Microalga photosynthetic aerobic high-density fermentation culture method utilizing inorganic nitrogen source and application

A high-density fermentation, inorganic nitrogen source technology, applied in microorganism-based methods, fermentation, separation methods, etc., can solve the problems affecting the microalgae inorganic nitrogen assimilation process, affecting the effect of industrial flue gas emission reduction, slow cell growth rate, etc. problems, to achieve the effect of stable and controllable cultivation process, convenient operation and easy method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

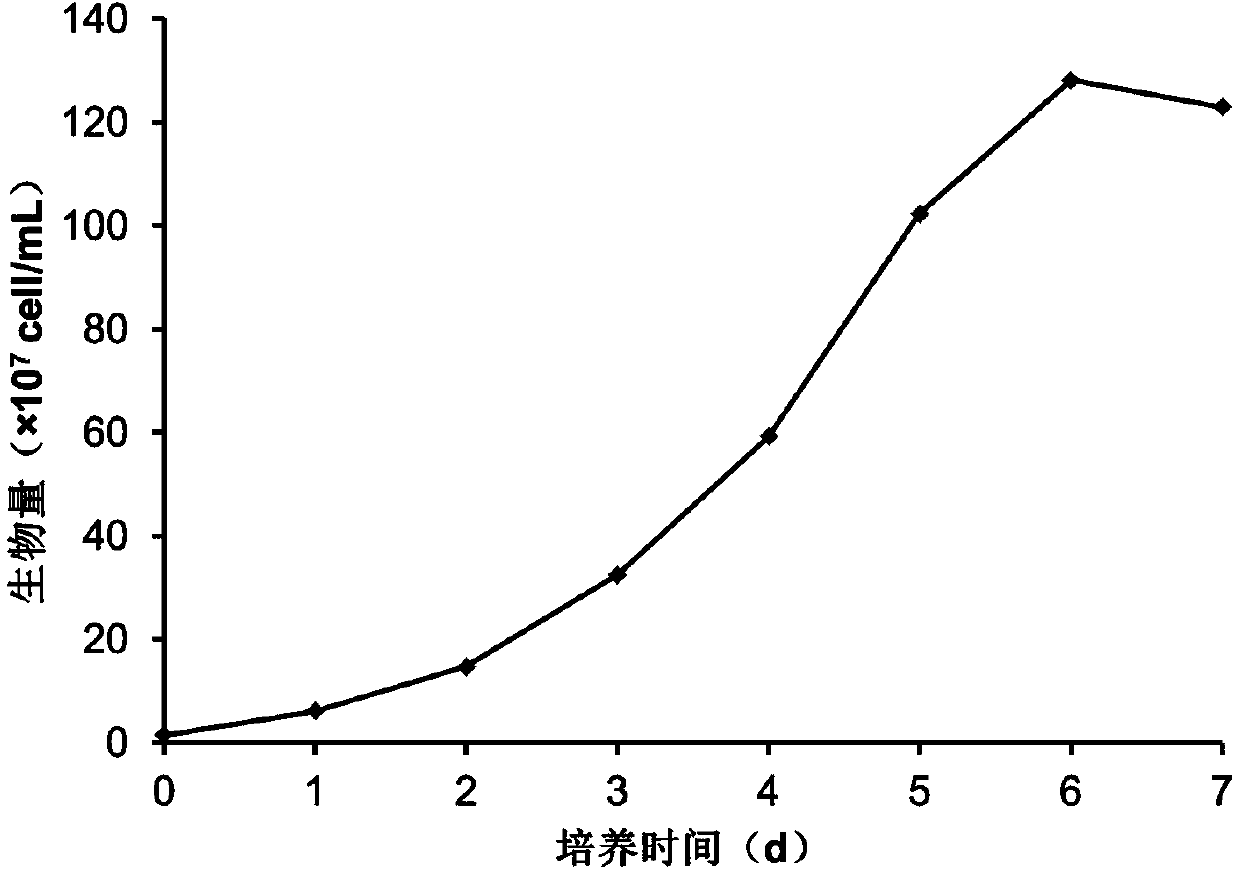

Embodiment 1

[0048] Prepare medium

[0049] The preparation process of basal medium is as follows:

[0050] Add glucose and NaNO to BG11 medium 3 Prepare basal medium so that the concentration of glucose in the medium is 30g / L, NaNO 3 The content is 4.5g / L;

[0051] The composition of BG11 medium is: NaNO 3 1.5g / L, K 2 HPO 4 ·3H 2 O0.04g / L, MgSO 4 ·7H 2 O0.075g / L, CaCl 2 2H 2 O0.036g / L, citric acid, 0.006g / L, ferric ammonium citrate 0.006g / L, EDTA 2Na, 0.001g / L, Na 2 CO 3 0.02g / L, A 5 Solution 1mL / L; trace element solution A 5 The composition is: H 3 BO 3 2.86g / L, MnCl 2 4H 2 O1.81g / L, ZnSO 4 ·7H 2 O0.222g / L, Na 2 MoO 4 2H 2 O0.390g / L, CuSO 4 ·5H 2 O0.079g / L, CoCl 2 ·6H 2 O0.010g / L.

[0052] The preparation process of feed solution is as follows:

[0053] Add glucose to deionized water so that its concentration is 800g / L to prepare feeding solution 1;

[0054] Add NaNO to deionized water 3 Make its concentration 150g / L to prepare feeding solution 2;

[0055] ...

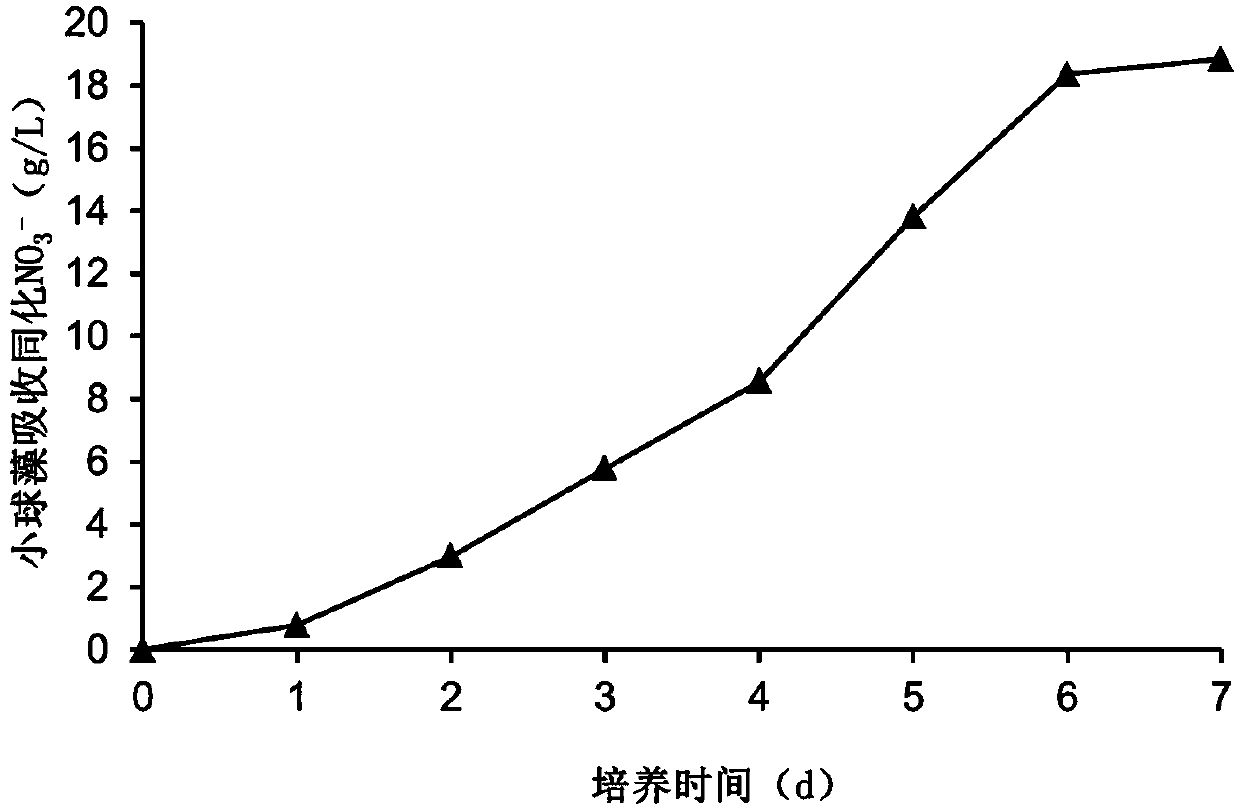

Embodiment 2

[0060] A microalgae photosynthetic and adjunct culture high-density fermentation culture method using inorganic nitrogen source, taking 3L culture scale as an example, the details are as follows:

[0061] 1. Use a 5L self-controlled light bioreactor (Shanghai Baoxing Biological Equipment Engineering Co., Ltd., BIOTECH-5BGG) for photosynthetic and high-density fermentation of Chlorella, with a culture volume of 3L basal medium. Turn on the photobioreactor and set the culture conditions to an average light intensity of 200 μmol m -2 the s -1 , the temperature is 28°C, compressed air (0.08MPa) is used for ventilation, the ventilation rate is 3.0L / min (that is, the ventilation rate per liter of medium is 1L / min), the stirring speed is 200rpm, and 2M KOH solution and 70% The acetic acid solution automatically adjusts the pH of the culture solution to make the pH 7.0.

[0062] 2. Microalgae inoculation and cultivation. After the culture conditions in the photobioreactor are stabl...

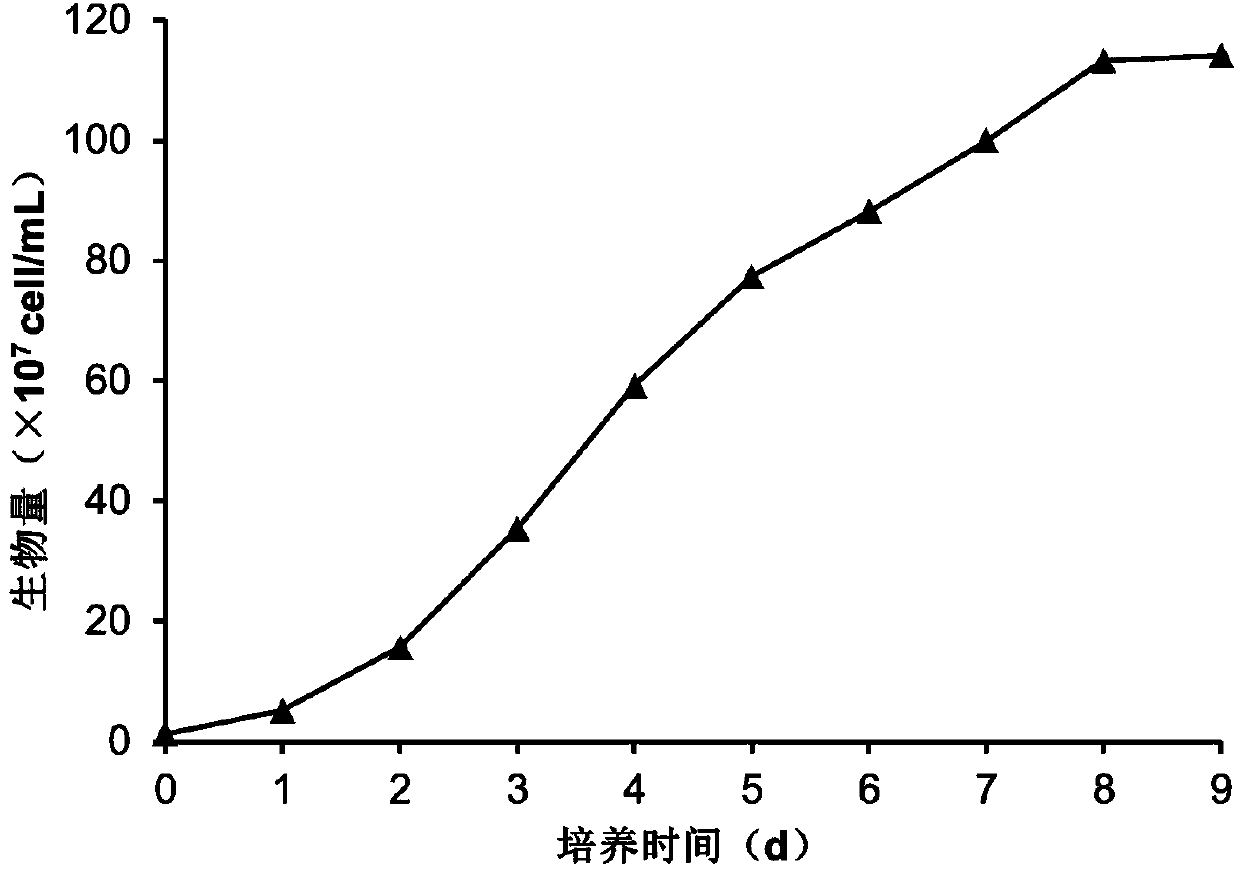

Embodiment 3

[0066] A method for microalgae photosynthetic and trophic high-density fermentation using an inorganic nitrogen source, taking a 30L culture scale as an example, the details are as follows:

[0067] 1. Use a 50L self-controlled light bioreactor (Shanghai Baoxing Biological Equipment Engineering Co., Ltd., BIOTECH-50BSG) for photosynthetic and high-density fermentation of Chlorella, with a culture volume of 30L basal medium. Turn on the photobioreactor and set the culture conditions to an average light intensity of 300 μmol m -2 the s -1 , the temperature is 28°C, compressed air (0.08MPa) is used for ventilation, the ventilation rate is 45.0L / min (that is, the ventilation rate per liter of medium is 1.5L / min), the stirring speed is 200rpm, and 2M KOH solution and 70 % acetic acid solution automatically adjusts the pH value of the culture medium to make the pH 7.0.

[0068] 2. Microalgae inoculation and cultivation. After the culture conditions in the photobioreactor were sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com