A method for homogeneously preparing carboxychitin with low degree of deacetylation and its application

A technology with low deacetylation degree carboxyl group and deacetylation degree, which is applied in the field of material science, can solve problems such as difficulty in ensuring product quality and uniformity of substitution degree, difficulty in controlling the reaction process, and large environmental pollution, achieving high application development value, replacing The effect of uniform degree and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

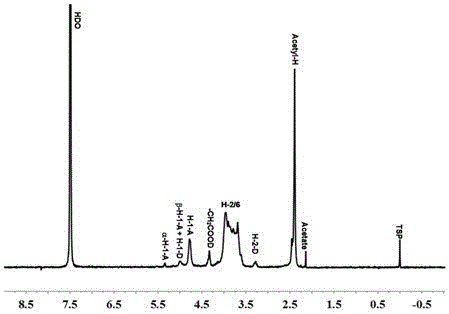

Embodiment 1

[0027] First prepare a mixture of sodium hydroxide: urea: pure water = 6:3:91 (mass ratio), add 0.5g of chitin to 100g of the above mixture and mix well at -12~-20 o Freeze at C for 72 hours, thaw at 5-12 o C fully stirred to obtain a 0.5wt% homogeneous chitin aqueous solution. Add a mixed solution containing 7g of chloroacetic acid, 4.6g of sodium hydroxide, 1g of urea and 20mL of pure water to the homogeneous chitin aqueous solution. o C (low temperature first, then slowly increase the temperature, control the reaction solution to be a homogeneous system) and stir for 8 hours, then adjust the pH value to 6.9 with 1M hydrochloric acid, and dialyze with distilled water for 7 days to remove small molecular substances such as urea and salt in the solution , freeze-dried to obtain sponge powder carboxyl-modified chitin. Compared with the raw material chitin spectrogram, the infrared spectrogram recorded after the product was acidified with hydrochloric acid, at 1720 cm -1 A n...

Embodiment 2

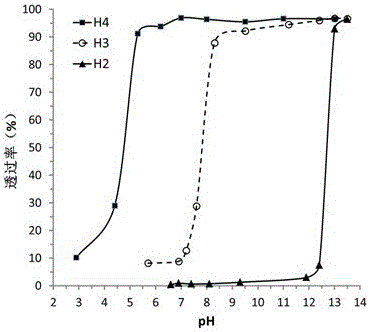

[0029] First prepare a mixture of sodium hydroxide: urea: pure water = 8:4:88 (mass ratio), add 1.2g of chitin to 30g of the above mixture and mix well at -30 o Freeze at C for 36 hours and stir in time, after thawing, store in 2-8 o C fully stirred to obtain a 4wt% homogeneous chitin aqueous solution. Add a solution containing 2.8g of chloroacetic acid, 1.4g of sodium hydroxide, 0.5g of urea and 10mL of pure water to the homogeneous chitin aqueous solution. o Stir the reaction at C for 6h, 14~16 o The reaction was stirred for 24 hours at C, and the reaction solution was controlled to be a homogeneous transparent system. Use 1M hydrochloric acid to adjust the pH value to 7.5, use 1L acetone to precipitate, filter and wash the precipitate with 80% (v / v) ethanol aqueous solution to remove small molecules such as urea and salts, and dry at 50°C to obtain powdered carboxy-modified carapace element, the yield is 89%. The product is then dissolved in water, dialyzed to remove a ...

Embodiment 3

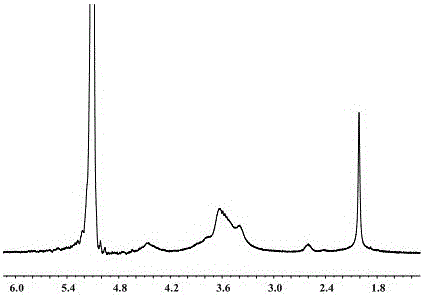

[0031] First prepare a mixture of sodium hydroxide: urea: pure water = 11:4:85 (mass ratio), add 1.0g of chitin to 100g of the above mixture and mix well at -30 o Freeze at C for 24 hours and stir in time, after thawing, store in 1-5 o C under full stirring to obtain a 1wt% homogeneous chitin aqueous solution. Add a mixed solution containing 2.33g of chloroacetic acid, 1.5g of sodium hydroxide, 0.45g of urea and 10mL of pure water into the homogeneous chitin aqueous solution. o Stir the reaction at C for 6h, then at 14~16 o The reaction was stirred for 12 hours at C, and the reaction solution was controlled to be a homogeneous transparent system. Use 1M hydrochloric acid solution to adjust the pH value to 7.2, use 1L acetone to precipitate, filter and wash with ethanol / water (80%, v / v) to remove small molecules such as urea and salts in the precipitate, and dry at 50°C to obtain powder carboxyl-modified chitin. The product was analyzed by proton nuclear magnetic spectrum t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com