Electrolyte for lithium battery and lithium battery using the same

A lithium battery and electrolyte technology, applied in primary batteries, lithium storage batteries, secondary batteries, etc., can solve problems such as excessive growth, high self-discharge rate, and battery passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

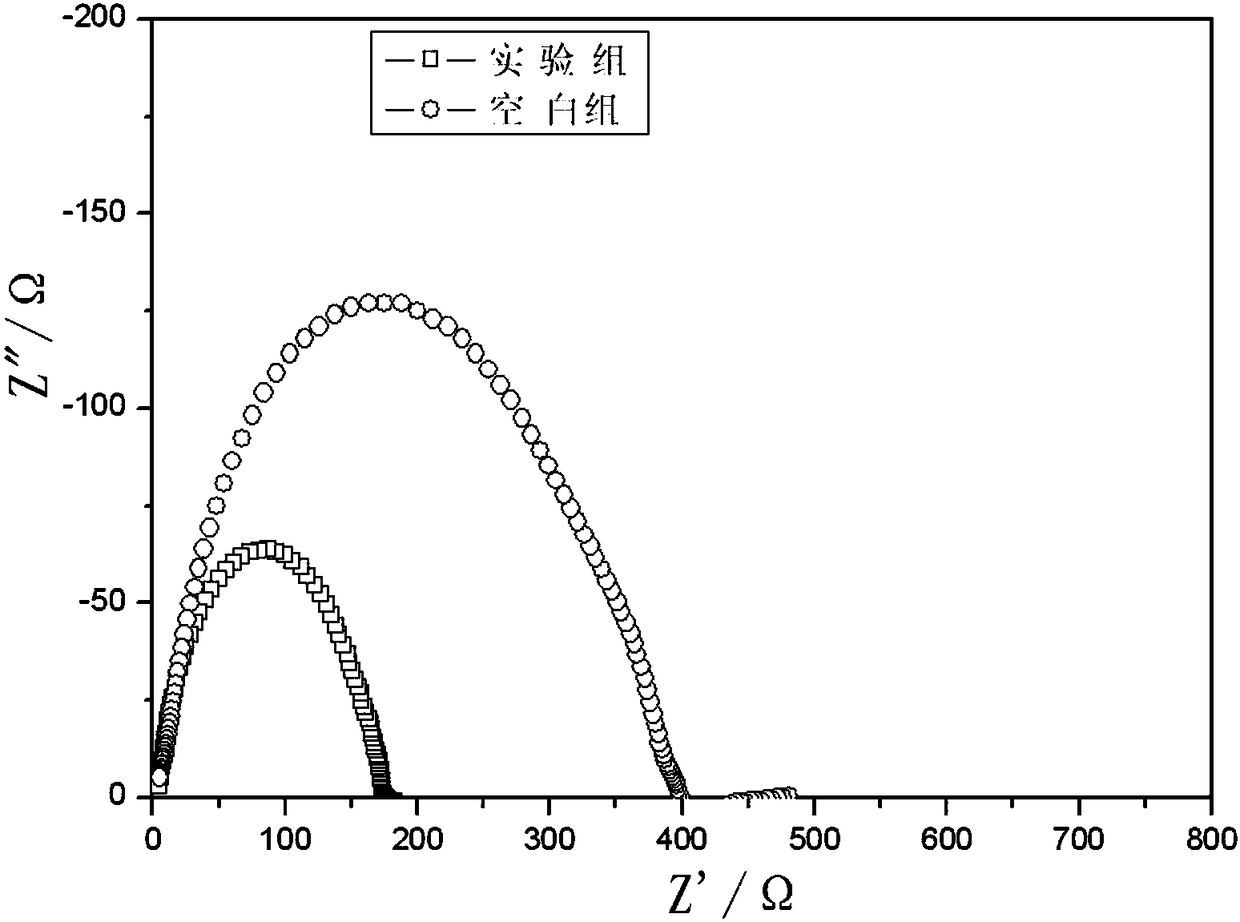

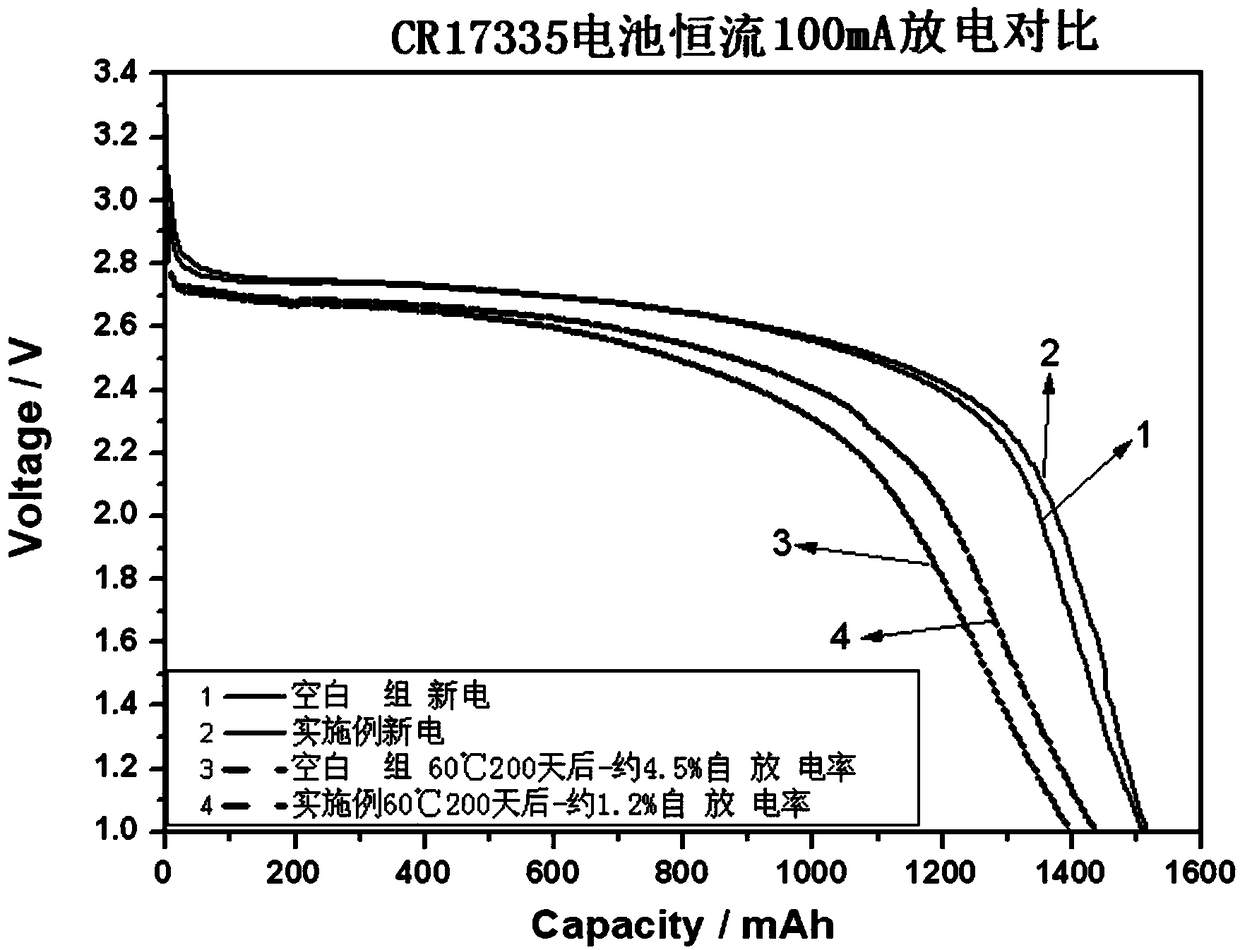

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] An embodiment of the electrolyte solution for lithium batteries of the present invention, the electrolyte solution described in this embodiment is used for lithium / thionyl chloride batteries, the electrolyte solution contains a conventional electrolyte solution and a pyridine ionic liquid, and the pyridine ionic liquid contains Cation and anion, the cation is N-butylpyridine, the anion is aluminum tetrachloride ion, and the conventional electrolyte is LiAlCl with a concentration of 1.5M 4 -SOCl 2 Lithium / thionyl chloride conventional electrolyte, the volume percentage of pyridine ionic liquid in the electrolyte is 1%. The electrolyte solution of this embodiment is prepared by the following method:

[0032] (1) Pre-electrolysis: Use high-purity aluminum sheets for the positive and negative electrodes in an anhydrous environment, connect to a regulated power supply with a voltage of 1.08V, and perform electrolysis for 24 hours to remove the moisture in the pyridine-based...

Embodiment 2

[0035] An embodiment of the electrolyte solution for lithium batteries of the present invention, the electrolyte solution described in this embodiment is used for lithium / thionyl chloride batteries, the electrolyte solution contains a conventional electrolyte solution and a pyridine ionic liquid, and the pyridine ionic liquid contains Cation and anion, the cation is N-n-butylpyridine, the anion is tetrachlorogallate ion, and the conventional electrolyte is LiAlCl with a concentration of 1.5M 4 -SOCl 2 Lithium / thionyl chloride conventional electrolyte, the volume percentage of pyridine ionic liquid in the electrolyte is 5%. The preparation method of the electrolyte solution of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0037] An embodiment of the electrolyte solution for lithium batteries of the present invention, the electrolyte solution described in this embodiment is used for lithium / thionyl chloride batteries, the electrolyte solution contains a conventional electrolyte solution and a pyridine ionic liquid, and the pyridine ionic liquid contains Cation and anion, the cation is N-picoline, the anion is bis(trifluoromethylsulfonyl)imide anion, and the conventional electrolyte is LiAlCl with a concentration of 1.5M 4 -SOCl 2 Lithium / thionyl chloride conventional electrolyte, the volume percentage of pyridine ionic liquid in the electrolyte is 10%. The preparation method of the electrolyte solution of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com