A preparation technique for spacecraft-used molybdenum/platinum/silver/ layered metal matrix composite materials

A composite material and preparation process technology, applied in sustainable manufacturing/processing, semiconductor device, final product manufacturing, etc., can solve the difficulty of reasonable microstructure confirmation annealing process, the difficulty of molybdenum/platinum bonding interface, the difference in thermal expansion coefficient, etc. problem, to achieve the effect of low thermal expansion coefficient, good thermal shock resistance, good weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention is described in detail in conjunction with the embodiments and accompanying drawings.

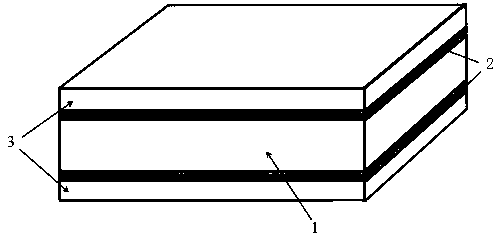

[0044] figure 1 is a schematic diagram of the structure of molybdenum / platinum / silver layered metal matrix composites, in which, 1-matrix metal is molybdenum metal with a thickness of 12 m; 2 - middle layer metal, platinum metal, thickness 0.5 m; 3 - surface metal, silver, thickness 5 m.

[0045] The specific implementation steps are as follows:

[0046] 1. Degreasing and cleaning the molybdenum metal surface

[0047] The length 180mm and width 120mm cleaned with alcohol The molybdenum metal foil with a thickness of 15 μm is completely immersed in 1L of degreasing solution (50mL of 37% concentrated hydrochloric acid + 50mL of 98% concentrated sulfuric acid + distilled water) for 3 minutes, then taken out and immersed in deionized water for 5 minutes for cleaning, and the cleaning is carried out 3 times.

[0048] 2. Molybdenum metal surface etching

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com