Base material of inorganic coating and application of base material

A technology of base materials and inorganic coatings, applied in art coatings, coatings, etc., can solve the problems of easy aging of coatings, poor weather resistance, internal micropores, etc., and achieve pollution-free energy, strong weather resistance, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment one: a kind of base material of inorganic coating, described base material is the mixture of liquid silica sol and calcium carbonate, takes by weighing 100 grams of liquid silica sol (solid content is 30%), 100 grams of powder calcium carbonate respectively, Pour the silica sol into the speed-adjusting dispersion kettle, add calcium carbonate while stirring, and then stir at a high speed to disperse evenly.

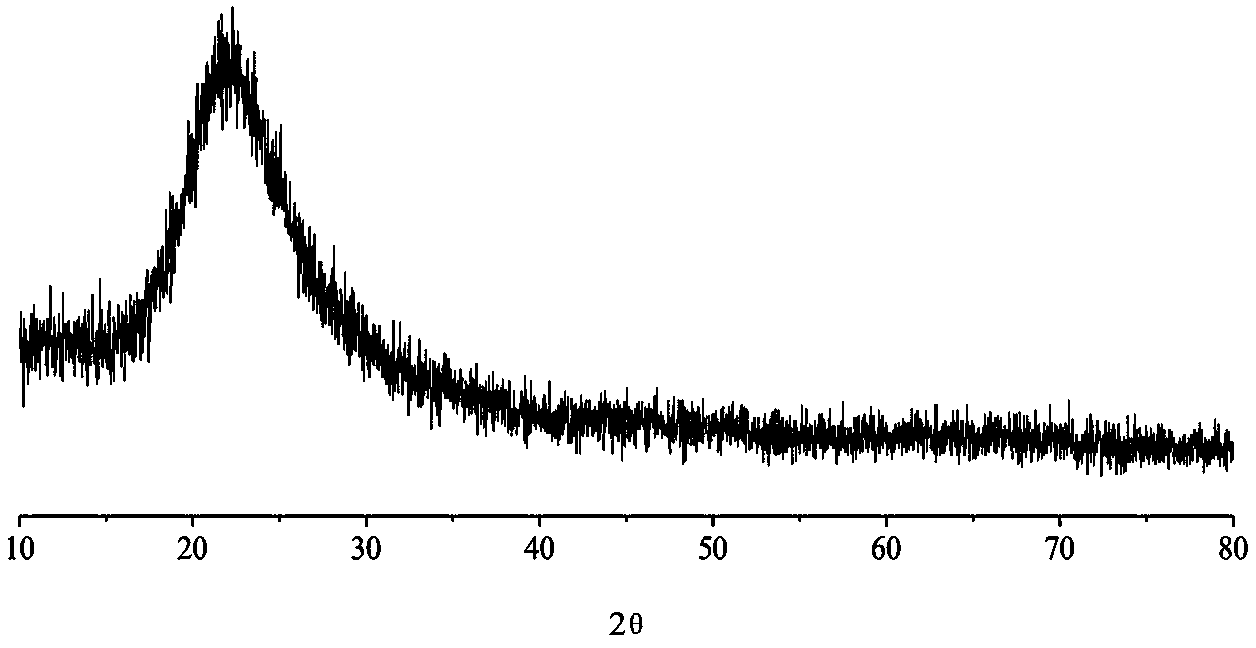

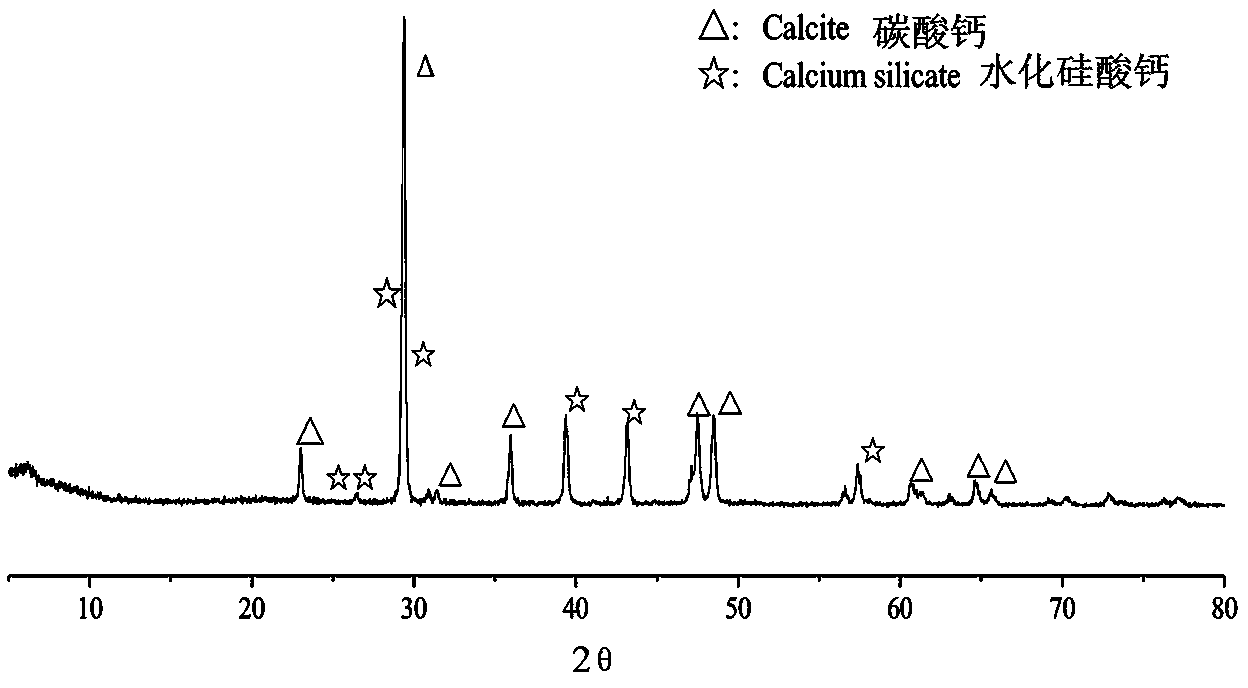

[0030] figure 1 It is the XRD diffraction pattern of silica sol raw material, it is a kind of amorphous silicon dioxide; figure 2 It is the XRD diffraction pattern of the hardened product after the product of this embodiment is placed in the air for 3 days, wherein it can be found that the amorphous silicon dioxide has all disappeared, and calcium silicate hydrate with a good crystal structure has been generated, and the remaining part is not Reactive calcium carbonate. Mechanistically, the amorphous active silica in the aqueous solution of silica sol...

Embodiment 2

[0035] Embodiment 2: first weigh 100 grams of liquid silica sol (solid content=30%, hereinafter referred to as silica sol, the same below), and 300 grams of powdered calcium carbonate, and then inject the silica sol into the speed-regulating dispersion kettle, Then gradually add calcium carbonate and auxiliary materials, the amount of auxiliary materials is not more than 20% of the total mass, then stir at a high speed to disperse evenly, make a slurry, put it in a barrel and store it in a sealed manner. The storage time reaches 6 months, and the seven-day test The compressive strength is greater than 12MPa, the whiteness is greater than 85%, and the Mohs hardness is greater than 5.

Embodiment 3

[0036] Embodiment three: first mix 100 grams of silica sol, about 200 grams of powdered calcium carbonate, 20 grams of expanded perlite and 10 grams of EVA redispersible latex powder with a glass transition temperature MFT of about zero degrees and then adjust the speed Disperse evenly in the same way in the dispersing kettle. This product can be used as an inorganic fireproof and thermal insulation coating, and the storage time can reach 6 months after being loaded into barrels. Compared with the product of Example 2, its anti-crack performance is improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| impermeability | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com