Metal composite material capable of inducing bone growth and application thereof

A metal composite material and bone growth technology, which can be used in medical science, prosthesis, etc., can solve the problem of low biological activity, and achieve the effect of high biological activity, good mechanical properties, and good biological fixation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

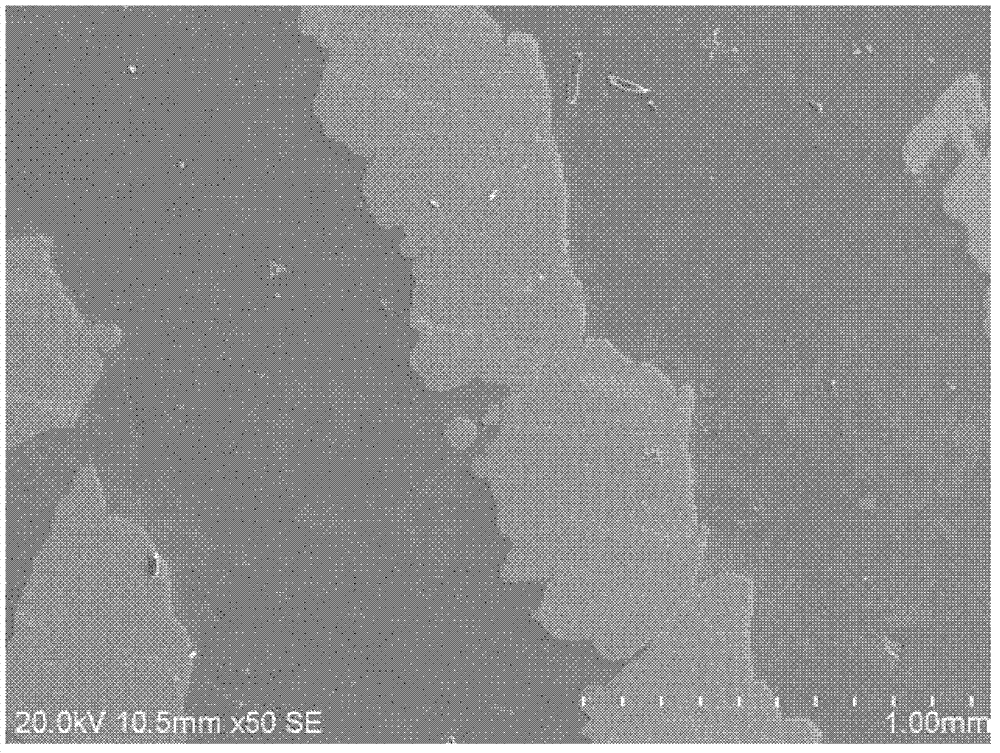

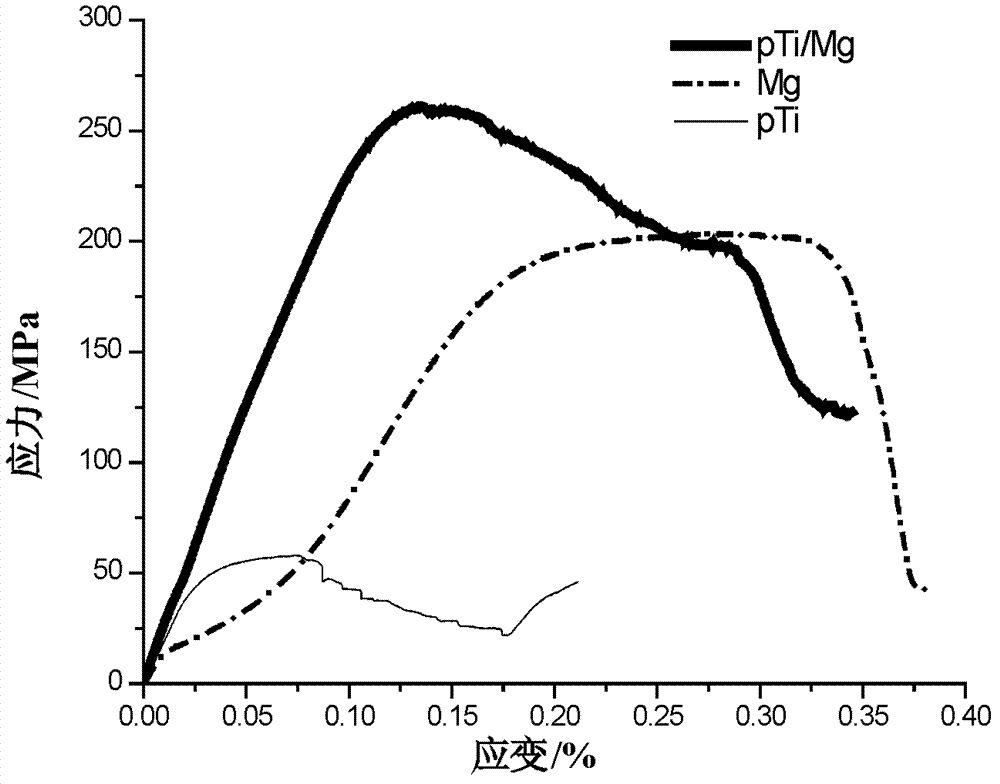

[0023] Using electron beam melting rapid prototyping technology to prepare the size of Cylindrical porous titanium alloy (Ti6Al4V) scaffold, whose morphology is as follows figure 1 shown. The average pore diameter of the above-mentioned scaffold is 600 μm, and the porosity is about 60%. The bracket has a honeycomb-like structure, and the holes communicate with each other and penetrate through the outer surface of the bracket, and have three-dimensional connectivity. Then, pure magnesium (purity: 99.99%) is filled into the pores of the above-mentioned porous titanium alloy bracket by an infiltration method to form a dual-phase composite material. figure 2 That is, the microscopic morphology of the interface of the formed dual-phase composite material. It can be seen that the interface between pure magnesium and the porous titanium alloy scaffold has no defects such as voids, and the pure magnesium is completely filled in the three-dimensional pores of the porous titanium al...

Embodiment 2

[0027] Porous 317L stainless steel samples with porosities of 58% and 70% were obtained by slurry foaming method. The porous stainless steel has a three-dimensional network structure with strong penetration and uniform pore distribution. The pore diameter is 40-250 μm, and the compressive strength is respectively 189MPa and 59MPa. The Mg-0.5Ca alloy is filled into the porous stainless steel samples with two porosities mentioned above to form a two-phase composite material with two pore structures by means of melt infiltration. The compressive strengths of these two composite materials increased from 189MPa and 59MPa of porous stainless steel to 380MPa and 283MPa, respectively. It can be seen that the filling of Mg-Ca alloy is beneficial to the improvement of the mechanical properties of porous materials. After the above-mentioned composite material was cultured in simulated body fluid for 5 days, calcium phosphate was found deposited on the surface, showing good biological act...

Embodiment 3

[0029] The size is prepared by laser drilling technology: 5×5×5mm 3 , a cobalt-based alloy (Co62Cr28Mo6) with a porosity of 75% and a pore diameter of 400-600 μm, and then using an infiltration method to fill the pores of the porous cobalt-based alloy with Mg-6Zn alloy to form a composite material. The compressive strength of the composite material is 232±5MPa, which is greater than the natural bone strength of the human body, and can also meet the mechanical performance requirements of the implant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com