Method for preparing manganese dioxide/mesoporous carbon nanometer graded composite electrode material

A manganese dioxide and composite electrode technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of high resistance and low specific capacity of carbon materials, achieve high specific capacity, and improve electric double layer capacitance , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Add 0.6761g manganese sulfate monohydrate and 0.9128g ammonium persulfate into 45mL deionized water successively, stir for 60min, pour into the reaction kettle and put the reaction kettle into the oven, keep it in the oven at 100°C for 10h, and remove the black precipitate obtained from the reaction Wash and dry with deionized water and absolute ethanol to obtain sea urchin-like manganese dioxide with a hollow structure.

[0028] Dissolve 0.0625g of 0.2M hydrochloric acid solution and 0.1000g of F127 in 4g of absolute ethanol, and after stirring evenly, add 0.1300g of tetraethyl orthosilicate and 0.3125g of phenolic resin ethanol solution with a mass fraction of 20%, and continue stirring for 20min to obtain mixture.

[0029] Add 0.1000 g of the above-prepared sea urchin-like manganese dioxide into the above-mentioned mixed solution, ultrasonically stir it for 3 hours, let it stand at room temperature to volatilize and self-assemble for 5 hours, put it in an oven at 100...

Embodiment 2

[0031] Add 0.6761g manganese sulfate monohydrate and 0.9128g ammonium persulfate into 45mL deionized water successively, stir for 60min, pour into the reaction kettle and put the reaction kettle into the oven, keep it in the oven at 100°C for 10h, and remove the black precipitate obtained from the reaction Wash and dry with deionized water and absolute ethanol to obtain sea urchin-like manganese dioxide with a hollow structure.

[0032] Dissolve 0.25g of 0.2M hydrochloric acid solution and 0.4000g of F127 in 6g of absolute ethanol, and after stirring evenly, add 0.5200g of tetraethyl orthosilicate and 1.25g of phenolic resin ethanol solution with a mass fraction of 20%, and continue stirring for 20min to obtain mixture.

[0033] Add 0.1000 g of the above-prepared sea urchin-like manganese dioxide into the above-mentioned mixed solution, ultrasonically stir it for 3 hours, let it stand at room temperature to volatilize and self-assemble for 5 hours, put it in an oven at 100° C....

Embodiment 3 2

[0034] Example 3 Characterization of manganese dioxide / mesoporous carbon nanoscale composites

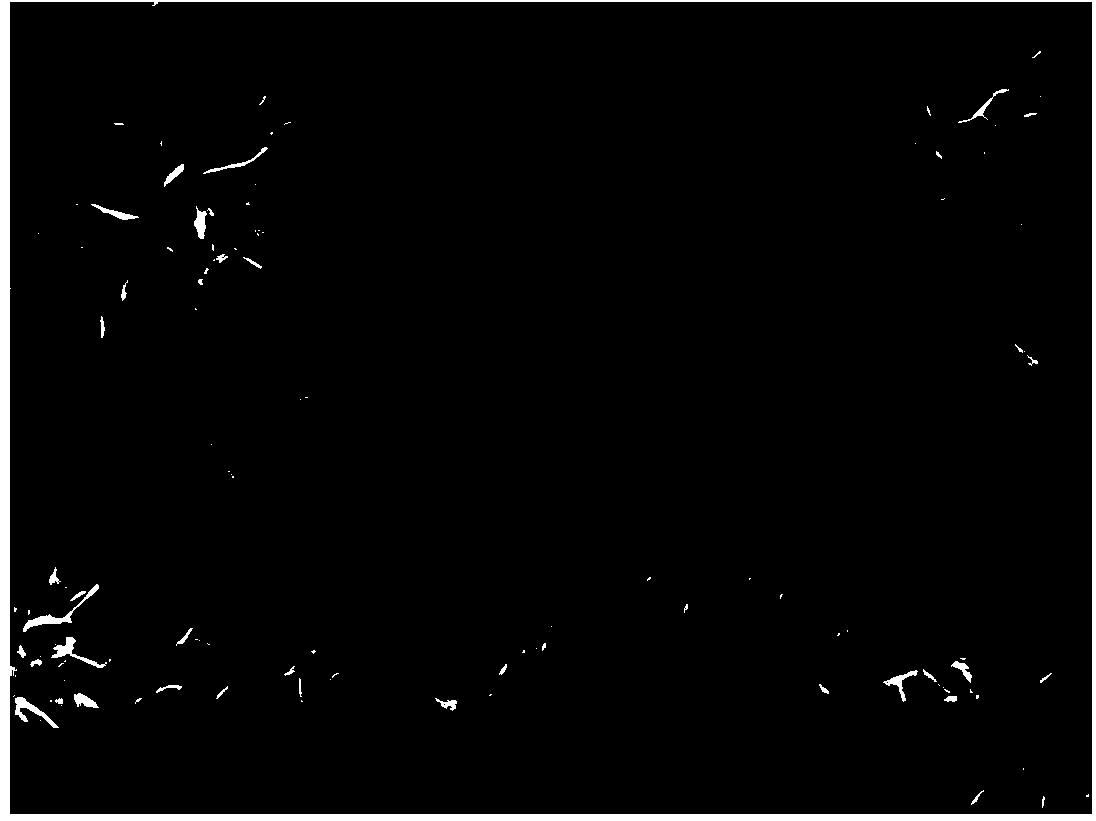

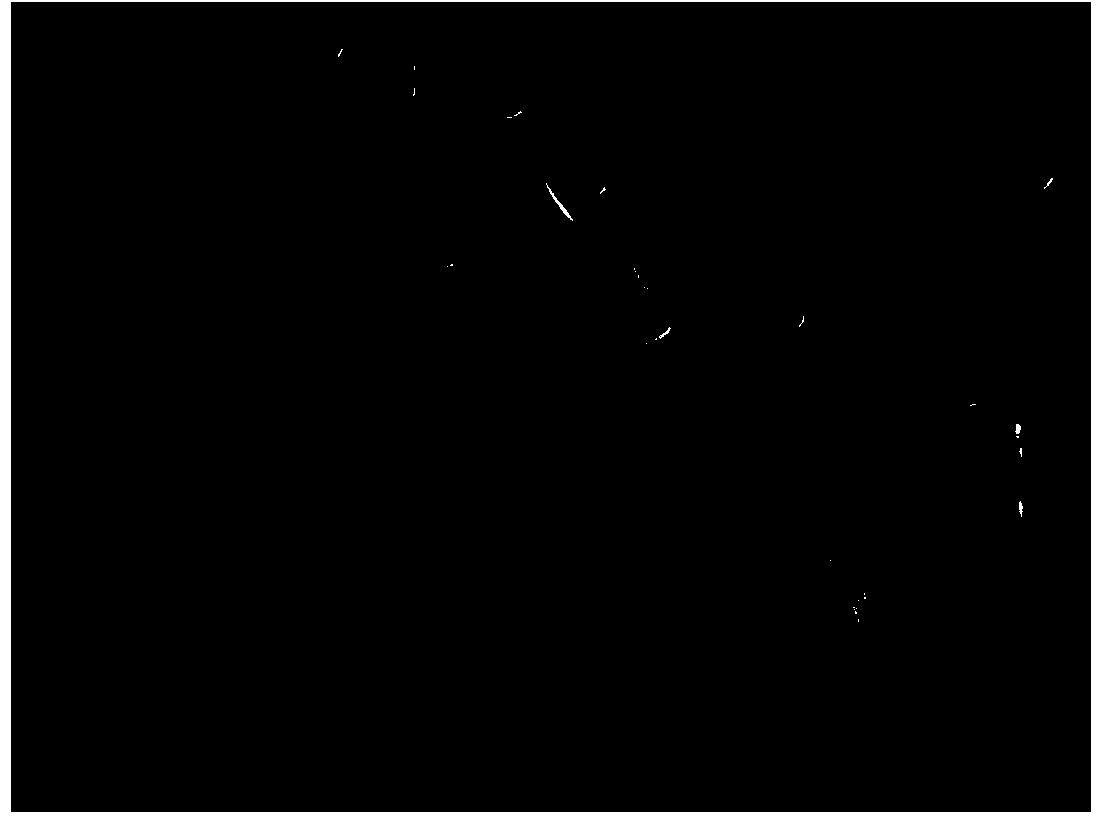

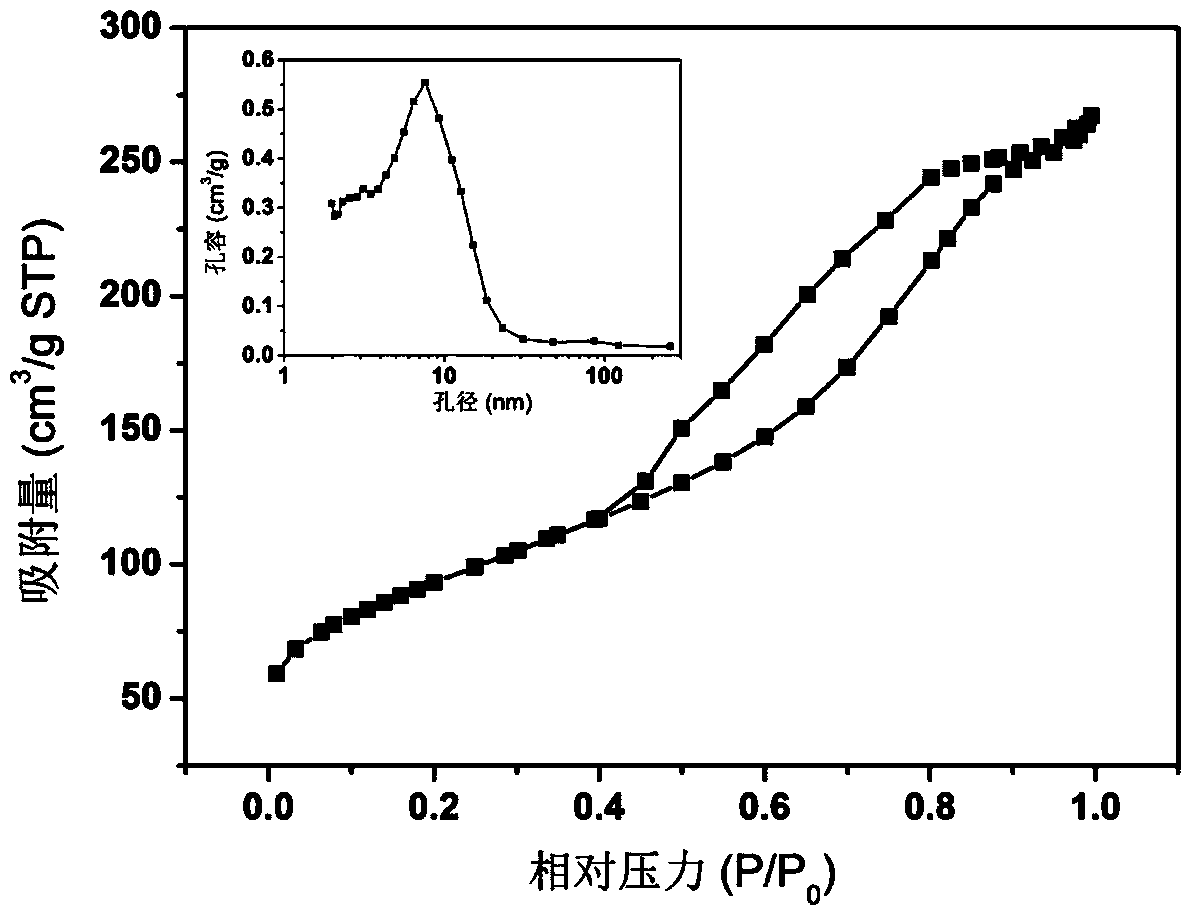

[0035] Field emission electron microscopy (HITACHI S4800) and nitrogen adsorption-desorption (Micromeritics ASAP2020) analyzers were used to analyze the surface morphology and chemical structure of the manganese dioxide / mesoporous carbon nanocomposites prepared in the above-mentioned examples 1 and 2. Characterization analysis, results such as figure 1 , 2 , 3 and Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com