A novel electronic-grade polyimide film with low linear expansion coefficient and its production method

A technology of polyimide film and low coefficient of linear expansion, which is applied in the field of polyimide film with low coefficient of linear expansion and its production, can solve the problems of high-end electronic products, high coefficient of linear expansion of polyimide, High dimensional stability and other issues, to achieve the effect of large-scale industrial production, low linear expansion coefficient, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

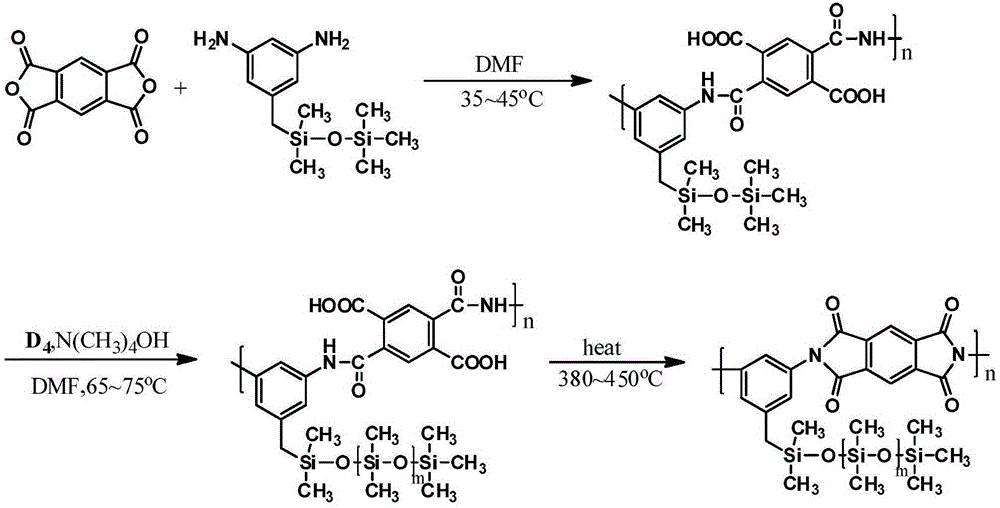

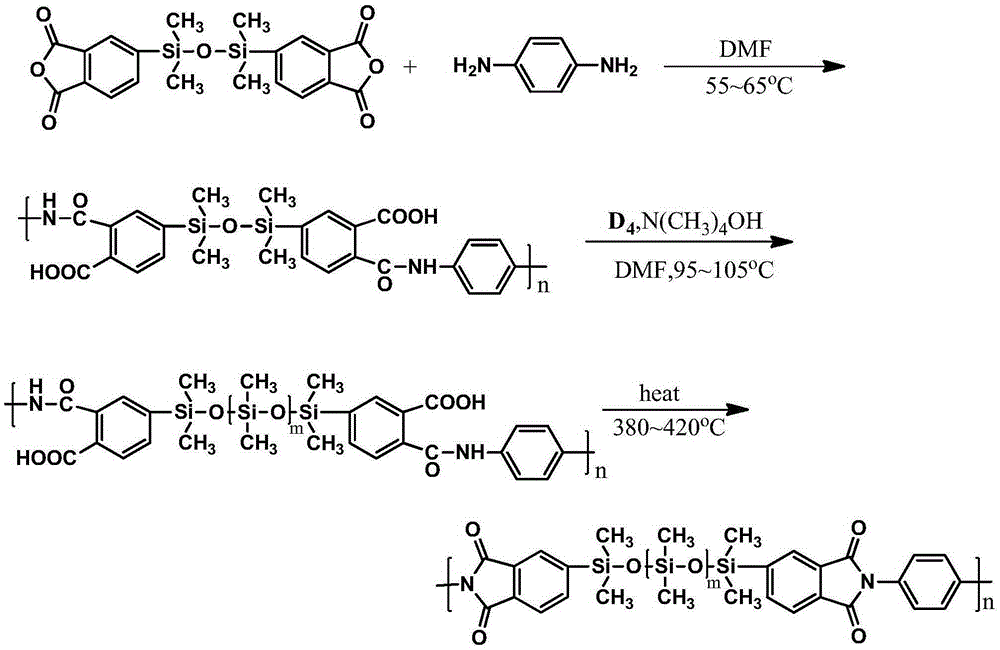

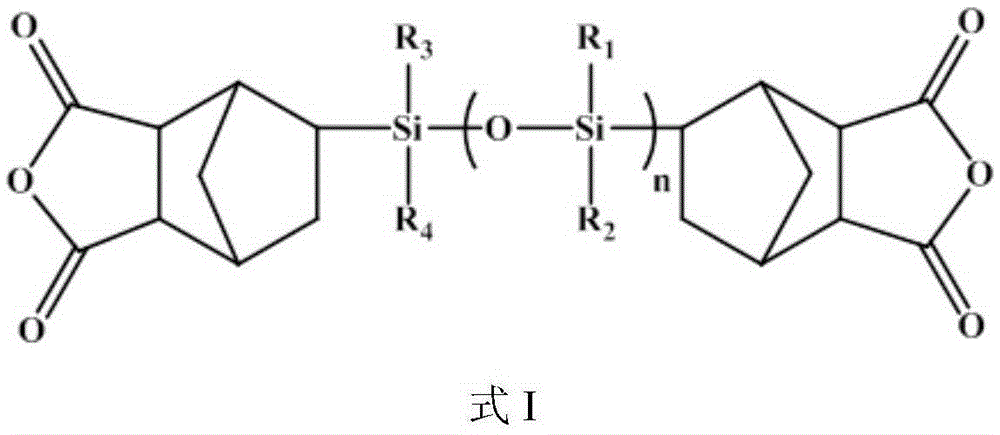

Method used

Image

Examples

Embodiment 1

[0062] Put 500 liters of DMF into the dissolution tank, add 1.00 molar ratio of ODA, start the mixer to stir and dissolve, and the dissolution time is 1 hour. After the diamine monomer is completely dissolved in the polar solvent, stop stirring, and use compressed air to dissolve the diamine monomer. The body solution is pressed into the stainless steel polymerization reaction kettle through the filter, the mixer is started, the cooling water is passed, and then the dianhydride monomer (PMDA, BPDA, BTDA and its composition) is gradually added in 8 times with a total molar ratio of 1.010 to 1.015. . From the 1st to 4th times, the amount of dianhydride added is controlled in equal amounts and at even intervals. A total of 50wt% of the total amount of dianhydride is added in the first 4 times, and from the 5th to the 8th times, each addition is 50wt% of the total amount of the remaining amount. Putting in, checking the viscosity of the resin after 5-10 minutes of stirring and rea...

Embodiment 2

[0066] With reference to the solution polycondensation method of Example 1, using DMF as a solvent, the polyamic acid solution with a solid content of 15 to 20% was obtained by polycondensation of dianhydride and diamine in an equimolar ratio, and then filtered and vacuum defoamed. The mixed polyamic acid solution is cast on the endless steel belt through the extrusion die to form a film, and a gel film with a solid content of 22.5 to 55% is formed through chemical imidization, and then the steel belt is peeled off by a stripping roller, and sent by a silica gel roller. Go to the longitudinal stretching machine and the transverse stretching machine, and carry out biaxial stretching at a temperature of 125 ~ 185 ° C with a stretch ratio of 1.10 ~ 1.35, and then carry out a high temperature of 15 min ~ 25 min in an infrared box at 350 ~ 450 ° C. Complete imidization, heat setting in a high-temperature box at 250-300°C for 5min-8min, corona surface modification, natural cooling, t...

Embodiment 3

[0073] Referring to Example 1, a multi-component blended polyamic acid was synthesized by a step-by-step feeding method.

[0074]Purified and pre-measured in the solvent tank, the mass is 4 times the total amount of dianhydride and diamine monomer anhydrous N, N'-dimethylformamide 85% (parts by weight) and xylene 15% (parts by weight) ) mixed solvent into the dissolution kettle, put 108kg of high-purity p-phenylenediamine and 367kg of APDS into the dissolution kettle through the automatic metering system, start the mixer to stir and dissolve, the dissolution time is not less than 1.0 hours, and the diamine monomer is completely dissolved After soaking in the polar solvent, stop stirring, use compressed air to press the diamine monomer solution into the stainless steel polymerization reaction kettle through the filter, start the stirrer, pass cooling water, and then gradually add the total amount of 8 times under stirring. For 294kg of pyromellitic dianhydride, the amount of di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com