Oil-water separation granule and preparation method thereof

A technology of oil-water separation and pellets, which is applied in the direction of separation methods, liquid separation, chemical instruments and methods, etc., can solve the problems of complex and cumbersome preparation methods, unstable hydrophobicity, and inability to recycle, and achieves wide application prospects and no heavy metals Residual, easy-to-recycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

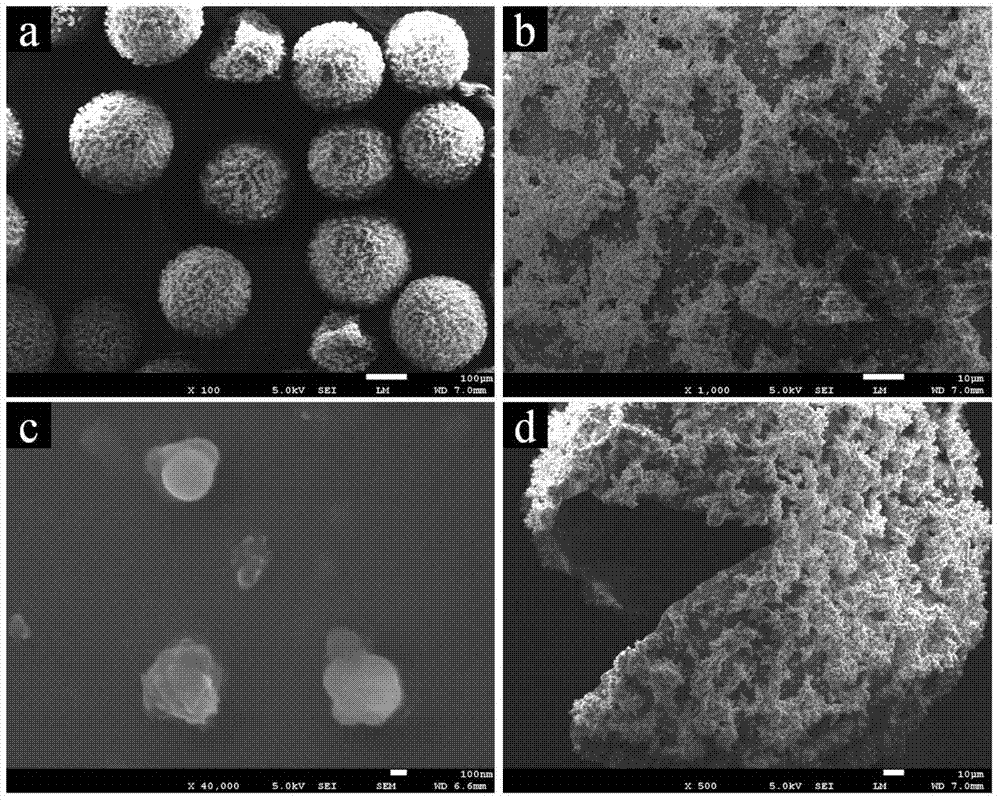

Embodiment 1

[0030] Step 1: Mix 2.5g of urea and 6.33g of 37% formaldehyde solution by mass, adjust the pH to 8 with 1mol / L sodium hydroxide, stir and react at 70°C for 1h, and prepare a soluble prepolymer of urea-formaldehyde aqueous solution.

[0031] Step 2: Mix all the urea-formaldehyde prepolymer aqueous solution obtained in step 1 with 75ml of an aqueous solution containing 0.55% ethylene-maleic anhydride copolymer and 0.35% resorcinol to obtain an aqueous phase, and adjust the aqueous phase with an aqueous citric acid solution After the pH reached 1.5, 10 g of hexamethylene diisocyanate was added dropwise, and stirred at room temperature for 20 minutes at a speed of 600 rpm, then reduced to 200 rpm and reacted at 25°C for 40 minutes, then heated to 55°C for 1 hour, and cooled to room temperature to terminate the reaction. The resulting product was washed with water, filtered, and dried at room temperature for 48 hours for later use.

[0032] Step 3: Mix the dry product obtained in ...

Embodiment 2

[0038] Step 1: Mix 2.5g of urea and 6.33g of 37% formaldehyde solution by mass, adjust the pH to 8 with 1mol / L sodium hydroxide, stir and react at 70°C for 1h, and prepare a soluble prepolymer of urea-formaldehyde aqueous solution.

[0039] Step 2: Mix all the urea-formaldehyde prepolymer aqueous solution obtained in step 1 with 75ml of an aqueous solution containing 0.55% ethylene-maleic anhydride copolymer and 0.35% resorcinol to obtain an aqueous phase, and adjust the aqueous phase with an aqueous citric acid solution After the pH reached 1.5, 10 g of hexamethylene diisocyanate was added dropwise, and stirred at room temperature for 20 minutes at a speed of 800 rpm, then reduced to 200 rpm and reacted at 25°C for 40 minutes, then heated to 55°C for 1 hour, and cooled to room temperature to terminate the reaction. The resulting product was washed with water, filtered, and dried at room temperature for 48 hours for later use.

[0040] Step 3: Mix the dry product obtained in ...

Embodiment 3

[0046] Step 1: Mix 2.5g of urea and 6.33g of 37% formaldehyde solution by mass, adjust the pH to 8 with 1mol / L sodium hydroxide, stir and react at 70°C for 1h, and prepare a soluble prepolymer of urea-formaldehyde aqueous solution.

[0047] Step 2: Mix all the urea-formaldehyde prepolymer aqueous solution obtained in step 1 with 75ml of an aqueous solution containing 0.55% ethylene-maleic anhydride copolymer and 0.35% resorcinol to obtain an aqueous phase, and adjust the aqueous phase with an aqueous citric acid solution After the pH reached 1.5, 10g of 1H, 1H, 2H, 2H-perfluorooctyltriethoxysilane was added dropwise, and stirred at room temperature for 20min at a speed of 700rpm, then reduced to 200rpm and reacted at 25°C for 40min, then heated to 55°C ℃ for 1 h, cooled to room temperature to terminate the reaction, the resulting product was washed with water, filtered, and dried at room temperature for 48 h for use.

[0048] Step 3: Mix the dry product obtained in Step 2 wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com