Vascularizing tissue structure with microfluid passage and preparation method thereof

A technology of microfluidic channels and tissue structures, applied in biochemical equipment and methods, devices of human tubular structures, blood vessels, etc., can solve problems such as the inability to prepare vascularized tissue and organ structures, and achieve the convenience of nutrient exchange and cell attachment Attached, it facilitates the exchange of nutrients and maintains a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

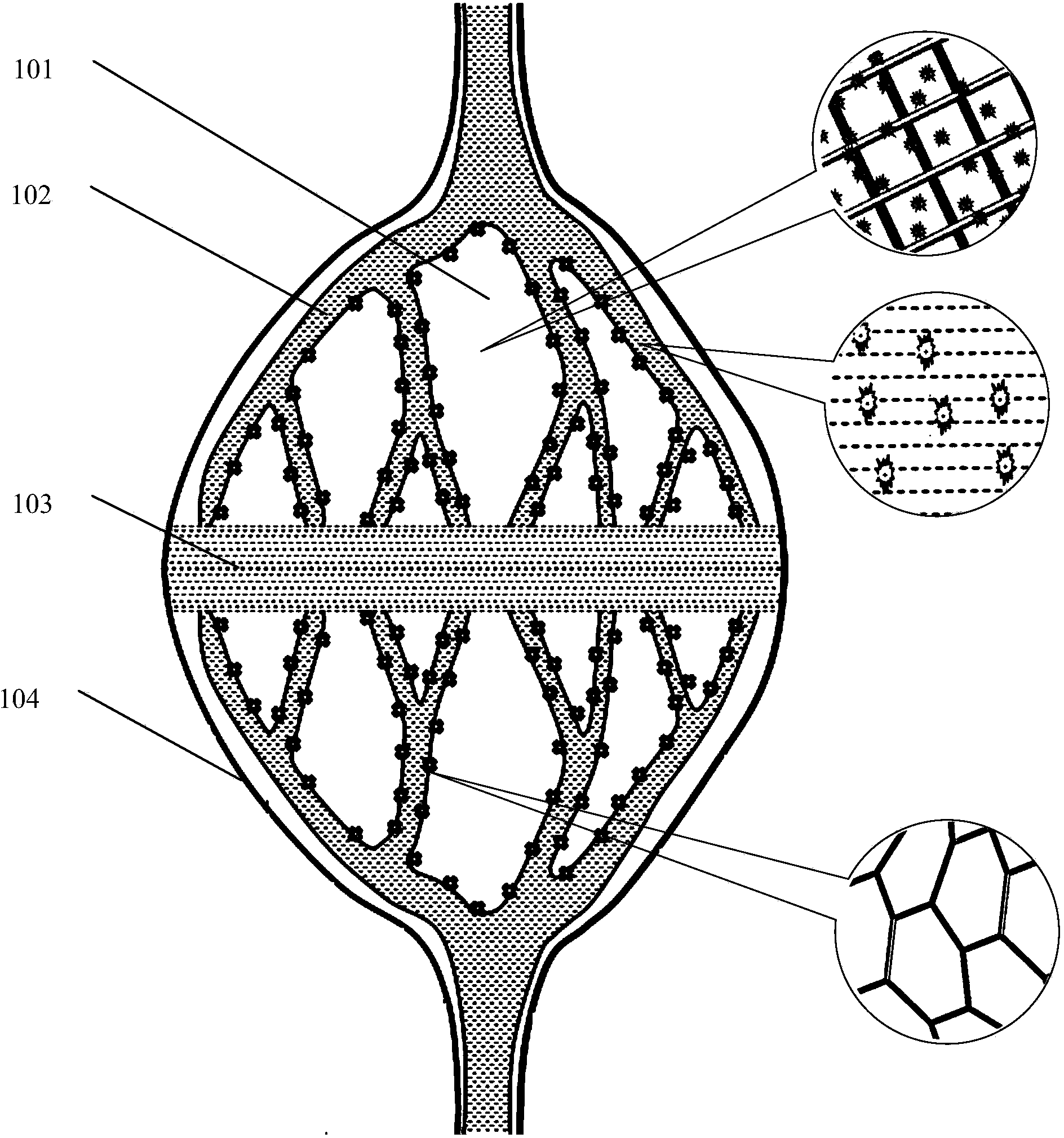

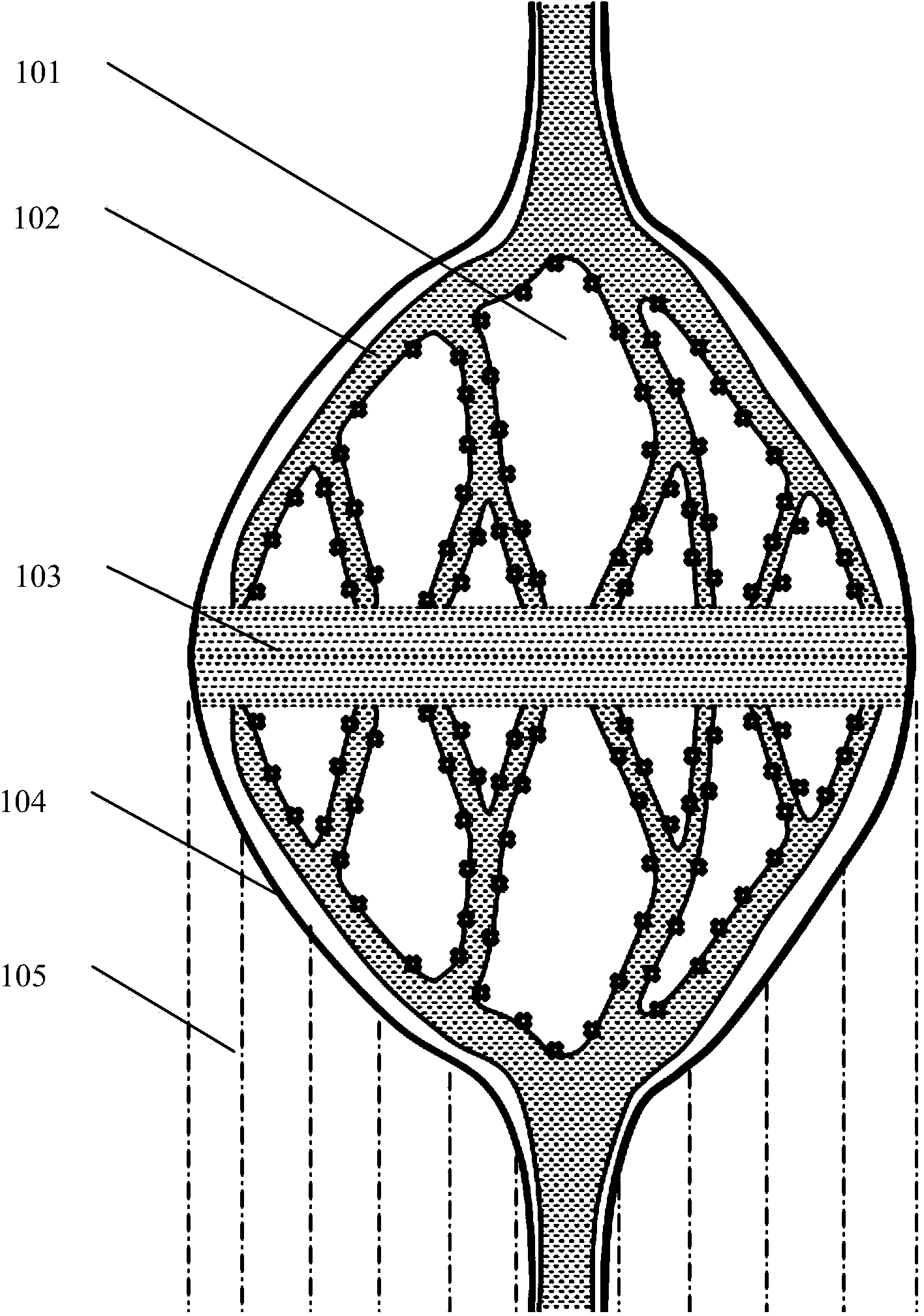

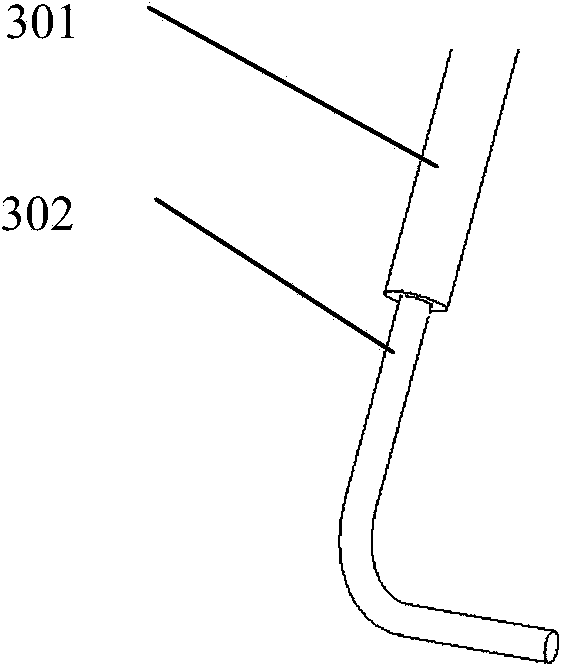

[0041] A method for preparing a vascularized tissue structure with a microfluidic channel provided by the present invention is characterized in that the method comprises the following steps: 1) using a computer to design a three-dimensional model of the vascularized tissue structure with a microfluidic channel; 2) Composite multi-nozzle rapid prototyping equipment is adopted, and the temperature of the forming room is controlled at 40°C to -30°C; the nozzle components of the equipment include extrusion nozzles, drip nozzles and spray nozzles; the prepared natural polymer water containing cells The gel, the dilute solution containing or not containing cells and the synthetic polymer solution that can maintain cell survival are respectively loaded into different types of nozzle assemblies; 3) using extrusion nozzle assemblies to print at least one layer of natural polymer hydrogel or Synthesizing a polymer solution to obtain a supporting part; 4) Printing at least one layer of th...

Embodiment 1

[0045] Example 1: Preparation of vascularized liver tissue with microfluidic channels

[0046] (1) Cell extraction: human adipose stem cells (ADSC) and hepatocytes (Hep) were extracted, cultured and passaged.

[0047] (2) Preparation of hydrogel: Dissolve gelatin and sodium alginate powder in culture medium (DMEM, dulbecco's modified eagle medium) respectively to obtain a gelatin solution with a mass volume concentration of 10% and a mass volume concentration of 2% The sodium alginate solution is mixed with the above gelatin solution, sodium alginate solution equal volumes to obtain hydrogel stand-by.

[0048] (3) Preparation of synthetic polymer solution: the degradable polycarbonate was dissolved in tetraethylene glycol to obtain a solution with a mass volume concentration of 2% and a mass volume concentration of 25% for use.

[0049](4) Preparation of cell-containing matrix material: mix hepatocytes (Hep), dimethyl sulfoxide cryopreservation agent and the above-mentioned h...

Embodiment 2

[0052] Example 2: Preparation of Vascularized Adipose Tissue with Microfluidic Channels

[0053] (1) Cell extraction: human adipose stem cells (ADSC) were extracted, cultured and passaged.

[0054] (2) Preparation of hydrogel: Dissolve the natural polymer material powder in DMEM culture fluid to obtain a gelatin solution with a mass volume concentration of 20% and a fibrinogen solution with a mass volume concentration of 1%. Equal volumes of the protein solution were mixed to obtain a hydrogel material solution for use.

[0055] (3) Preparation of synthetic polymer solutions: PLGA was dissolved in tetraethylene glycol to obtain solutions with mass volume concentrations of 2% and 15% for use.

[0056] (4) Preparation of cell-containing material: mix adipose stem cells (ADSC), glycerol cryopreservation agent and the above-mentioned hydrogel material solution, and the ADSC concentration of the hydrogel solution is 5×10 6 cells / mL, the volume concentration of glycerol cryopreser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com