Extraction method for benzo(a)pyrene in edible oil

An extraction method and edible oil technology, which is applied in the field of food analysis, can solve problems such as unclear retention time, unfavorable absorption and separation, and great influence on the results, so as to reduce the steps of column packing and activation, simple and fast operation steps, good sensitivity and The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

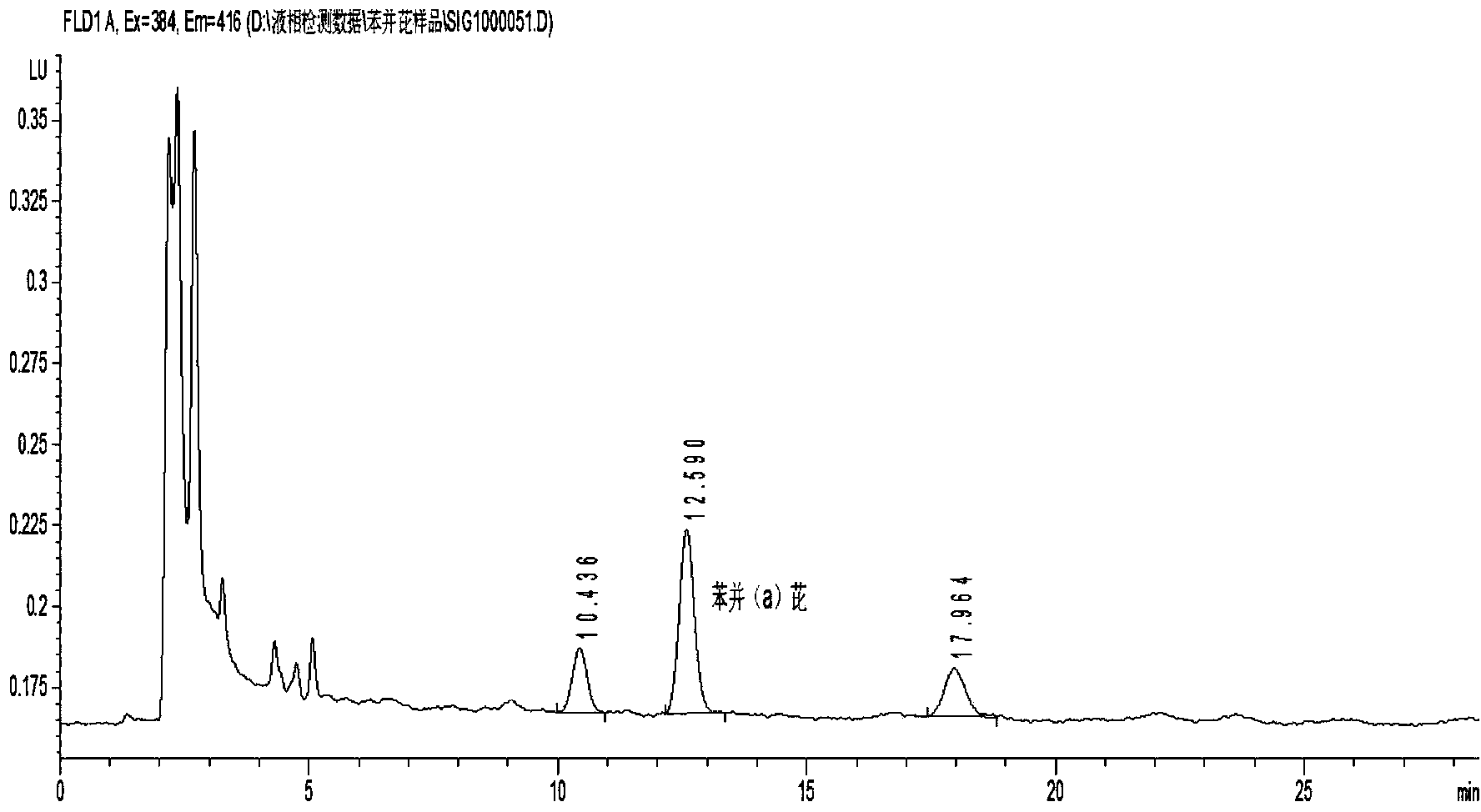

[0043] Accurately weigh 0.5g of primary-pressed peanut oil (accurate to 0.001g) into a 15mL screw-cap plastic centrifuge tube, add 4mL of acetonitrile saturated with n-hexane, vortex for 5min, centrifuge at -18°C at 3500rpm for 15min, and separate the acetonitrile layer Transfer to another clean plastic tube. The extraction was repeated twice, and the acetonitrile layers were combined to obtain the extract.

[0044] Add 0.2g of solid adsorbent SAX to the extract (10ml), vortex for 2min, 3000rpm, centrifuge for 5min, remove the upper purified solution and blow it to dryness with nitrogen at 40°C, add 1mL of acetonitrile to redissolve, and pass through a 0.45μm organic filter membrane , for liquid phase detection, the conditions of liquid phase detection are: analytical chromatographic column: polycyclic aromatic hydrocarbon analysis column, column length 250mm, inner diameter 4.6mm, particle diameter 5μm; column temperature: 40 ℃; detector: FLD fluorescence detector, excitation...

Embodiment 2

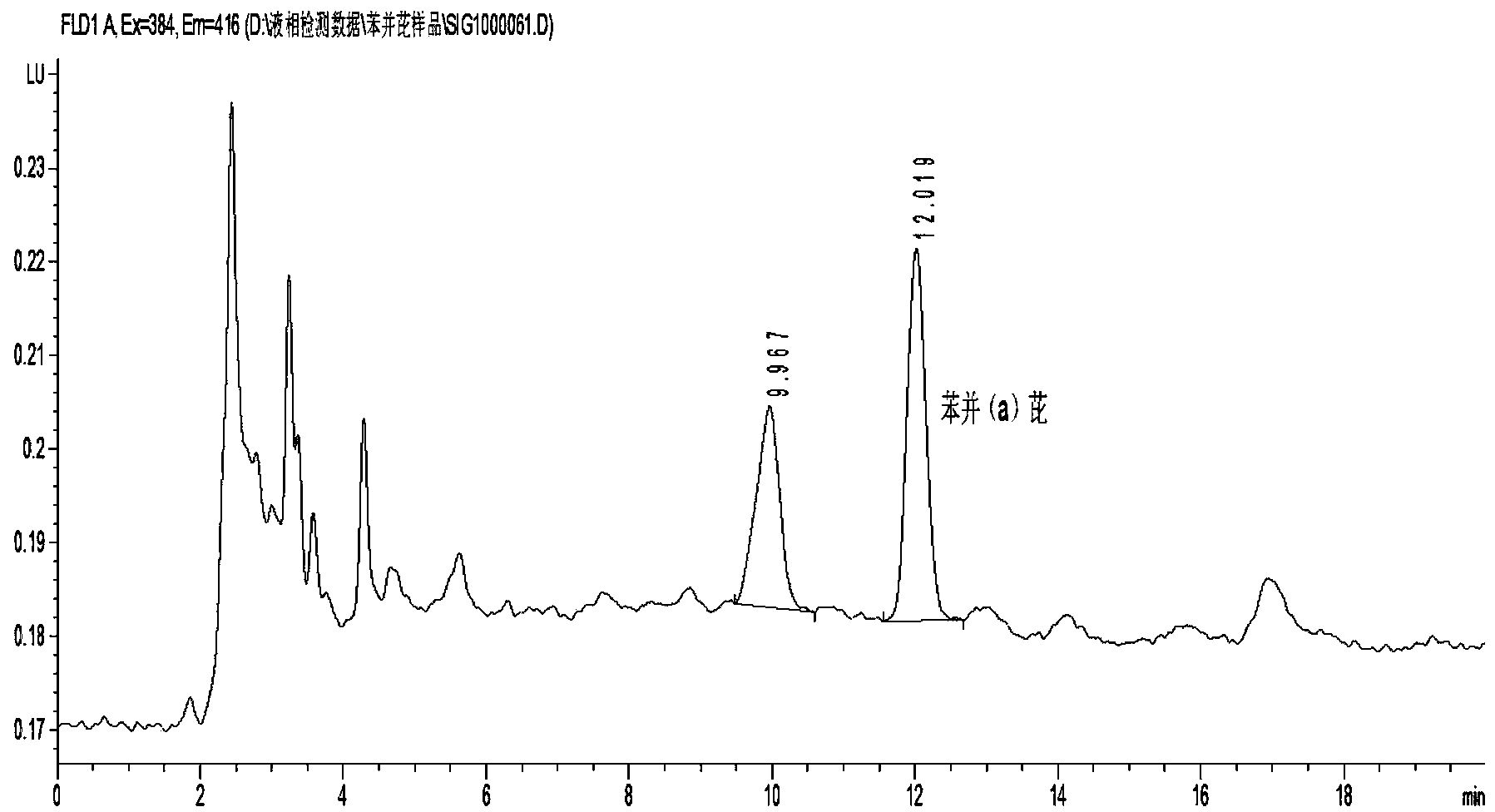

[0046] Accurately weigh 0.5g of first-grade corn oil (accurate to 0.001g) into a 15mL screw-cap plastic centrifuge tube, add 5mL of acetonitrile saturated with n-hexane, vortex for 2min, centrifuge at -22°C at 4000rpm for 10min, and separate the acetonitrile layer Transfer to another clean plastic tube. The extraction was repeated 3 times, and the acetonitrile layers extracted three times were combined to obtain the extract.

[0047] Add 0.3g of solid adsorbent SAX to the extract (10ml), vortex for 2min, 3000rpm, centrifuge for 3min, remove the upper purified solution and blow it to dryness with nitrogen at 45°C, add 1mL of acetonitrile to redissolve, pass through a 0.45μm organic filter membrane , for liquid phase detection, the conditions for liquid phase detection are: analytical chromatographic column: polycyclic aromatic hydrocarbon analysis column, column length 250mm, inner diameter 4.6mm, particle size 5μm; column temperature: 40°C; detector: FLD fluorescence detector,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com