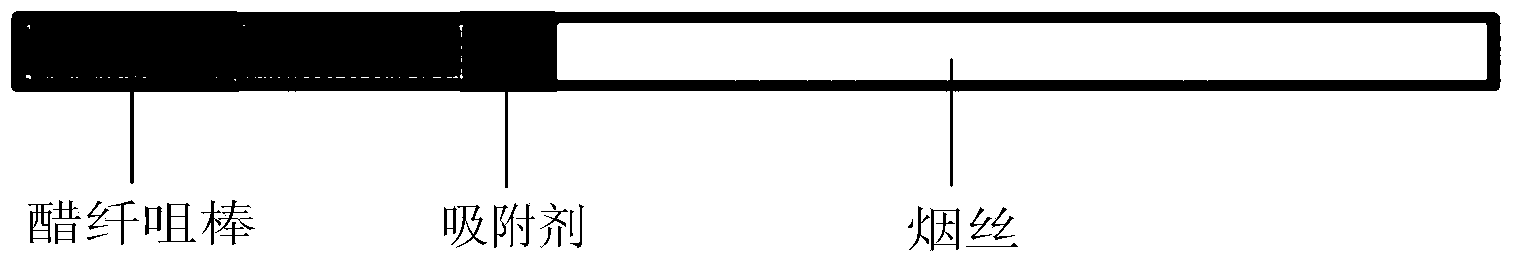

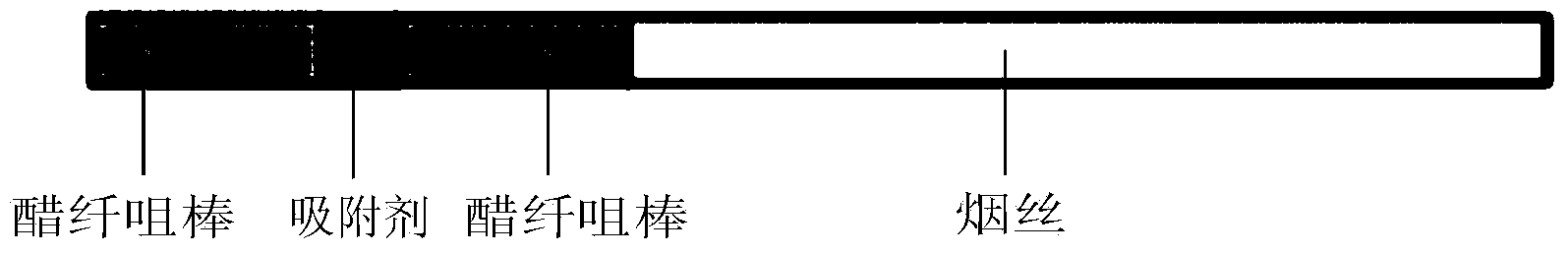

Supported polyamide-amine dendritic macromolecule cigarette smoke heavy metal ion adsorbent and preparation method and application thereof

A cigarette smoke and polyamide technology, which is applied in the field of new cigarette smoke heavy metal polymer adsorption materials, can solve the problems of large amount of adsorbent and limited adsorption capacity, and achieve good effect, increase adsorption strength, and good heavy metal content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

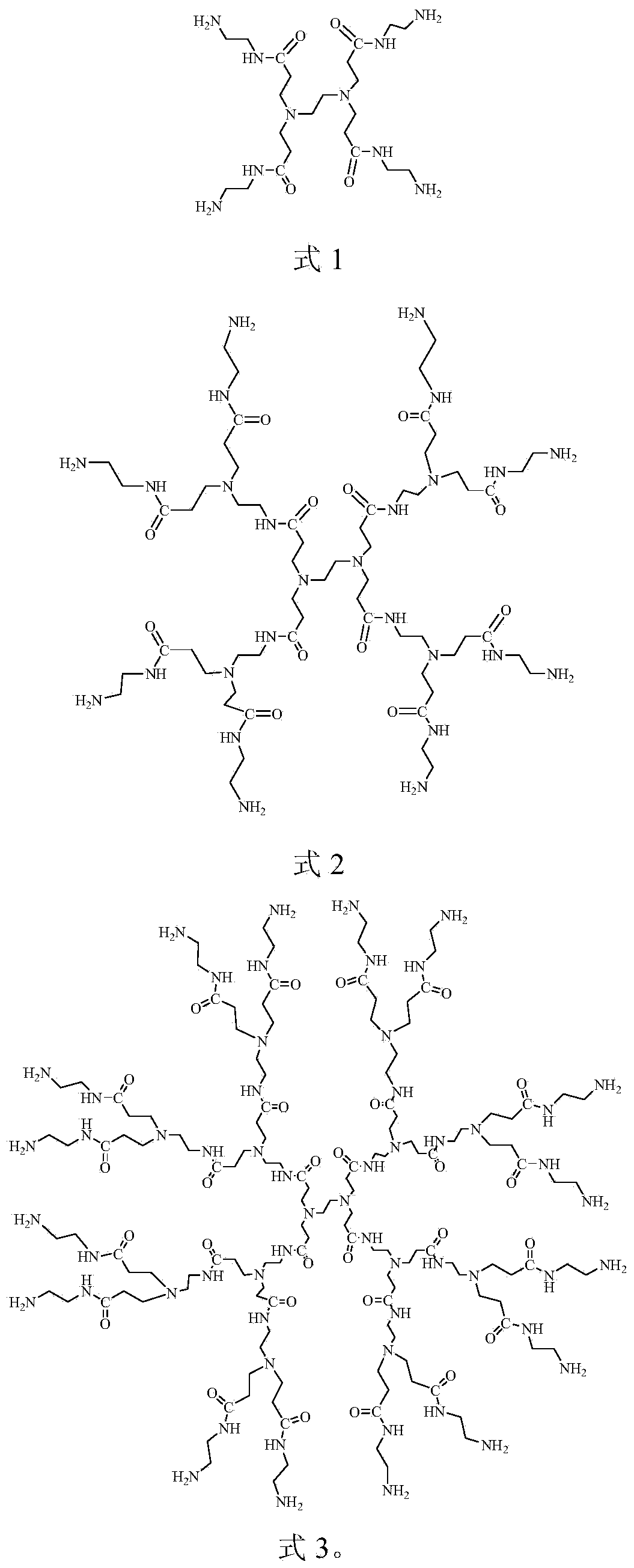

[0030] (1) Preparation of the first generation (G1.0) polyamide-amine dendrimers

[0031] At 25°C, ethylenediamine (EDA) (1.202g, 20mmol) was used as the nucleus of the macromolecule, and methyl acrylate (MA) (6.88g, 80mmol) was reacted in 50mL methanol solution for 72h (first step), After the reaction, the solution was subjected to reduced-pressure rotary evaporation at 70°C. When the solvent was spin-dried, it was cooled to room temperature, methanol was added to the system to dissolve, and then reduced-pressure rotary evaporation was performed at 70°C. Repeat three times to obtain the product, Vacuum drying at 50°C yielded a generation 0.5 (G0.5) macromolecule with four ester functional groups at the end. G0.5 (4.042g, 40mmol of ester group) was dissolved in anhydrous methanol, and then EDA (2.40g, 40mmol) was added dropwise to the system reaction system, and the mixture was reacted at room temperature for 72h (the second step ), after the reaction, the solution was subjec...

Embodiment 2

[0034] (1) The preparation of the first generation (G1.0) polyamide-amine dendrimer is the same as in Example 1.

[0035] (2) Prepare 100g of 5% first-generation (G1.0) polyamide-amine dendrimer solution with distilled water, weigh 100g of 20-100 mesh coarse-pore silica gel, and mix the polyamide-amine dendrimer solution Slowly add to the silica gel, stir evenly at the same time, immerse in equal volume for 2 hours to fully infiltrate; move the wet particles into the oven, bake at 150°C for 12 hours, make the material fully react and dry, cool naturally to room temperature, and sieve to remove The fine powder is 40-60 mesh particles to obtain the first-generation (G1.0) polyamide-amine dendrimer adsorbent loaded on silica gel.

Embodiment 3

[0037] (1) The preparation of the first generation (G1.0) polyamide-amine dendrimer is the same as in Example 1.

[0038] (2) Prepare 100g of 10% first-generation (G1.0) polyamide-amine dendrimer solution with distilled water, weigh 100g of 20-100 mesh coarse-pore silica gel, and mix the polyamide-amine dendrimer solution Slowly add to the silica gel, stir evenly at the same time, immerse in equal volume for 2 hours to fully infiltrate; move the wet particles into the oven, bake at 150°C for 12 hours, make the material fully react and dry, cool naturally to room temperature, and sieve to remove The fine powder is 40-60 mesh particles to obtain the first-generation (G1.0) polyamide-amine dendrimer adsorbent loaded on silica gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com