Method and apparatus for removing contaminants from nitrogen trifluoride

A nitrogen trifluoride, pollutant technology, applied in nitrogen trifluoride, chemical instruments and methods, separation methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

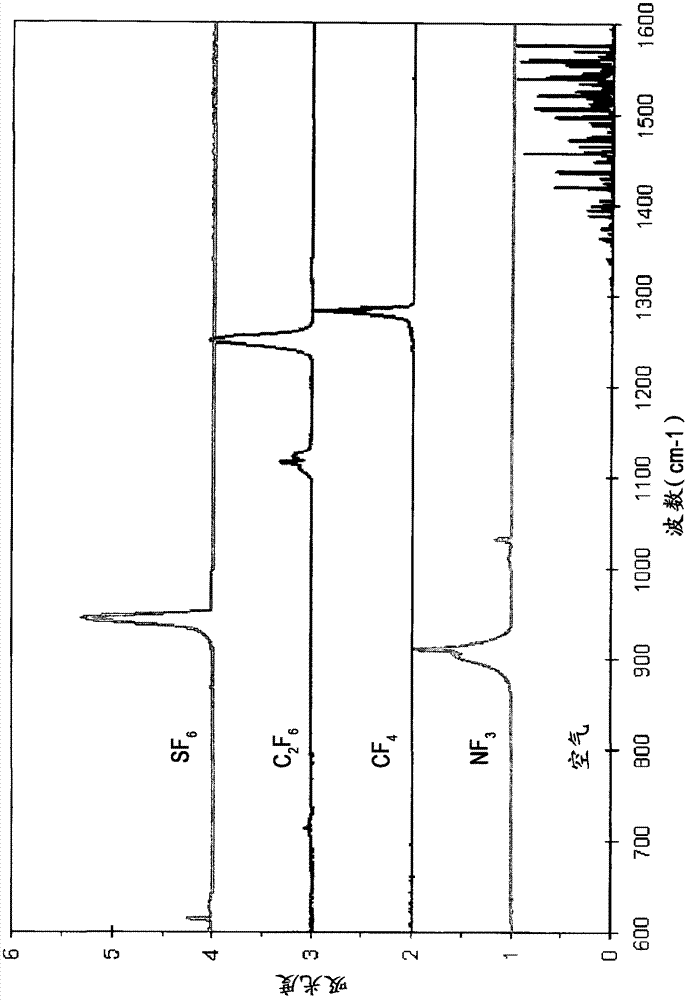

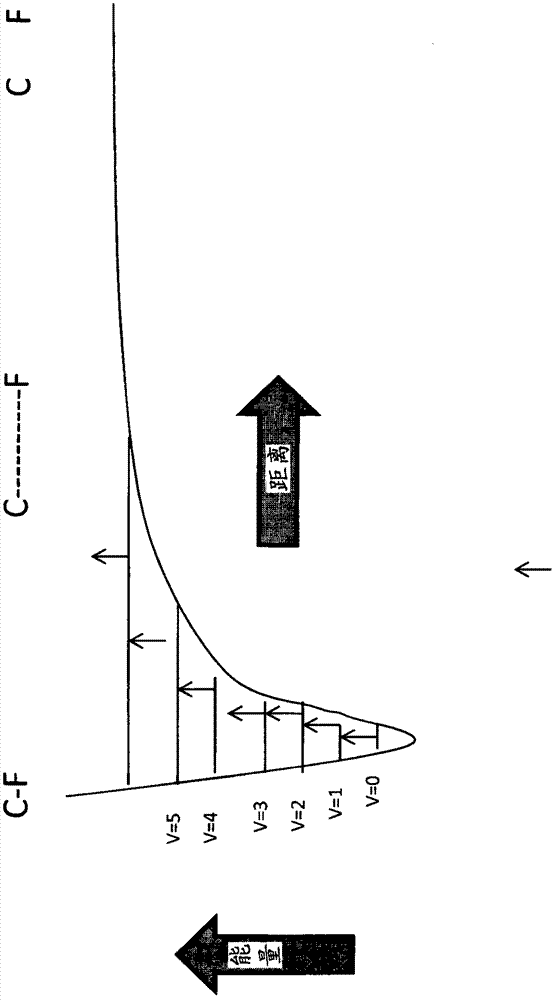

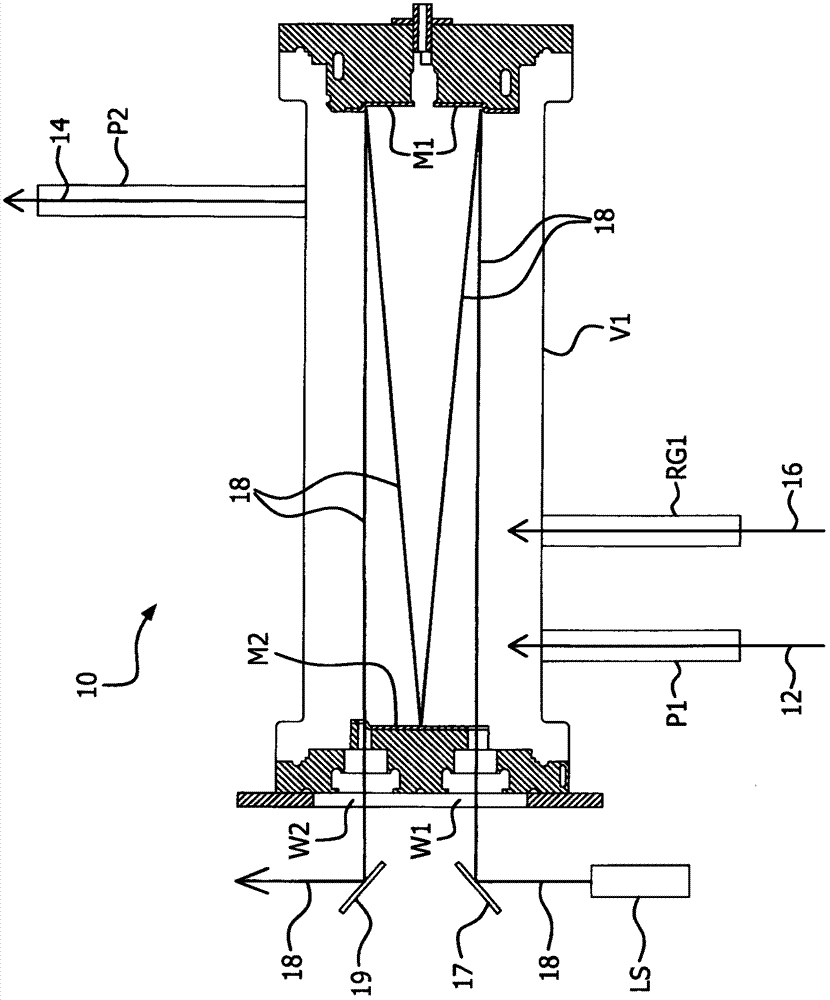

[0062] Use a wave number of 1275cm -1 The light radiation contains CF 4 NF of impurities 3 gas. The light source is multiple quantum cascade lasers (QCL), e.g. focused to provide greater than 10J / cm 2 The QCL of the fluence was from Alpes Lasers (Neuchatel, Switzerland). Contains CF 4 NF of impurities 3 The gas will be contained in a gas container such as a White cell (long-range gas cell) with a volume of approximately 2 L manufactured by CIC Photonics (Albuquerque, NM). The window of the container is transparent to infrared light, for example a window made of potassium bromide (KBr). Using a mass flow controller will contain CF 4 NF of impurities 3 Process gas is provided into the vessel, and the pressure in the vessel is maintained at 500 Pa using a vacuum pump (eg, manufactured by Edwards) and a pressure control valve (eg, manufactured by MKS, Andover, MA). The procedure is to evacuate the gas container to a pressure below 5Pa, and then isolate the gas container f...

Embodiment 2

[0064] NF by irradiating the process gas under nearly collision-free conditions using techniques including trapped ion cyclotron resonance (ICR) spectroscopy 3 CF contained in the process gas 4 Impurities are dissociated. Quantum cascade lasers (QCL), such as those from Alpes Lasers (Neuchatel, Switzerland), can be used for the radiation. The light source has a 1275cm -1 wavenumber and 10w cm -2 Strength of. The output of the quantum cascade laser (QCL) will be focused transversely to the magnetic field through the 92% transparent mesh to irradiate ions in the source region of the ICR cell. A collimated 6 mm diameter infrared beam is reflected by a polished mirror on the base plate back through the source region. Electron beam pulse application (10 ms duration) to generate ionic species, which is then present for several seconds during which CF 4 Impurities dissociate. Contains CF 4 Neutral NF 3 The pressure of the process gas is 133×10 -7 to 133×10 -6 Pa, the neutr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com