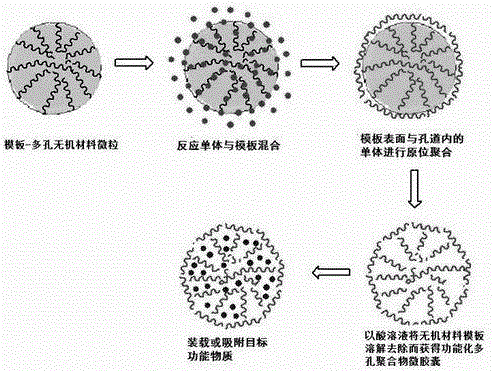

A kind of porous functionalized microcapsule, preparation method and application

A functionalized, microcapsule technology, applied in microcapsule preparations, microsphere preparation, chemical instruments and methods, etc., can solve the problems of waste of raw materials, time-consuming, many steps, etc., and achieve easier size control, simple preparation process, and low price. cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Porous functionalized microcapsules of polyacrylamide-co-styrene-co-methyl methacrylate copolymer

[0023] (1) Mix 85.7g of deionized water, 5mg of sodium polyacrylate, and 14.3g of porous calcium carbonate filter cake with a solid content of 35wt%, and fully disperse them to make a porous calcium carbonate water suspension with a solid content of 5wt% and good dispersibility liquid, spare;

[0024] (2) Stir the aqueous suspension of porous inorganic particles prepared in step (1) under nitrogen flow, control the speed at 300r / min, add 5g of acrylamide, heat up to 60°, stir for 1h, then add azobisisobutyl Add 40 mg of amidine hydrochloride and start timing, and add 3 g of styrene and 2 g of methyl methacrylate dropwise therein within 0.5 h, keep warm at 60° for 4 h after the addition, and vacuum filter the reaction solution after cooling to obtain Cake spare;

[0025] (3) Add 0.1N hydrochloric acid solution dropwise to the filter cake obtained in step (2) u...

Embodiment 2

[0026] Example 2: Porous functionalized microcapsules of polyacrylamide-co-dimethyldiallylammonium chloride-co-methyl methacrylate copolymer

[0027] (1) Mix 33.3g of deionized water, 60mg of sodium hexametaphosphate, and 66.7g of porous calcium carbonate filter cake with a solid content (that is, inorganic powder) of 30wt%, and fully disperse it to make a solid content of 20wt with good dispersion performance % porous calcium carbonate aqueous suspension, set aside. In this embodiment, 66.7g solid content is that the pure calcium carbonate contained in the filter cake of 30wt% is 66.7g * 30%=20g, and water should be 66.7g-20g=44.7g, then the total amount of water in the system is 44.7+33.3=80g, at this time the ratio of deionized water: sodium hexametaphosphate: porous calcium carbonate should be 4:0.003:1.

[0028] (2) Stir the aqueous suspension of porous inorganic particles prepared in step (1) under nitrogen, control the speed at 1000r / min, add 15g of acrylamide and 5g o...

Embodiment 3

[0030] Example 3: Porous functionalized microcapsules of poly-N-isopropylacrylamide-co-dimethyldiallylammonium chloride-co-methyl methacrylate copolymer

[0031] (1) Mix 92g of deionized water, 80mg of sodium silicate, and 8g of porous aerosol silica, and fully disperse to prepare a porous aerosol silica aqueous suspension with a solid content of 8wt% and good dispersibility, and set aside;

[0032] (2) Stir the aqueous suspension of porous inorganic particles prepared in step (1) under nitrogen flow, control the speed at 600r / min, add 6g of N-isopropylacrylamide and dimethyl diallyl ammonium chloride 2g, be warmed up to 40°, after stirring for 1h, add 0.16g of azobisisobutylimidazoline hydrochloride and start timing, and add 16g of methyl methacrylate dropwise therein within 0.5h, keep the temperature for 50 °React for 12h, vacuum filter after the reaction solution is cooled, and obtain a filter cake for subsequent use;

[0033](3) Add 0.1N hydrofluoric acid solution dropwis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com