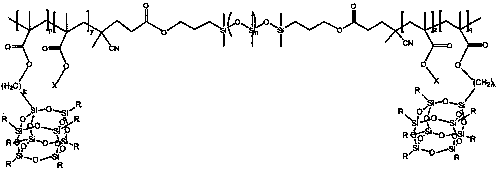

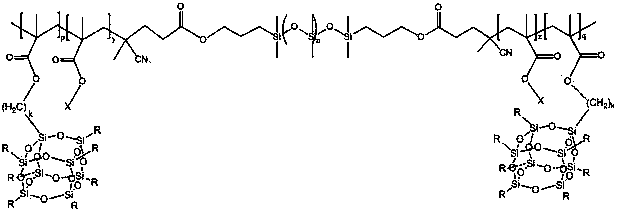

POSS (Polyhedral Oligomeric Silsesquioxane) fluorine-silicon acrylate block copolymer as well as preparation method and application thereof

A technology of siloxane fluorosilicone acrylate and block copolymer, which is applied in the direction of coating, etc., to achieve the effect of easy-to-obtain raw materials, mild experimental conditions, and good blood compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

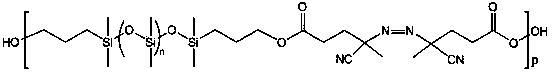

Method used

Image

Examples

Embodiment 1

[0025]Take 10 g of hydrogen-terminated silicone oil (H-PDMS-H) with a number average molecular weight of 10,000, 0.12 g of allyl alcohol, and 50 μl of platinum vinyl siloxane chelate, add 10 g of isopropanol, and react at room temperature for 15 minutes. Take 10g of synthesized HO-PDMS-OH, 0.28g of ACVA, 0.12g of DPTS and add it to the mixed solvent of 50g of dichloromethane and 12g of DMF. After completely dissolving, take 0.83g of DCC and dissolve it in 10g of dichloromethane in the mixed system. After stirring and reacting at room temperature for 24 h, the mixed liquid was added dropwise into a large amount of methanol for precipitation to obtain a polydimethylsiloxane macroinitiator (PDMS-MAI).

[0026] Take 3.5g of PDMS-MAI prepared by the above process, dissolve it in 40g of benzene solvent, stir for half an hour under the protection of nitrogen until it is completely dissolved, raise the temperature of the system to 65°C, and after the temperature is stable, add 2.7g of...

Embodiment 2

[0028] Take 10 g of double-ended hydrogen silicone oil (H-PDMS-H) with a number average molecular weight of 5000 g / mol, 0.23 g of allyl alcohol, and 100 μl of platinum vinyl siloxane chelate, add 10 g of isopropanol, and react at room temperature for 30 min. Take 10g of synthesized HO-PDMS-OH, 0.56g of ACVA, 0.235g of DPTS and add it to the mixed solvent of 50g of dichloromethane and 15g of DMF. After completely dissolving, take 1.65g of DCC and dissolve it in 10g of dichloromethane in the mixed system. After stirring at room temperature for 24 h, the mixture was added dropwise into a large amount of methanol for precipitation. A polydimethylsiloxane macroinitiator (PDMS-MAI) was obtained.

[0029] Take 3g of PDMS-MAI prepared by the above process, dissolve it in 40g of benzene solvent, stir for half an hour under the protection of nitrogen until it is completely dissolved, raise the temperature of the system to 65°C, and after the temperature is stable, add 2.5g of methacryl...

Embodiment 3

[0031] Take 10 g of double-ended hydrogen silicone oil (H-PDMS-H) with a number average molecular weight of 2000 g / mol, 0.72 g of allyl alcohol, and 200 μl of platinum vinyl siloxane chelate, add 10 g of isopropanol, and react at room temperature for 60 min. Take 10g of synthesized HO-PDMS-OH, 1.15g of ACVA, 0.5g of DPTS and add it to the mixed solvent of 50g of dichloromethane and 10g of DMF. After completely dissolving, take 3.1g of DCC and dissolve it in 10g of dichloromethane in the mixed system. After stirring at room temperature for 24 h, the mixture was added dropwise into a large amount of methanol for precipitation. A polydimethylsiloxane macroinitiator (PDMS-MAI) was obtained.

[0032] Take 3g of PDMS-MAI prepared by the above process, dissolve it in 40g of benzene solvent, stir for half an hour under the protection of nitrogen until it is completely dissolved, raise the temperature of the system to 65°C, and after the temperature is stable, add 3g of methyl methacr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com