Method for efficiently enriching rare precious metals from complex low-grade heat filter residues

A low-grade heat, rare and precious metal technology, applied in the improvement of process efficiency, thiosulfate/dithionite/polythionite, etc., can solve the dispersion loss of rare and precious metals, large material turnover, valuable Metal flying and other problems, to achieve the effect of good comprehensive utilization, high enrichment ratio and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

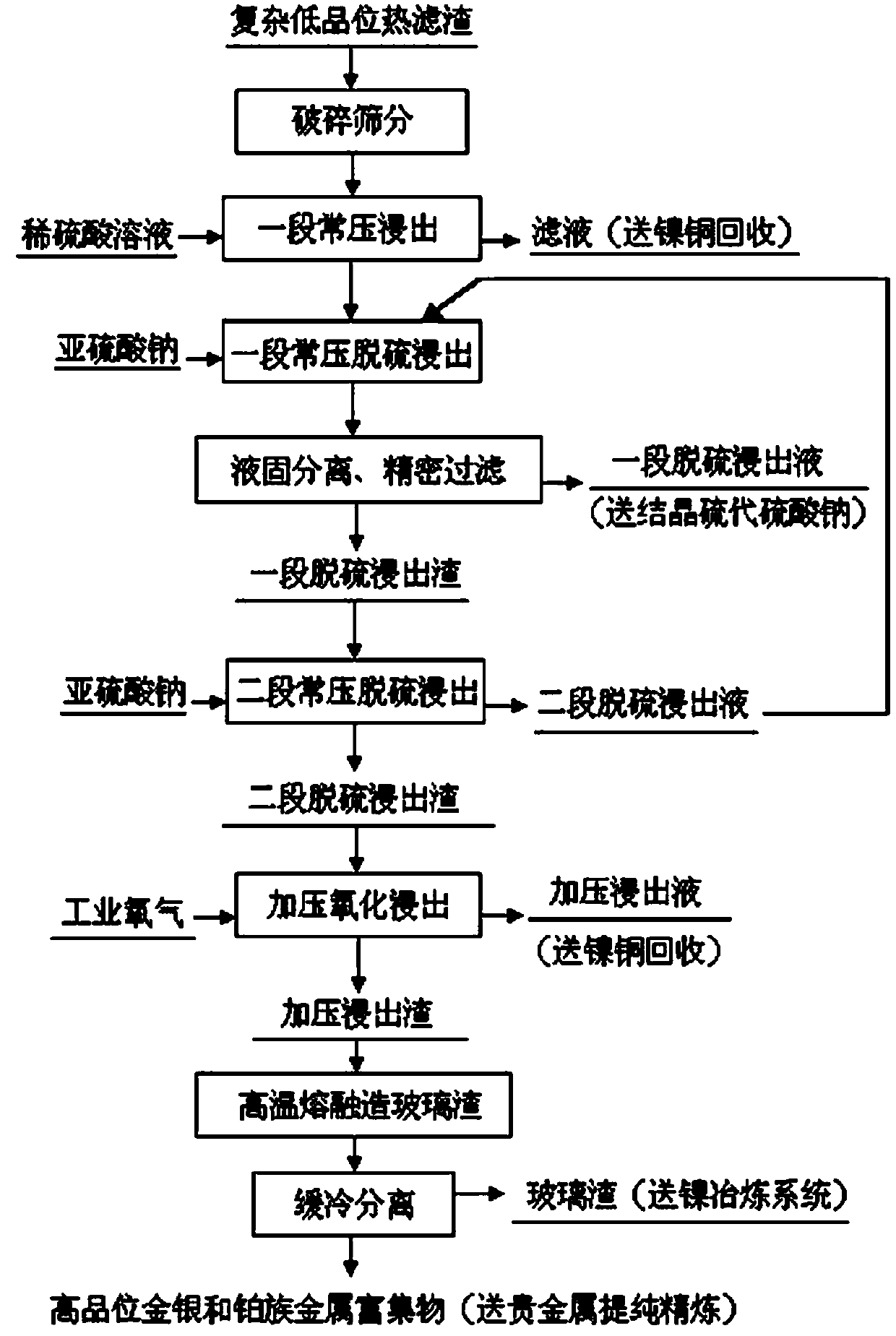

Method used

Image

Examples

Embodiment 1

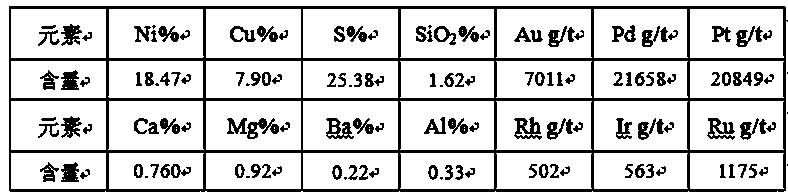

[0048] Crushing and classifying the hot filter residue to obtain the raw material with a particle size not greater than 120 mesh; the chemical composition of the hot filter residue is shown in Table 1.

[0049] Table 1 Chemical composition of hot filter residue

[0050]

[0051]According to the ratio of adding 1kg of raw materials to 6 liters of dilute sulfuric acid, add the raw materials into the dilute sulfuric acid solution with a mass volume concentration of 5g / L, and perform a period of normal pressure leaching at a temperature of 80°C. After leaching for 1 hour, measure the pH value of the leachate , if the pH value of the leaching solution is 1.0 to 3.0, the leaching is finished, filtered and washed to obtain a section of normal pressure leaching solution and a section of normal pressure leaching residue; the chemical composition of a section of normal pressure leaching residue is shown in Table 2.

[0052] Table 2 Chemical composition of the leaching slag from the...

Embodiment 2

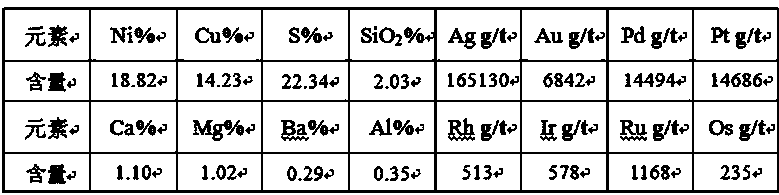

[0083] Crushing and classifying the hot filter residue to obtain the raw material with a particle size of not more than 120 mesh; the chemical composition of the hot filter residue is shown in Table 10.

[0084] Table 10 Chemical composition of hot filter residue

[0085]

[0086] According to the ratio of adding 1kg of raw materials to 10 liters of dilute sulfuric acid, add the raw materials into the dilute sulfuric acid solution with a mass volume concentration of 15g / L, and perform a period of normal pressure leaching at a temperature of 90°C. After 4 hours of leaching, measure the pH value of the leachate , if the pH value of the leaching solution is 1.0 to 3.0, the leaching is completed, filtered and washed to obtain a section of normal pressure leaching solution and a section of normal pressure leaching residue; the chemical composition of a section of normal pressure leaching residue is shown in Table 11.

[0087] Table 11 Chemical composition of leaching slag from t...

Embodiment 3

[0118] Crushing and grading the hot filter residue to obtain the raw material with a particle size of no more than 120 mesh; add the raw material to the dilute sulfuric acid solution with a mass volume concentration of 8g / L according to the ratio of adding 1kg of raw material to 8 liters of dilute sulfuric acid, and heat it at a temperature of 85°C Carry out a section of normal pressure leaching, after 2.5 hours of leaching, measure the pH value of the leachate, if the pH value of the leachate is 1.0 to 3.0, then the leaching is over, filter and wash, and obtain a section of normal pressure leachate and a section of normal pressure leaching residue; initially, the Add water into the reactor, add 300g of anhydrous sodium sulfite per liter of water, add anhydrous sodium sulfite into the mixed solution, after dissolving, add a period of normal pressure leaching residue according to the liquid-solid ratio of 6:1, and then add a concentration of 10 % sodium hydroxide solution, so th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com