Novel preparation method for ternary alloy type CdSeS quantum dots

A ternary alloy and quantum dot technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as low cost, poor reproducibility, and no strong reducibility, and achieve stable product properties, low cost, and stable optical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

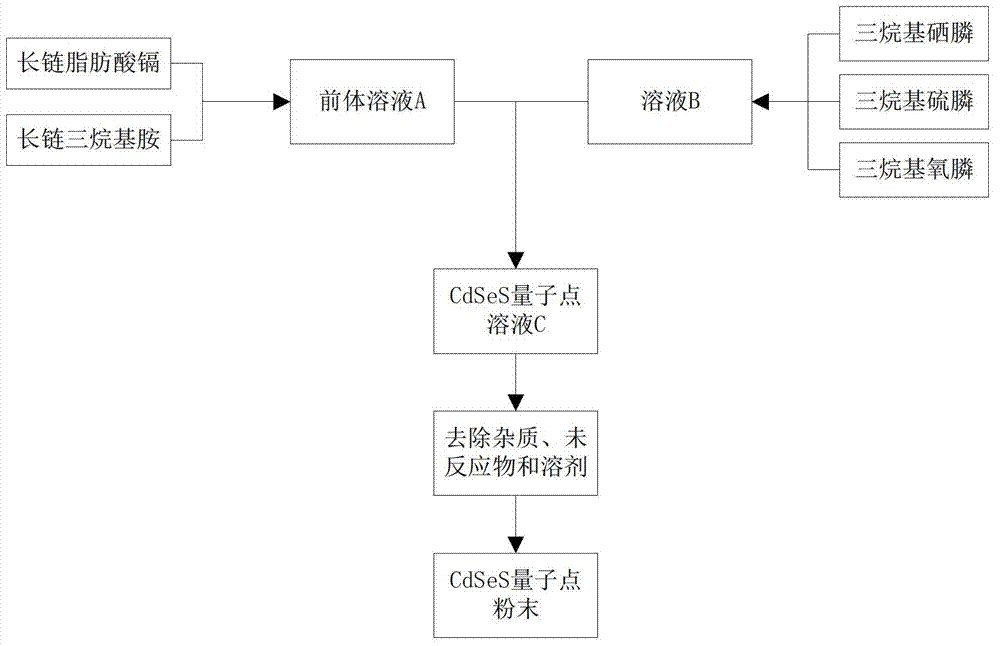

[0029] The invention provides a new preparation method of ternary alloy type CdSeS quantum dots, comprising the following steps:

[0030] a. Install mechanical stirring and inert gas protection device on the four-necked bottle, heat the long-chain fatty acid cadmium and long-chain trialkylamine to 250-350°C under the protection of inert gas to obtain precursor solution A;

[0031] The long-chain fatty acid cadmium is the cadmium source of the target CdSeS quantum dot, the type of the long-chain fatty acid cadmium is not limited, and the preferred divalent cadmium compound is cadmium myristate, cadmium palmitate, cadmium stearate or cadmium oleate , more preferably cadmium oleate and cadmium stearate.

[0032] Compared with the preparation method of the prior art, inorganic cadmium compounds are used, such as cadmium oxide, cadmium chloride, cadmium sulfate, cadmium carbonate, etc., all produce water or inorganic acid during high temperature reaction-these by-products are very ...

Embodiment 1

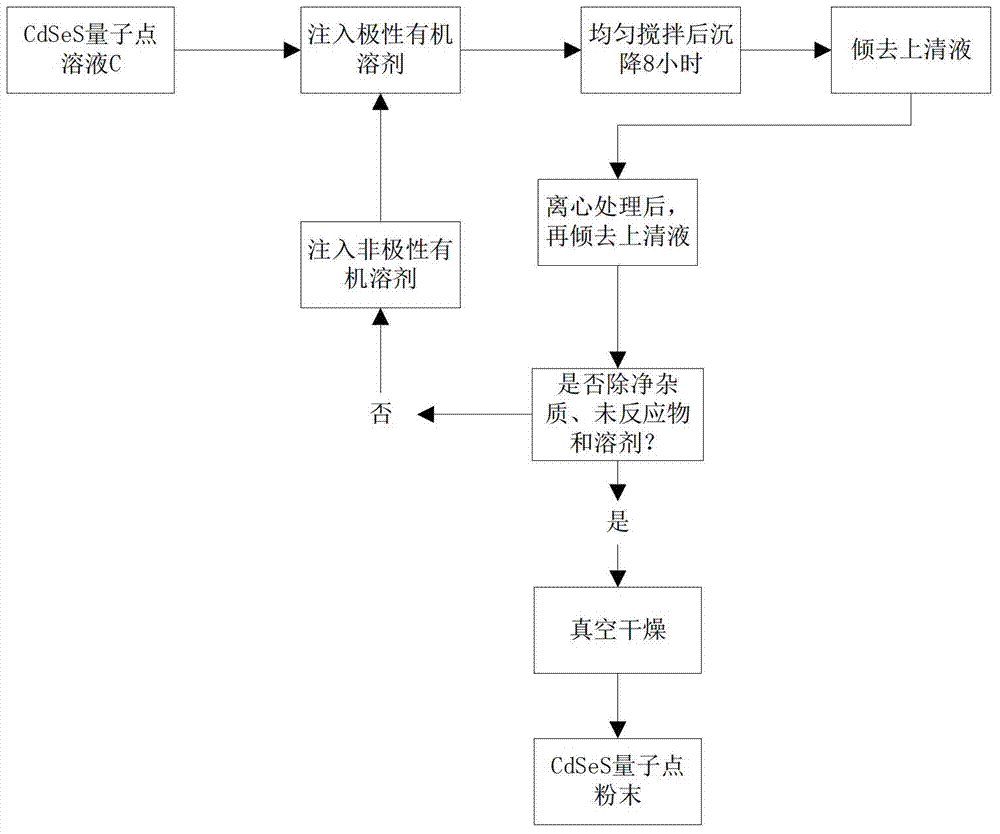

[0047] Install mechanical stirring and argon protection device on the 500ml four-necked bottle, add 12.157 grams (20.3 mmol) cadmium stearate (CdSt 2 ), 20ml oleic acid (OA) and 200ml trioctylamine (TOA), heated up under the protection of argon. Accurately weigh 0.746 g (1.66 mmol) of trioctylselenophosphine (TOPSe), 28.189 g (70 mmol) of trioctylsulfophosphine (TOPS) and 9.918 g of trioctylphosphine oxide (TOPO, stock solution) in a 50 ml beaker, Mix well and draw into a 50ml syringe. When the reaction temperature reaches 295°C and is stable, a light brown transparent liquid is obtained. Inject the stock solution within 5 seconds and maintain the temperature for 5 minutes. Transfer the reaction solution to a triangular flask filled with ethanol, let it stand for more than 8 hours, pour off the supernatant, centrifuge, and pour off the supernatant; add a small amount of chloroform to dissolve the remaining solid, and then add ethanol. Repeat operation. The remaining solid ...

Embodiment 2

[0050] Install mechanical stirring and argon protection device on the 100ml four-necked bottle, add 1197.76mg (2mmol) CdSt 2 , 2mlOA and 30mlTOA, heated up under the protection of argon. Accurately weigh 0.180gTOPSe, 1.208gTOPS and 2mlTOPO (stock solution) in a 10ml beaker, mix well, and draw into a 5ml syringe. When the reaction temperature reaches 310°C and is stable, a light brown transparent liquid is obtained. Inject the stock solution within 5 seconds and maintain the temperature for 5 minutes. Transfer the reaction solution to a triangular flask filled with ethanol, let it stand for more than 8 hours, pour off the supernatant, centrifuge, and pour off the supernatant; add a small amount of chloroform to dissolve the remaining solid, and then add ethanol. Repeat operation. The remaining solid was vacuum-dried for 2 hours to obtain 0.219 g of cadmium sulfur selenide quantum dot solid powder.

[0051] Measured on the A380 fluorescence spectrophotometer produced in Gang...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com