Growth method of micro-nano functional material and application thereof in quantum dot cell

A technology of functional materials and growth methods, applied in the field of micro-nano functional material growth methods and quantum dot battery applications, to achieve the effects of easy industrialization, low cost, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: A multifunctional device for growing nanomaterials based on hydrothermal method

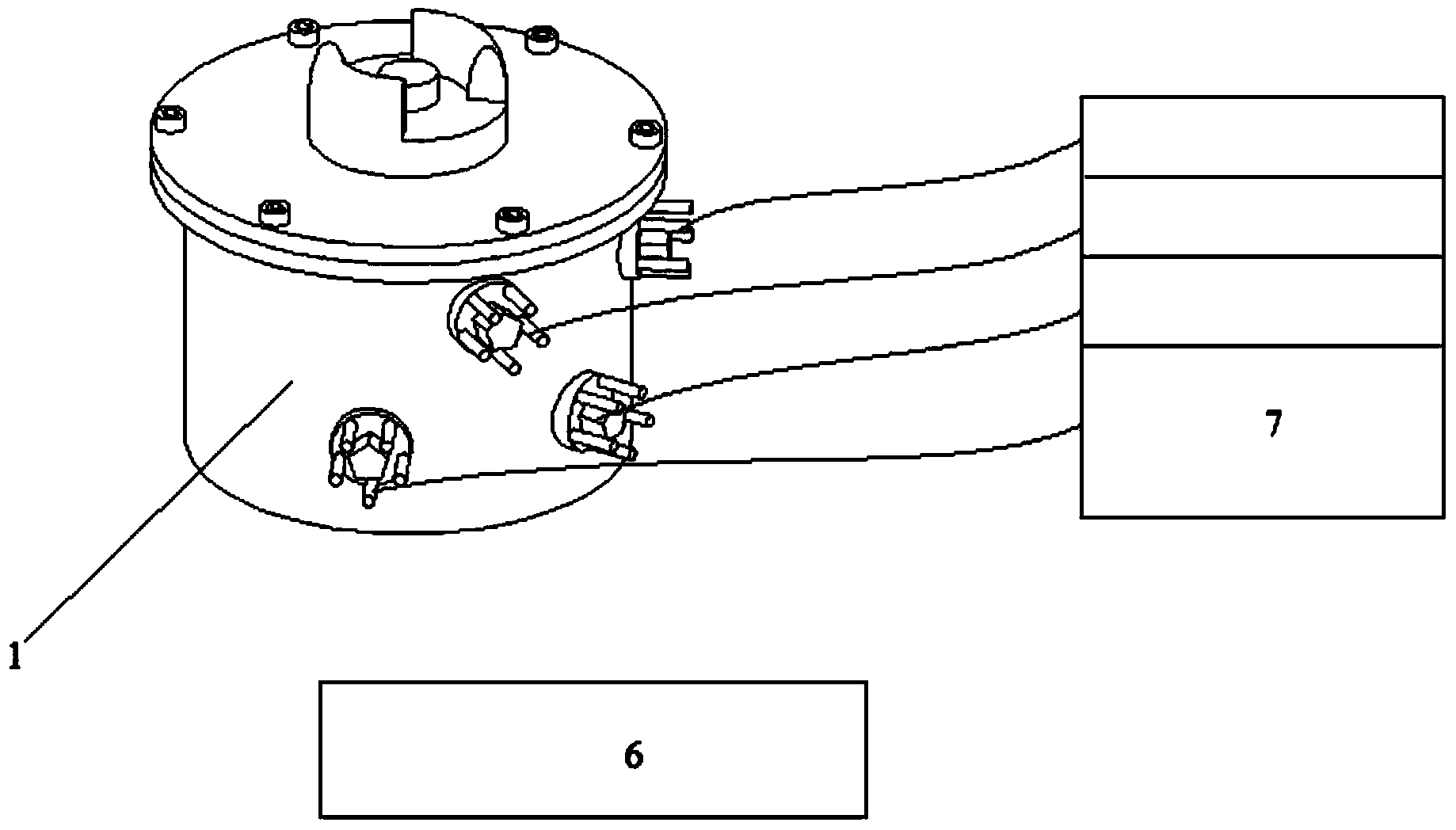

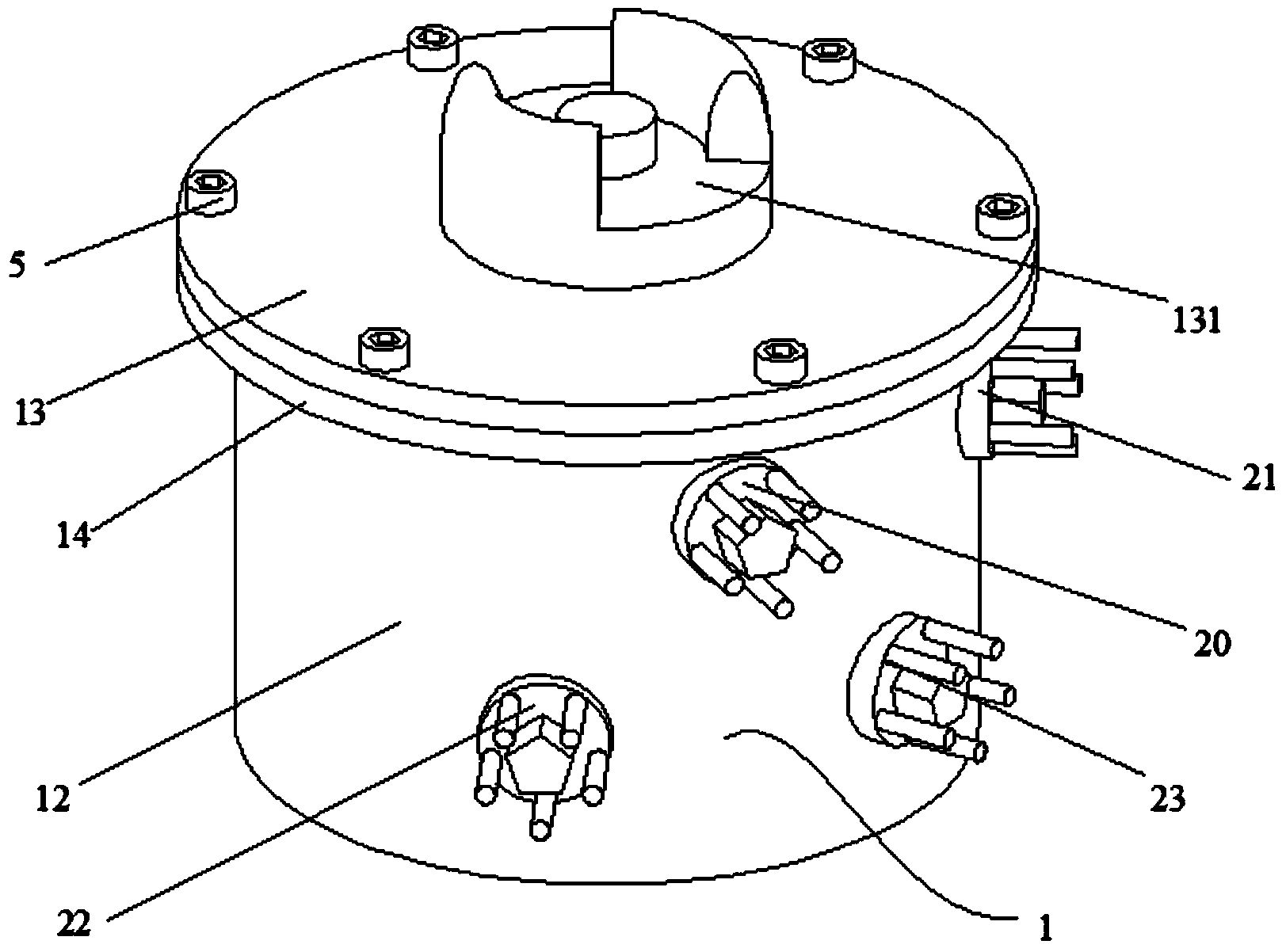

[0046] Such as Figure 1~2 Shown, a kind of multifunctional device based on hydrothermal growth nanometer material, this container comprises airtight container 1, heating device 6 and signal display device 7,

[0047] Described airtight container is made up of container bottom, container wall 12 and container cover 13;

[0048] The container wall 12 is integrally formed with the bottom of the container. In the present embodiment, the container is a cylindrical container, such as being designed with an outer diameter of 45 cm, a thickness of the container wall of 2 cm, and a height of 32 cm. These parameters can be adjusted according to production needs. re-customization;

[0049] The container cover 13 is screwed to the container wall 12. Specifically, in this embodiment, the top end of the container wall 12 is provided with a mounting flange 14, and the flange surface is provid...

Embodiment 2

[0053] Example 2: Growth of Rosette Zinc Oxide on Silicon Substrate

[0054] (1) Clean the silicon substrate. Clean according to standard RCA procedures.

[0055] (2) Prepare 3nm zinc oxide seed crystals by magnetron sputtering method, the sputtering parameters are Ar flow rate 5-14.1sccm; working pressure 3Pa; plate flow 160mA; forward power 100w; self-bias voltage 0.18kV; standing wave ratio 0.55 -3.

[0056] (3) Put the growth substrate into a muffle furnace and anneal at 650°C for 0.5h.

[0057] (4) Prepare the nutrient solution used for growing nanomaterials. Prepare a mixed solution of dehydrated zinc acetate (0.1mol / L) and hexamethylenetetramine (0.01mol / L).

[0058] (5) The growth substrate with the seed layer was vertically fixed on the sample holder and placed into a self-designed multifunctional hydrothermal growth device (see Example 1).

[0059] (6) Pour the nutrient solution prepared in step (4) (be careful not to exceed the liquid phase area), and seal the ...

Embodiment 3

[0064] Example 3: Growth of rosette zinc oxide on FTO substrate

[0065] (1) Clean the conductive glass substrate. Ultrasonic cleaning with acetone for 10s, then ultrasonic cleaning with absolute ethanol for 10s, then deionized water for 10s, and finally drying the substrate with nitrogen;

[0066] (2) 4nm zinc oxide seed crystals were prepared by magnetron sputtering, the sputtering parameters were Ar flow rate 5-14.1sccm; working pressure 3Pa; plate flow 160mA; forward power 100w; self-bias voltage 0.18kV; standing wave ratio 0.55 -3.

[0067] (3) Put the growth substrate into a muffle furnace and anneal at 350°C for 0.5-3h.

[0068] (4) Prepare the nutrient solution used for growing nanomaterials. Prepare a mixed solution of dehydrated zinc acetate (0.1mol / L) and hexamethylenetetramine (0.01mol / L).

[0069] (5) After fixing the growth substrate with the seed layer on the sample holder, put it vertically into a self-designed multifunctional hydrothermal growth device (se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com