Chinese caterpillar fungus combination containing plants and fungal polysaccharide and preparation method thereof

A technology of fungal polysaccharides and compositions, applied in the field of Cordyceps composition containing plant and fungal polysaccharides and its preparation, can solve the problems of slow effect, high pollution, low extraction rate, etc., achieve comprehensive nutritional components, low process energy consumption, The effect of many types of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: Cordyceps composition

[0029] Raw materials: Edible and medicinal fungi: Hericium erinaceus 200g, Poria cocos 200g, Agaricus blazei 200g, white fungus 200g;

[0030] Chinese herbal medicine: 300g medlar, 300g jujube, 300g yam, 300g lotus seeds.

[0031] Strains: Cordyceps sinensis, Cordyceps militaris.

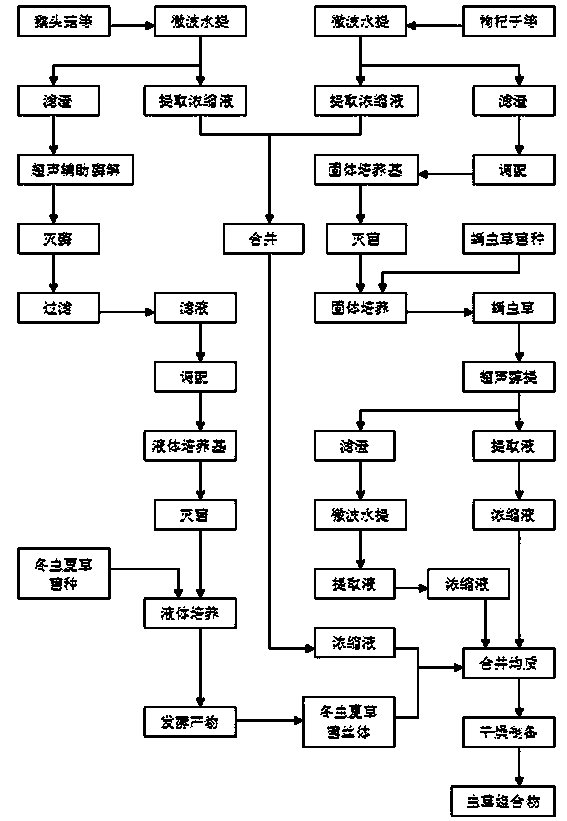

[0032] Preparation Process:

[0033] (1) Pre-treatment: Crush the qualified raw materials through 10 meshes respectively, and weigh them according to the above ratio for later use.

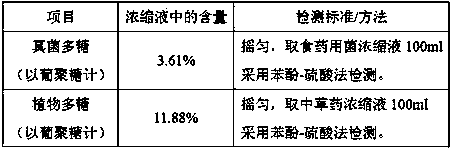

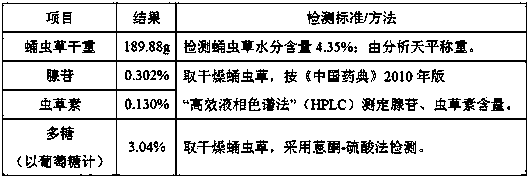

[0034] (2) Extraction and concentration: Use microwave continuous extraction equipment (Wenzhou Shenhua Light Industry Machinery Co., Ltd.), with a volume of 40L, add drinking water to the raw materials of edible and medicinal fungi and Chinese herbal medicines according to the ratio of material to liquid 1:10, soak for 2 hours, microwave Extraction conditions: power 2.4KW, frequency 2450MHz, temperature 60°C, stirring speed 150rpm, extract for 10 min, filter throu...

Embodiment 2

[0057] Embodiment 2: Cordyceps composition capsule

[0058] Raw materials: take 400 g of the Cordyceps composition of the above-mentioned Example 1.

[0059] Excipients: 400g milk powder, 400g starch, 400g maltodextrin, 400g microcrystalline cellulose, 10g magnesium stearate.

[0060] Preparation Process:

[0061] (1) Pretreatment: crush the Cordyceps composition through an 80-mesh sieve; pass the milk powder, starch, maltodextrin, microcrystalline cellulose, and magnesium stearate through an 80-mesh sieve for later use.

[0062] (2) Mixing: Weighing according to the above ratio and mixing by equal increment method.

[0063] (3) Filling: Fill the mixture into capsules with a capsule filling machine, 0.3g / capsule. polishing.

[0064] (4) Bottling: bottle the filled capsules. 60 capsules / bottle.

Embodiment 3

[0065] Embodiment 3: Cordyceps composition granules

[0066] Raw materials: take 400 g of the Cordyceps composition of the above-mentioned Example 1.

[0067] Excipients: 400g white sugar, 400g glucose, 400g maltodextrin, 400g microcrystalline cellulose.

[0068] Preparation Process:

[0069] (1) Pre-treatment: respectively crush the Cordyceps composition and white sugar through a 100-mesh sieve; pass through a 100-mesh sieve for maltodextrin and microcrystalline cellulose for later use.

[0070] (2) Granulation: Weigh and mix according to the above ratio, add 1000ml, 70% edible alcohol to granulate, pass through a 20-mesh nylon net, and spread it on a baking tray.

[0071] (3) Drying: Dry the material at 65°C for 3 hours.

[0072] (4) Granulation: The dried material is granulated, passed through a 20-mesh stainless steel wire mesh, and the fine powder below 60 mesh is screened out to re-granulate.

[0073] (5) Packing: the sieved material is packed into granules by a gran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com