A kind of organic solvent absorbent and preparation method thereof

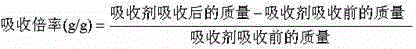

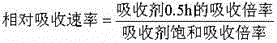

An organic solvent and absorbent technology, applied in the field of organic solvent absorbent and its preparation, can solve the problems of poor reusability, unfavorable material bonding, slow absorption speed, etc., achieves fast absorption speed, broad development and application prospects, absorption High magnification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

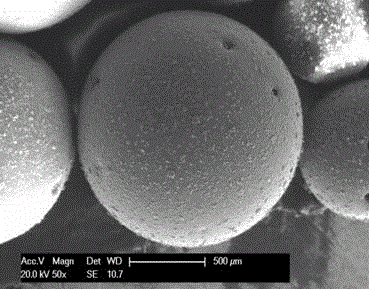

Image

Examples

preparation example Construction

[0028] A preparation method of an organic solvent absorbent, comprising the following steps:

[0029] 1) Add dispersant and water into a four-necked flask equipped with a thermometer, a nitrogen port, a reflux condenser and a stirrer, and stir at 40-80°C for 20-60 minutes to fully dissolve it;

[0030] 2) Mix acrylates, methacrylates, styrene, crosslinking agent and initiator evenly to obtain a mixed solution;

[0031] 3) Control the rotation speed of the stirrer at 250-350rpm, add the mixture in step 2) dropwise into the four-necked flask, keep stirring during the dropwise addition, and then react at 60-85°C for 4-7 hours, the reaction Stir continuously during the process, then mature at 90°C for 1 hour, and filter to obtain the product;

[0032] 4) The product was washed with distilled water and dried under vacuum at 50°C for 24 hours to obtain an organic solvent absorbent.

[0033] Its raw material components are calculated by weight: 300-900 parts of water, 50-250 parts ...

Embodiment 1

[0044] A preparation method of an organic solvent absorbent, comprising the following steps:

[0045] 1) Add 0.05g of polyvinyl alcohol and 60g of water into a four-necked flask equipped with a thermometer, a nitrogen port, a reflux condenser and a stirrer, and stir at 60°C for 30 minutes to fully dissolve;

[0046] 2) Mix 10 g of butyl acrylate, 20 g of styrene, 0.03 g of divinylbenzene and 0.12 g of dibenzoyl peroxide to obtain a mixed solution;

[0047] 3) Control the rotation speed of the stirrer to 300rpm, add the mixed liquid in step 2) dropwise into the four-necked flask, stir continuously during the dropwise addition, and then react at 80°C for 5 hours, stirring continuously during the reaction process, Then mature at 90°C for 1 hour, and filter to obtain the product;

[0048] 4) The product was washed with distilled water and dried under vacuum at 50°C for 24 hours to obtain an organic solvent absorbent. The absorption rate of this absorbent to toluene is 21g / g, and t...

Embodiment 2

[0050] A preparation method of an organic solvent absorbent, comprising the following steps:

[0051] 1) Add 0.1 hydroxyethyl cellulose and 90 g of water into a four-neck flask equipped with a thermometer, nitrogen port, reflux condenser and stirrer, and stir at 50°C for 40 minutes to fully dissolve;

[0052] 2) Mix 12.5g of ethyl acrylate, 2g of lauryl methacrylate, 18.5g of styrene, 0.06g of ethylene glycol dimethacrylate and 0.15g of azobisisobutyronitrile to obtain a mixed solution;

[0053] 3) Control the rotation speed of the stirrer to 350rpm, add the mixed liquid in step 2) dropwise into the four-necked flask, stir continuously during the dropwise addition, and then react at 75°C for 6 hours, stirring continuously during the reaction process, Then mature at 90°C for 1 hour, and filter to obtain the product;

[0054] 4) The product was washed with distilled water and dried under vacuum at 50°C for 24 hours to obtain an organic solvent absorbent. The absorption rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com