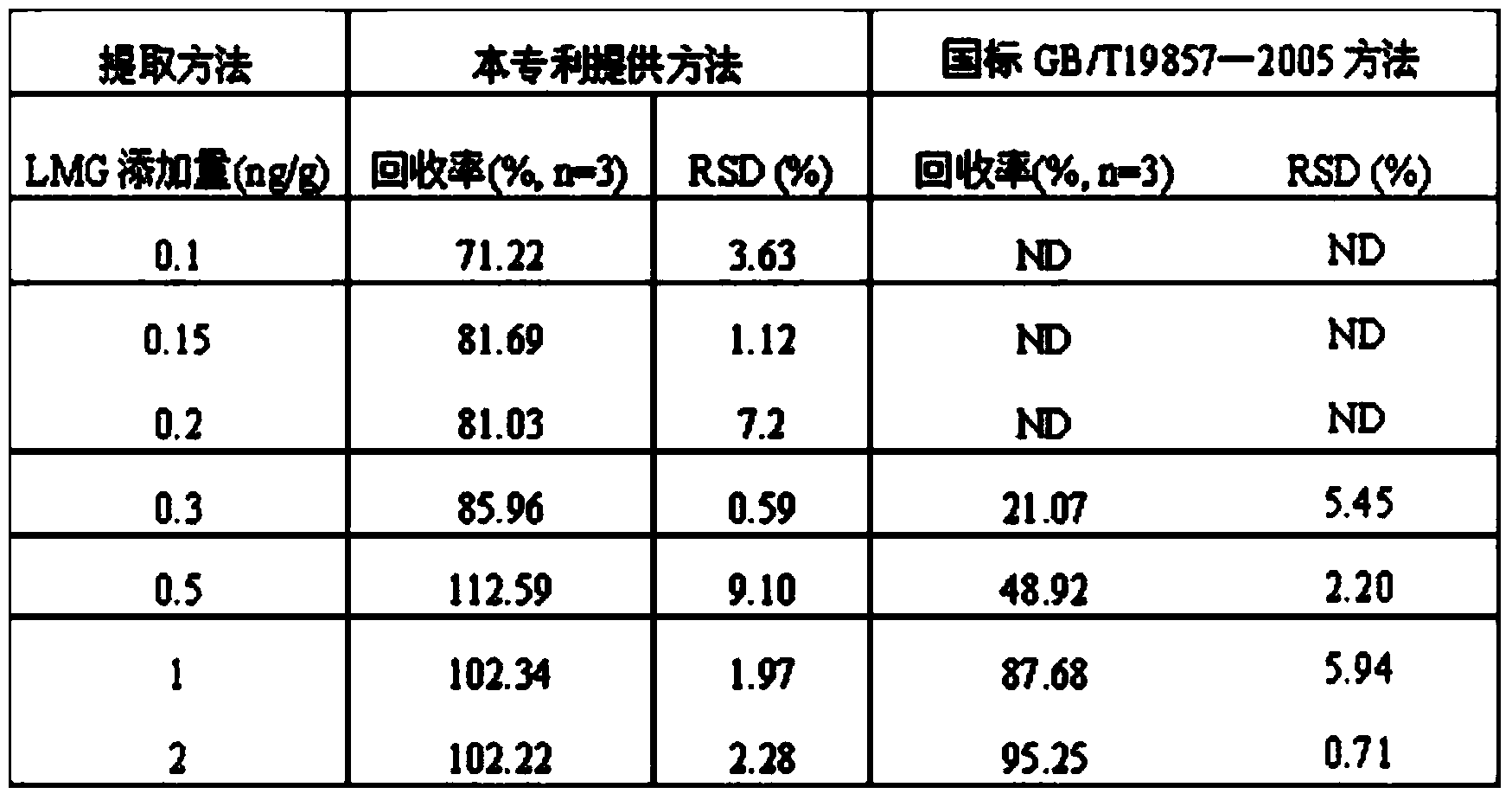

A technology of leuco malachite green and leuco crystal violet is applied in measuring devices, instruments, scientific instruments and other directions, which can solve problems such as workload consumption, save materials, reduce organic solvents, and reduce detection errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

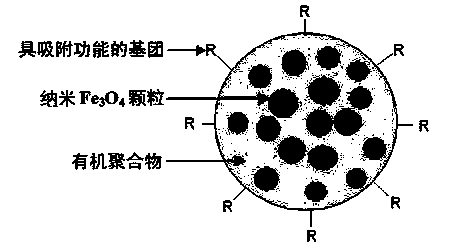

[0043] The C of embodiment 1 particle diameter 100nm 18 Preparation of polystyrene microspheres

[0044] Using surface amino-modified polystyrene magnetic balls as raw materials:

[0045] 1) Amination of carboxylated magnetic spheres: disperse commercialized polystyrene magnetic spheres with a diameter of 100nm and surface carboxyl modification (product of Shanghai Aorun Micro-Nano New Material Technology Co., Ltd., product number PM3-008) in boron In salt buffer solution (pH4.0), according to the molar ratio of carboxyl group: 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide: N-hydroxysulfosuccinimide on the magnetic ball =1:3:6 Add 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide and N-hydroxysulfosuccinimide respectively, and shake for 2 hours to activate the carboxyl group on the magnetic ball. Take ethylenediamine, add a dose of 300 to 800 times the molar number of carboxyl groups, adjust the pH to 8 with concentrated hydrochloric acid, add activated magnetic balls, shake and...

Embodiment 2

[0048] The C of embodiment 2 particle size 180nm 18 Preparation of polystyrene magnetic spheres

[0049] In step (1), commercialized polystyrene magnetic balls with a diameter of 180nm and surface carboxyl modification (product of Shanghai Aorun Micro-Nano New Material Technology Co., Ltd., product number PM3-020) are used as raw materials;

[0050] In step (2), take 700 μL of oleic acid and add it to 3.5 mL of anhydrous tetrahydrofuran, according to the molar ratio of oleic acid:N,N-dicyclohexylcarbodiimide:N-hydroxysuccinimide=1:3:6 respectively Add N,N-dicyclohexylcarbodiimide and N-hydroxysuccinimide, shake vigorously for 2 hours, centrifuge to get the supernatant, add triethylamine to adjust the pH value of the solution to 9;

[0051] In step (3), 500 mg of polystyrene magnetic spheres with a particle size of 180 nm and modified by surface amino groups in step (1) were washed twice with anhydrous tetrahydrofuran in advance, and then added to oleic acid with activated car...

Embodiment 3

[0053] The C of embodiment 3 particle diameter 70nm 18 Preparation of silica magnetic spheres

[0054] Using a magnetic ball with a silica shell as a carrier:

[0055] 1) Synthesis of silica magnetic spheres with a particle size of 70nm. Referring to the literature (Yan F, Li J, Zhang J, Liu F, Yang W.J.Nanopart.Res., 2009, 11(2):289~296), the chemical co-precipitation method was used to synthesize superparamagnetic Fe 3 o 4 single nanoparticle. Fe 3 o 4 The surface of nanoparticles was acidified with oil, washed with absolute ethanol and dried with nitrogen gas. Suspend 3g Fe in 2.0mL cyclohexane 3 o 4 Nanoparticles to obtain ferrofluid, transfer the ferrofluid into 400mL, 0.01M NaHCO containing 0.5% SDS 3 In the solution, 300W (25KHz) power continued ultrasonic emulsification for 30min to form a fine emulsion; reflux at 70°C for 12h to remove cyclohexane to obtain Fe 3 o 4 Nanoparticle clusters; Magnetic separation of Fe 3 o 4 Nanoparticle clusters, suspended Fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com