Ytterbium, lutecium, gadolinium and gallium doped garnet laser crystal, preparation method and applications thereof

A technology of ytterbium lutetium gadolinium gallium and laser crystals, applied in ytterbium lutetium gadolinium gallium garnet laser crystals, new laser crystals and their growth and application fields, which can solve the problem of poor crystal optical uniformity, affecting the quality of laser beams, and unstable growth interfaces and other issues, to achieve the effects of long upper energy level lifetime, excellent thermal and spectral performance, and high quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

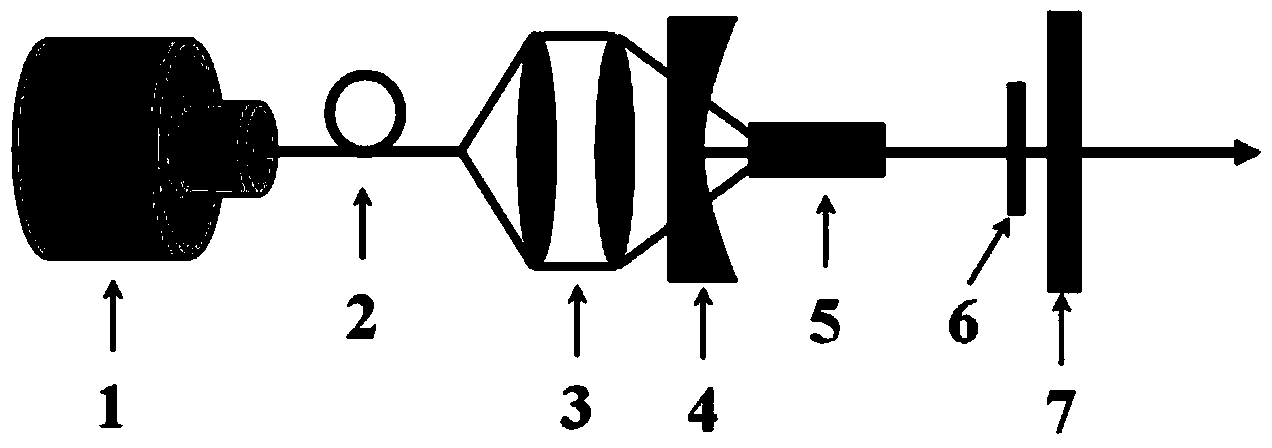

Method used

Image

Examples

Embodiment 1

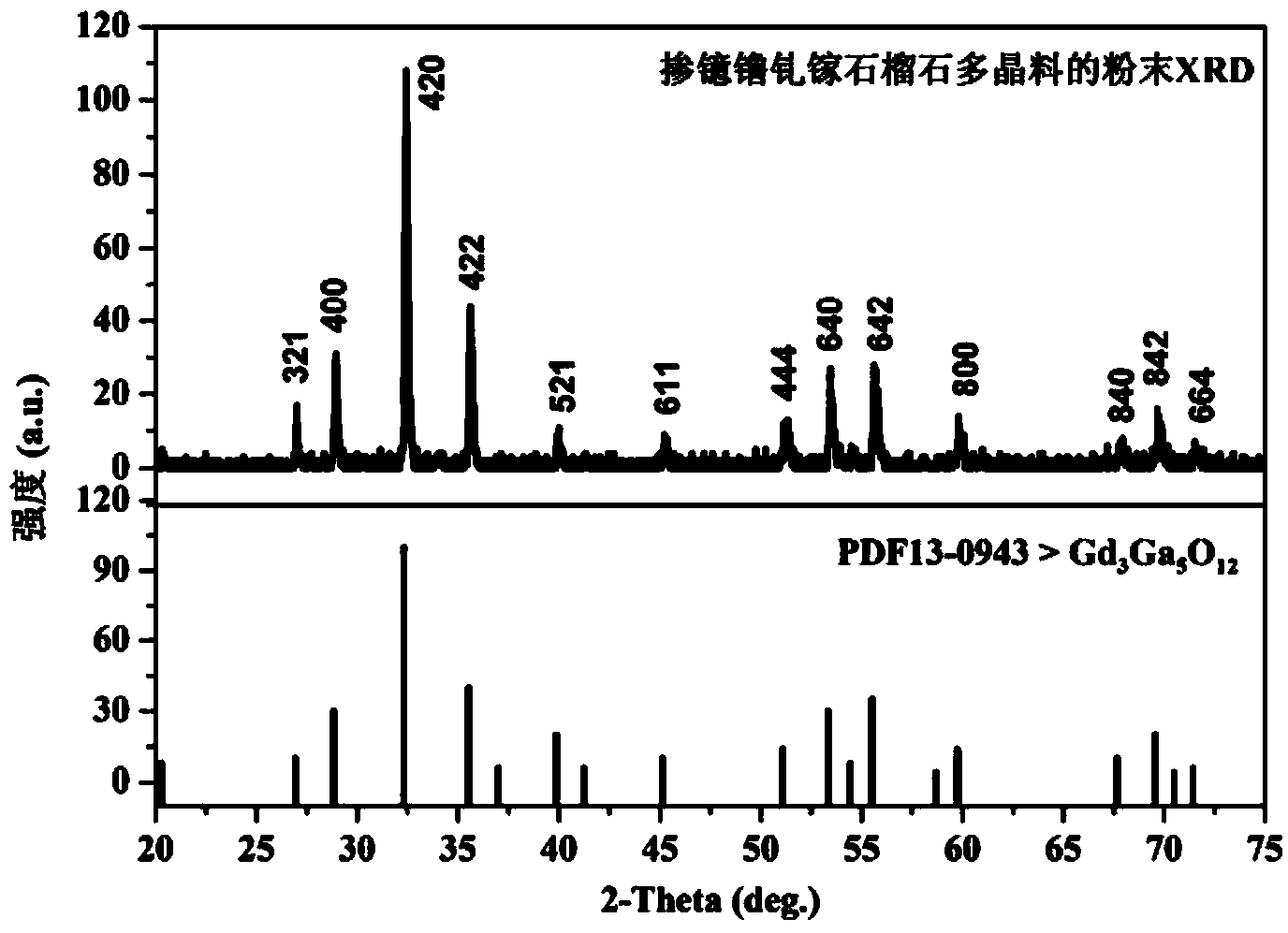

[0042] Example 1: x=0.05, y=0.05, ytterbium-doped lutetium-gadolinium-gallium garnet crystal chemical formula is Yb 0.15 Lu 0.15 Gd 2.7 Ga 5 o 12

[0043] The preparation method of doped ytterbium lutetium gadolinium gallium garnet crystal is as follows:

[0044] (1) Synthesis of polycrystalline material by solid phase sintering method

[0045] The initial raw material is Yb 2 o 3 、Lu 2 o 3 、Gd 2 o 3 and Ga 2 o 3 , with a purity of 99.99%. The chemical reaction equation is as follows:

[0046] 0.15Yb 2 o 3 +0.15Lu 2 o 3 +2.7Gd 2 o 3 +5Ga 2 o 3 =2Yb 0.15 Lu 0.15 Gd 2.7 Ga 5 o 12

[0047] According to Yb 0.15 Lu 0.15 Gd 2.7 Ga 5 o 12 The stoichiometric ratio weighs the corresponding raw material Yb 2 o 3 、Lu 2 o 3 、Gd 2 o 3 and Ga 2 o 3 , considering the presence of Ga during crystal growth 2 o 3 The volatilization and decomposition of Ga 2 o 3 Excess 2wt.% (Ga calculated by stoichiometric ratio 2 o 3 mass meter). Then put into the...

Embodiment 2

[0052] Example 2: x=0.05, y=0.15, ytterbium-doped lutetium-gadolinium-gallium garnet crystal chemical formula is Yb 0.45 Lu 0.15 Gd 2.4 Ga 5 o 12

[0053] According to Yb 0.45 Lu 0.15 Gd 2.4 Ga 5 o 12 The stoichiometric ratio weighs the corresponding raw material Yb 2 o 3 、Lu 2 o 3 、Gd 2 o 3 and Ga 2 o 3 , and make Ga 2 o 3 Excess 3wt.% (Ga calculated by stoichiometric ratio 2 o 3 mass meter), then fully mixed, and the mixing time was 50 hours. Use a hydraulic press to press the raw material into a cylindrical block, put it into a corundum crucible, and use a sintering furnace to calcinate at 1350 ° C for 30 hours to obtain the ytterbium-doped lutetium-gadolinium-gallium garnet polycrystalline material.

[0054] (2) Crystal growth

[0055] As described in step (2) in Example 1, the difference is: during the crystal growth process, the pulling speed is reduced to: 0.5mm / hour; after the crystal growth is completed and stripped, the cooling rate is 40°C / hour...

Embodiment 3

[0057] As described in Example 1, the difference is that the liquid phase method is used to synthesize the polycrystalline material

[0058] Raw material Yb 2 o 3 、Lu 2 o 3 、Gd 2 o 3 and Ga 2 o 3 React with concentrated nitric acid (mass fraction about 65%), and add hydrochloric acid (mass fraction about 35%) of 10% of the total mass of raw materials to promote the reaction process, and obtain Yb(NO 3 ) 3 , Lu(NO 3 ) 3 , Gd(NO 3 ) 3 and Ga(NO 3 ) 3 Four nitrate mixed solutions, then adjust the pH value of the mixed solution to 4.5 with ammonia water, then slowly add 2mol L -1 ammonium bicarbonate solution until no bubbles are generated in the solution, at which point the pH=7. The obtained precipitate was centrifuged out by a centrifuge, then washed with distilled water and centrifuged again, and the operation was repeated twice. Then the precipitate is dried in a drying oven, pressed into thin sheets by a press and calcined at 800°C for 10 hours to obtain a po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com