Surface carbon coating method of lithium iron phosphate positive electrode material

A technology of lithium iron phosphate and cathode material, applied in battery electrodes, electrical components, circuits, etc., can solve the problems affecting the electrochemical performance of lithium iron phosphate materials, and achieve the effect of excellent rate charge and discharge performance and uniform carbon layer coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1. Weigh lithium carbonate, ferrous oxalate, ammonium dihydrogen phosphate, and sucrose according to the molar ratio Li:Fe:P:C=1.02:1:1:0.05, use alcohol as a dispersant for ball milling and disperse, and then vacuum dry processing to obtain dry matter.

[0021] 2. The dry material obtained in step 1 is sintered under the protection of nitrogen, firstly kept at 500°C for 5h, and then at 700°C for 10h, the heating rate during the whole process is 5°C / min. The pulverized sintered material can be obtained after cooling naturally.

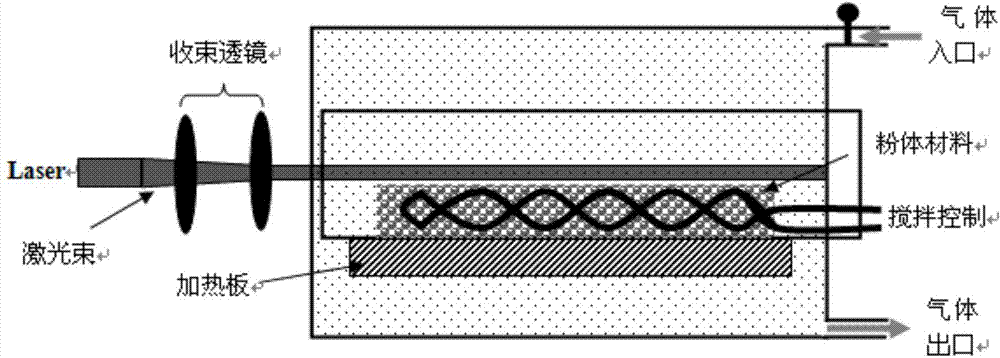

[0022] 3. The sintered material obtained in step 2 is placed in a laser chemical vapor deposition reaction device for vapor-phase deposition carbon coating treatment, and a carbon-coated lithium iron phosphate material can be obtained. The specific coating parameters are: the coating temperature is 400°C, the vapor deposition time is 5 hours, the atmosphere condition is a mixed gas of methane gas and nitrogen gas, the volume percentage of metha...

Embodiment 2

[0024] 1. According to the molar ratio Li:Fe:P:C=1.02:1:1:0.12, weigh lithium hydroxide, ferrous oxalate, ammonium dihydrogen phosphate, and phenolic resin, and use alcohol as a dispersant for ball milling dispersion treatment, and then carry out Vacuum drying treatment to obtain dry material.

[0025] 2. The dried material obtained in step 1 is sintered under the protection of argon, firstly kept at 500°C for 5h, then at 730°C for 10h, and the heating rate during the whole process is 5°C / min. The pulverized sintered material can be obtained after cooling naturally.

[0026] 3. The sintered material obtained in step 2 is placed in a laser chemical vapor deposition reaction device for vapor-phase deposition carbon coating treatment, and a carbon-coated lithium iron phosphate material can be obtained. The specific coating parameters are: the coating temperature is 500°C, the vapor deposition time is 3h, the atmosphere condition is a mixed gas of acetylene gas and argon gas, the...

Embodiment 3

[0028] 1. According to the molar ratio Li:Fe:P:C=1.02:1:1:0.18, weigh lithium acetate, ferrous oxalate, ammonium dihydrogen phosphate, and polyethylene, use acetone as the dispersant for ball milling dispersion treatment, and then vacuum Drying treatment to obtain dry material.

[0029] 2. The dried material obtained in step 1 is sintered under the protection of helium, firstly kept at 500°C for 5h, then at 750°C for 10h, and the heating rate during the whole process is 5°C / min. The pulverized sintered material can be obtained after cooling naturally.

[0030] 3. The sintered material obtained in step 2 is placed in a laser chemical vapor deposition reaction device for vapor-phase deposition carbon coating treatment, and a carbon-coated lithium iron phosphate material can be obtained. The specific coating parameters are: the coating temperature is 600°C, the vapor deposition time is 1h, the atmosphere condition is a mixed gas of acetylene gas and helium gas, the volume percen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com