Indium tin oxide nanowire array composite, method for preparing indium tin oxide nanowire array composite and application of indium tin oxide nanowire array composite in solar cell

An indium tin oxide nanometer and composite material technology, which is applied to circuits, capacitors, electrical components and other directions, can solve the problems of increasing battery series resistance and affecting battery stability, and achieves the effects of good stability, low cost and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

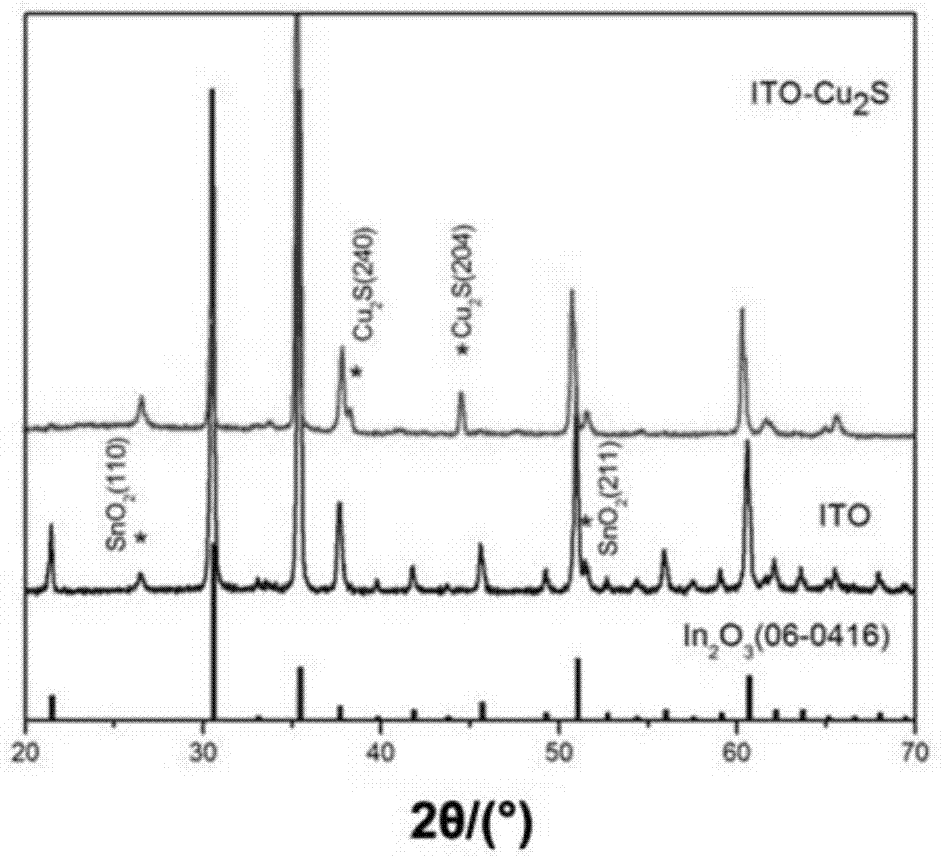

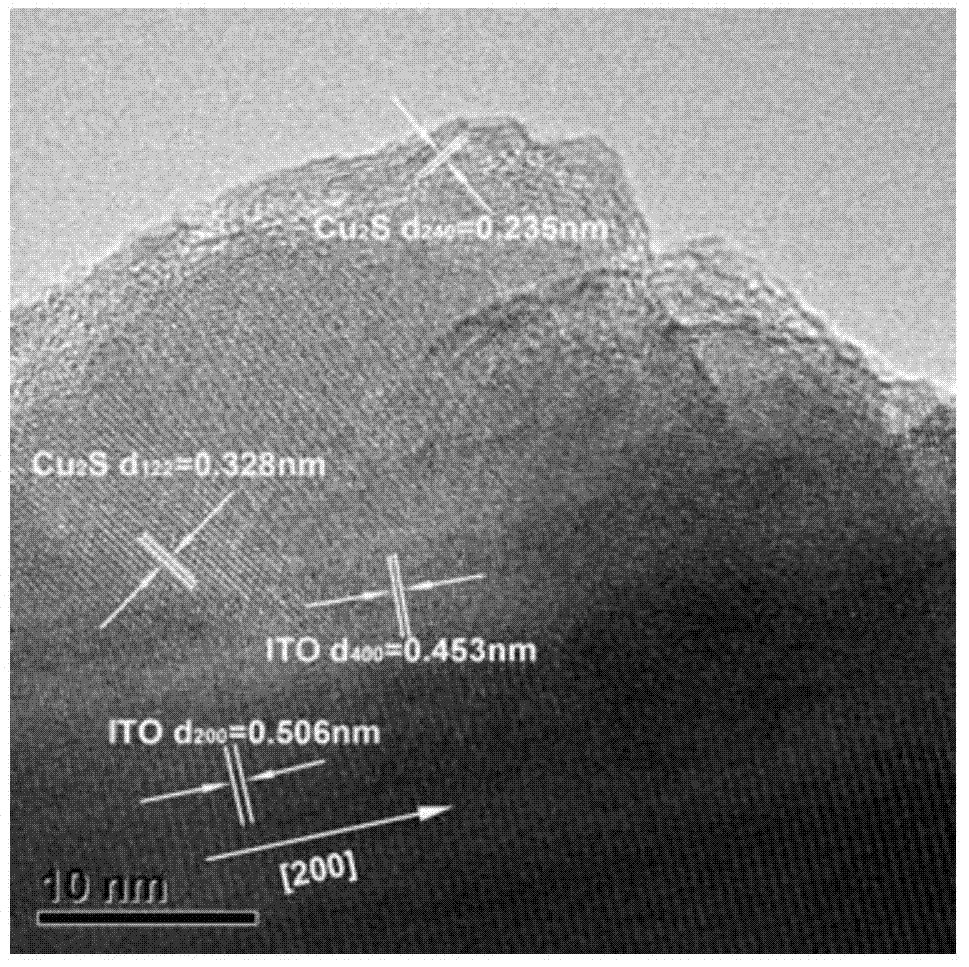

[0043] Embodiment 1, wrapping Cu 2 Indium tin oxide nanowire array composite of S nanoparticles (Cu 2 SITO) and its application

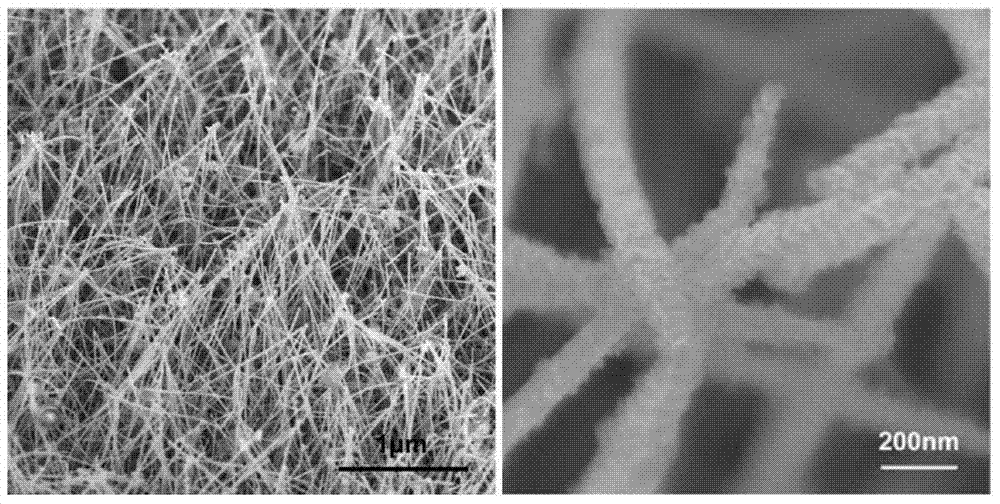

[0044] Metal indium powder and tin powder are heated to 800°C in a tube furnace according to the molar ratio of 10:1, then the source area is reacted at 800°C for 20 minutes and then cooled to room temperature naturally, and placed in the deposition area of the tube furnace in advance A certain length of ITO nanowire arrays will grow on the FTO conductive glass sputtered with Au particles (average particle size is 5 nm) at the position (temperature is about 400 °C).

[0045] Select an ITO nanowire array with an average length of 10 microns (the diameter of the nanowire is about 120 nanometers) as the loaded substrate, and place the ITO nanowire array in a pre-prepared 200mL aqueous solution (containing 20mM cadmium chloride, 66mM ammonium chloride and 140mM thiourea, pH adjusted to 9.5), reacted at 25°C for 2 hours; then transferred to 10mL aque...

Embodiment 2

[0053] Embodiment 2, wrapping Cu 2 Indium tin oxide nanowire array composite of S nanoparticles (Cu 2 SITO) and its application

[0054] The specific preparation method is basically the same as that in Example 1, except that: an ITO nanowire array with an average length of 3 microns (wherein, the diameter of the nanowire is about 100 nanometers) is selected as the loaded matrix, and Cu 2 SITO.

[0055] Cu prepared by this embodiment 2 SITO was used as the counter electrode, and the quantum dot-sensitized solar cell device was assembled according to the same method as in Example 1, and its photoelectric conversion performance was tested, and the photoelectric conversion efficiency was 3.37%.

Embodiment 3

[0056] Embodiment 3, wrapping Cu 2 Indium tin oxide nanowire array composite of S nanoparticles (Cu 2 SITO) and its applications

[0057] The specific preparation method is basically the same as that in Example 1, the difference is that an array of ITO nanowires with an average length of 7 microns (wherein the diameter of the nanowires is about 110 nanometers) is selected as the loaded matrix, and finally Cu 2 SITO.

[0058] Cu prepared by this embodiment 2 SITO was used as the counter electrode, and the quantum dot-sensitized solar cell device was assembled according to the same method as in Example 1, and its photoelectric conversion performance was tested, and the photoelectric conversion efficiency was 3.54%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com