Supported hierarchical pore Beta molecular sieve based catalyst and preparation method and application thereof

A multi-stage pore and load-type technology, applied in the direction of molecular sieve catalysts, separation methods, chemical instruments and methods, etc., can solve the problems of unfavorable soot particle diffusion and mass transfer, low specific surface area of metal oxides, and limited agglomeration of active components problems such as bulk, to achieve good hydrothermal stability, cost and energy savings, and good catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

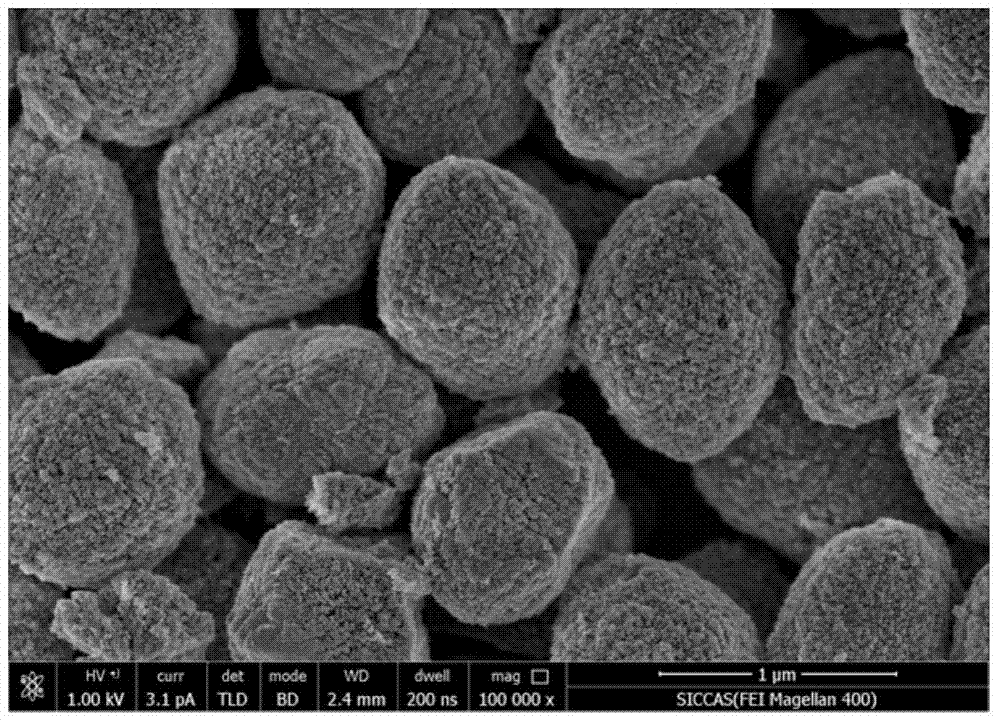

[0037] Add 0.012mol tetraethylammonium hydroxide (TEAOH) and 0.002mol NaCl to 6mL water, stir well at room temperature and then add 0.025mol SiO 2, stirred until clear, and then added 2 mL of an aqueous solution containing 0.001 mol of sodium aluminate to obtain a mixed aqueous solution. Then, 2 mL of a surfactant cetyltrimethylammonium bromide (CTAB) aqueous solution with a concentration of 0.05 mol / L was added to the mixed aqueous solution, stirred vigorously at 80° C. for 3 hours, and then the resulting solution was charged into polytetrafluoroethylene In a vinyl fluoride hydrothermal kettle, carry out hydrothermal crystallization reaction at 150°C for 24 hours, centrifuge, wash the sample, dry at 100°C overnight, and then roast at 550°C for 8 hours to remove attached inorganic salts and organic matter; the roasted The powder was dispersed in 20mL of 0.5M NaOH aqueous solution, treated in a water bath at 80°C for 4 hours, centrifuged and dried at 150°C to obtain a Na-loaded...

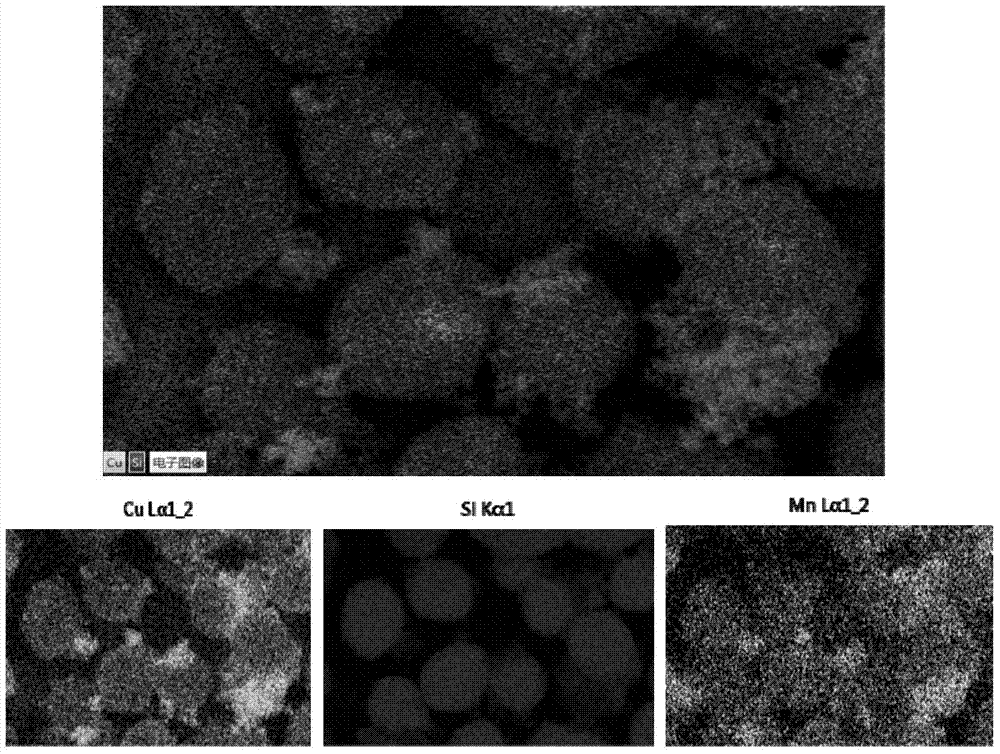

Embodiment 2

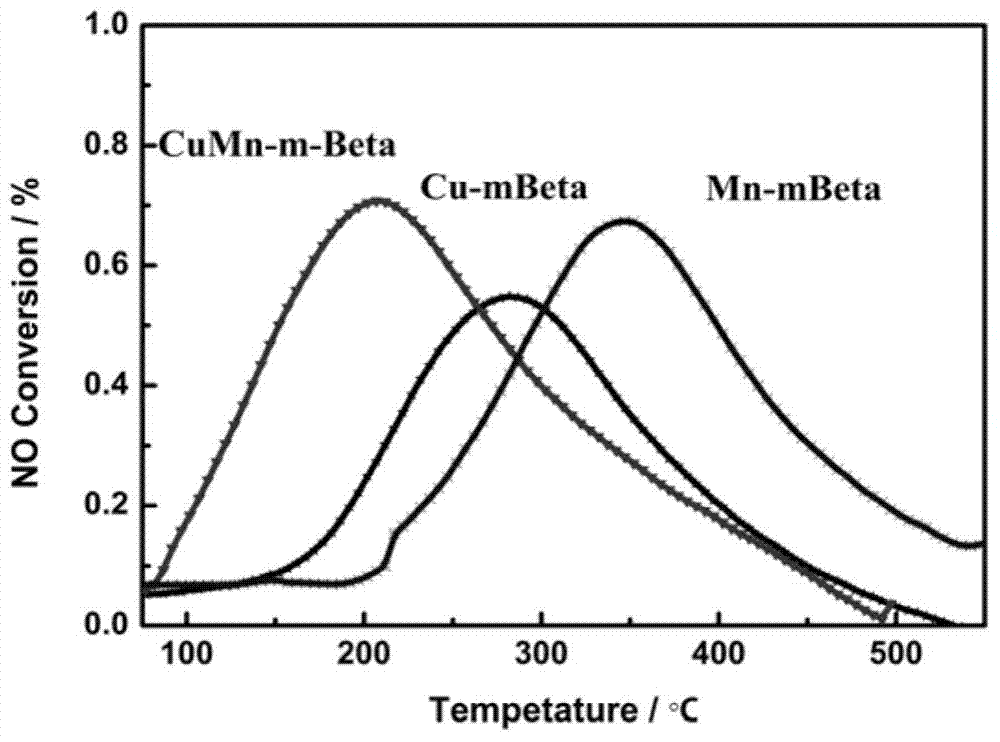

[0040] Take 1 g of Na-mBeta powder in Example 1, mix it with 50 mL of 0.5 mol / L copper nitrate solution, stir for 4 hours in a water bath at 80°C for ion exchange, centrifuge after the reaction, and wash until there are no metal ions in the lotion , dried at 100°C; then repeat the above ion exchange process 3 times. Finally, it was calcined at 550° C. for 8 hours to obtain a Cu-loaded hierarchical porous Beta molecular sieve material, which was denoted as Cu-mBeta.

Embodiment 3

[0042] Take 1 g of Na-mBeta powder in Example 1, mix it with 50 mL of 0.1 mol / L potassium permanganate solution, stir for 4 hours in a water bath at 80°C for ion exchange, centrifuge after the reaction, and wash until there is no Metal ions were dried at 100°C; then the above ion exchange process was repeated three times. Finally, it was calcined at 550° C. for 8 hours to obtain a Mn-supported hierarchical porous Beta molecular sieve material, which was denoted as: Mn-mBeta.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com