Cell stent with carbon nano tube and preparation method thereof

A cell scaffold and carbon nanotube technology, applied in the field of tissue engineering, can solve the problems of single uncontrollable mechanical properties, unsatisfactory, limited application scope of pure PLGA bioscaffold materials, etc., and achieve excellent mechanical properties, biological properties, and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] 1. Preparation of samples to be tested: PLGA15% (W / V) + CTNs0.2% (W / V)

[0034] The preparation stage of the electrospinning solution, that is, using HFIP with a wide dissolution spectrum as the solvent system for carrying different polymers to co-exist, and preparing PLGA and CNTs into hexafluoroethylene propanol polymer solutions and suspensions respectively, Then combine the two, magnetic stirring and mixing to obtain a spinning solution with uniform composition.

[0035] 1. First, weigh 1.05g of PLGA solid particles as the main body of electrospinning polymers and dissolve them in 3ml HFIP (half-volume total solvent volume), heat in a water bath (37°C) for 4-5 hours until completely dissolved, and obtain PLGA Solution, that is, PLGA polymer spinning liquid matrix.

[0036] 2. Then add 0.014g of CNTs into 4ml HFIP (half-volume total solvent volume) for ultrasonic treatment for 2 hours to form a uniformly dispersed CNTs suspension. After stirring with a magnetic sti...

Embodiment 2

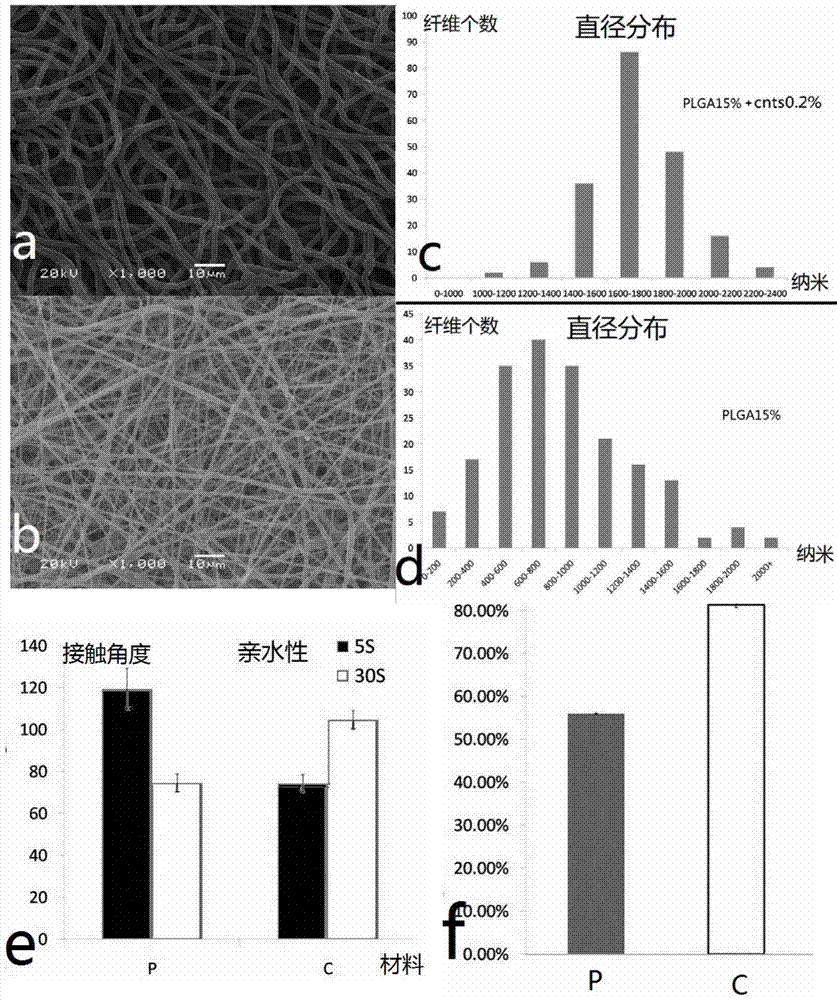

[0042] Embodiment 2 Surface morphology and diameter distribution

[0043] Cut the sample materials of the test group and the control group: PLGA15% (W / V) + CTNs0.2% (W / V) and the simple component PLGA15% (W / V) to cut out 1cm×1cm square samples, spray gold half Hours, the microscopic morphology was examined under a scanning electron microscope. After spraying gold and irradiating the scanning electron microscope, select three 1000× magnified field of view photos for each material, so that the field of view should reflect the fiber microscopic distribution of the selected material as representatively as possible. Six fields of view were randomly selected from each scanning electron microscope photo, and 5 fibers were randomly selected in each field of view to measure the diameter. A total of 90 fibers were selected for each concentration of CNTs material, and the diameters of these fibers were measured and analyzed using imageJ software.

[0044] Results and analysis: The above...

Embodiment 3

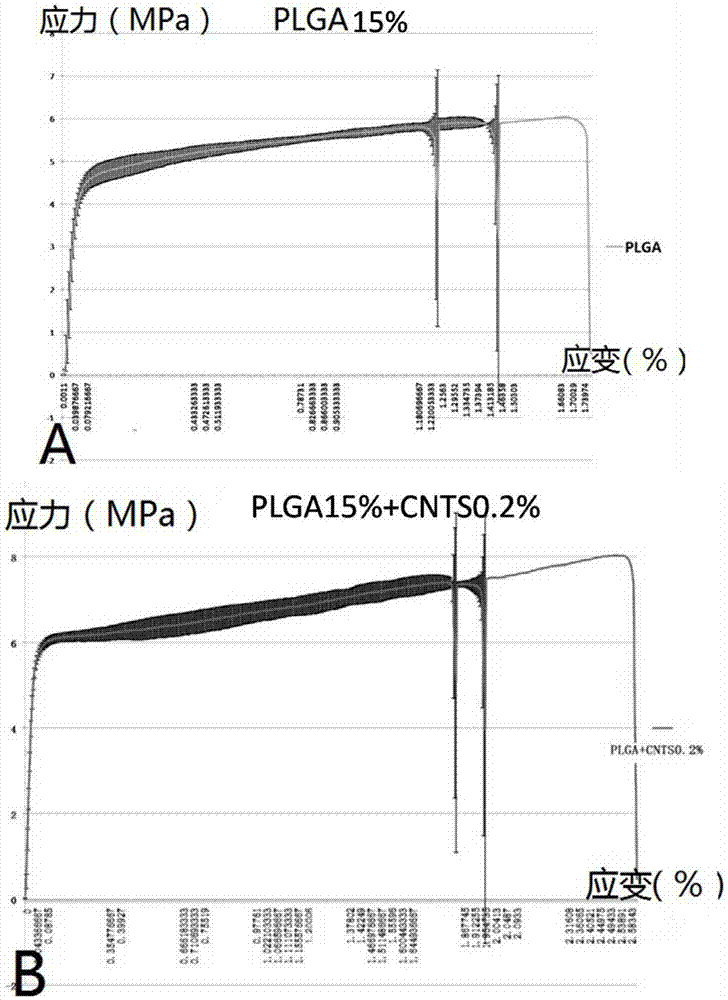

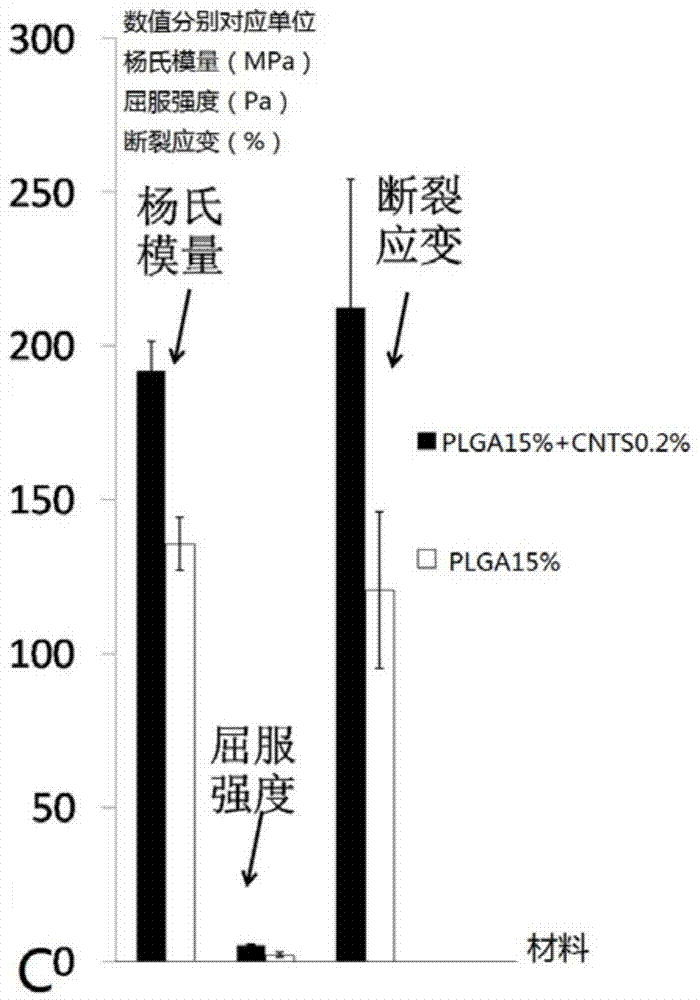

[0045] Embodiment 3 mechanical performance detection

[0046] The Young's modulus, yield strength, and fracture strain of the material were obtained through the tensile failure test of the INSTRON5948 mechanical tensile tester. All material samples have been pretreated as follows before the tensile test: the sample materials of the test group and the control group: PLGA15% (W / V) + CTNs0.2% (W / V) and simple component PLGA15% (W / V) were cut into 5cm×1cm dumbbell-shaped structures, and the thickness of each material was measured with a spiral micrometer. A 1cm×1cm square clamping position is reserved at each end, and the working area is 3cm×1cm, and 5 groups of parallel experiments are done for each material.

[0047] Tensile failure test: Clamp both ends of the material strip on the hydraulic clamp, and pull the material axially at both ends at a constant speed of 10mm / min after fixing until the material breaks. The stress-strain curve of each material is obtained, and the Yo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com