Method for continuously and quickly measuring copper and iron in ore leaching solution

A technology for rapid determination and leachate, which is applied in the direction of chemical analysis by titration method and analysis by chemical indicators, etc. It can solve the problems that it is not suitable for rapid analysis of large quantities of ore leachate, the processing time of ore leachate is long, and the operation of the analysis process is cumbersome. Achieve the effects of shortening the analysis and determination time, easy control of the operation process, and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

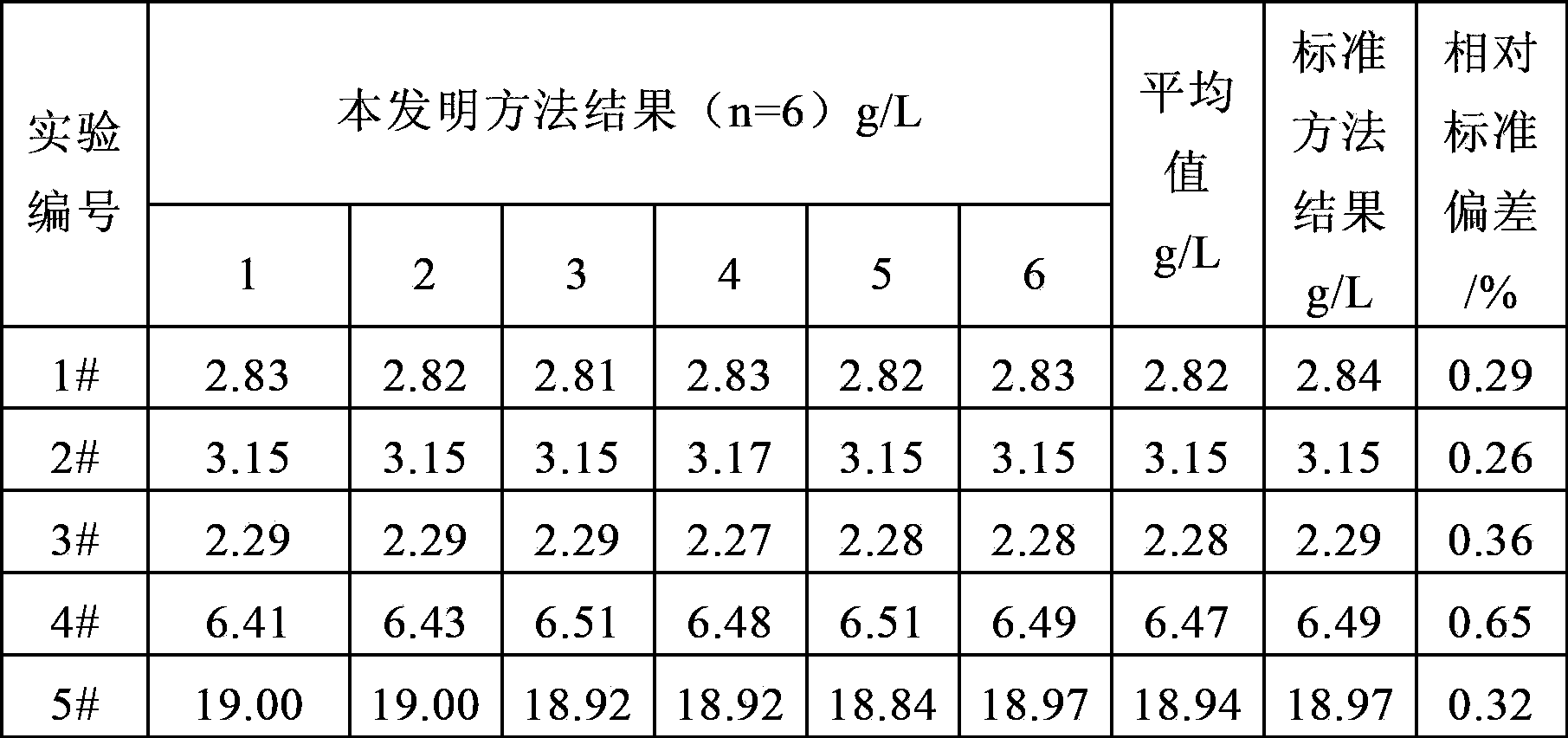

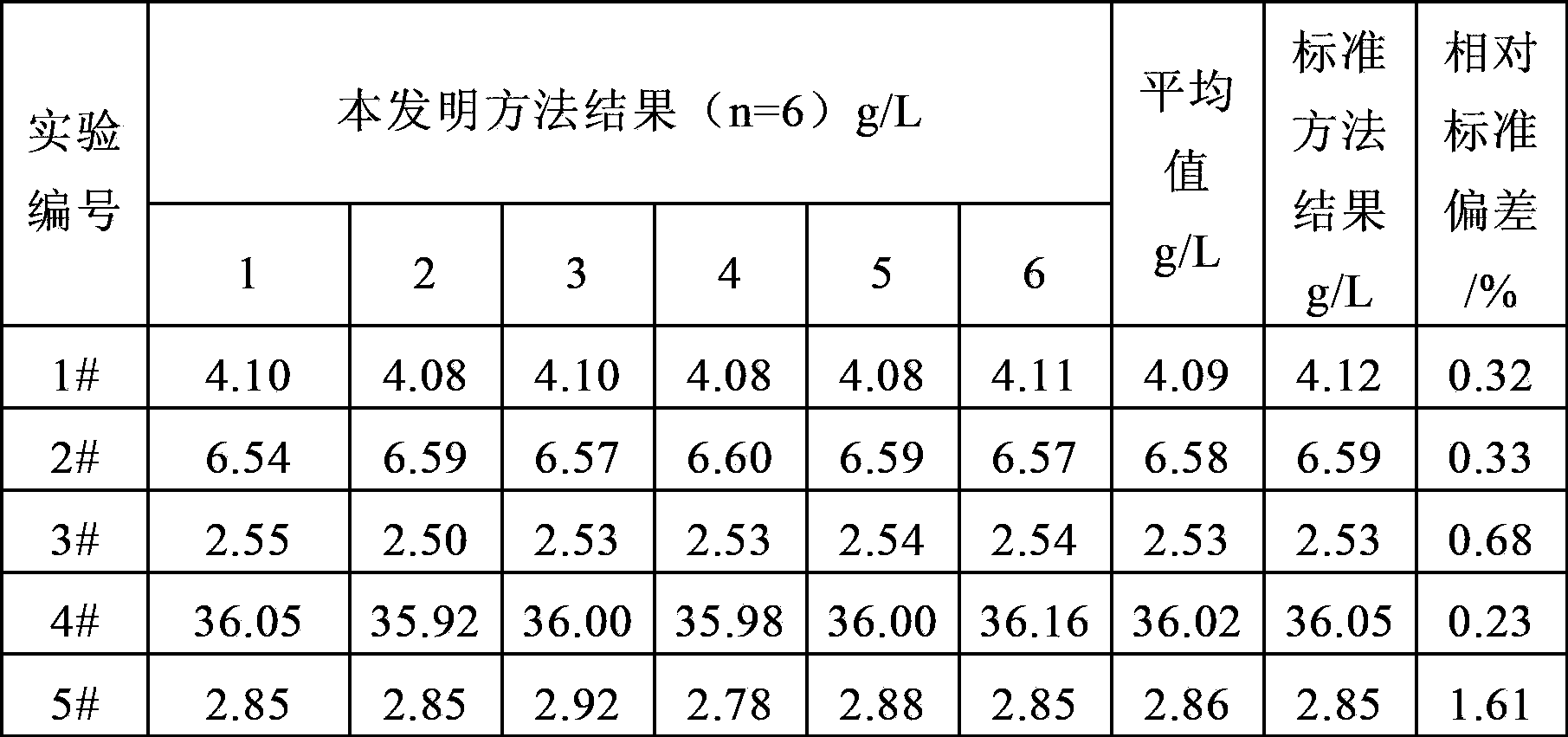

Examples

Embodiment 1

[0025] Pipette 5.00mL of ore leaching solution into a 250mL Erlenmeyer flask, add 2.0mL of hydrogen peroxide, heat the ore leaching solution at low temperature to a volume of 1-2mL, cool to room temperature, and add dropwise acetic acid-ammonium acetate buffer solution with pH ≈ 5 to the solution. The red color no longer deepens and an excess of 2 mL is added dropwise to a saturated solution of ammonium bifluoride until the red color disappears and an excess of 0.5 mL is added. Rinse the wall of the bottle with a small amount of water and shake well. Add 1-2 g of potassium iodide to the solution and shake well. Quickly titrate with sodium thiosulfate standard solution (standard solution titer: fCu=1.5836mg / mL; fFe=1.3917mg / mL) until light yellow. Add 1mL of 5g / L starch solution and continue titrating until the blue just disappears, which is the end point. Consumption of sodium thiosulfate standard solution 7.17mL, copper ion concentration in the solution is 2.27g / L. Add 8.0mL...

Embodiment 2

[0027] Pipette 10.00mL of ore leaching solution into a 100mL volumetric flask, dilute to the mark, shake well, divide 10.00mL of solution into a 250mL Erlenmeyer flask, add 2.0mL of hydrogen peroxide, heat the ore leaching solution at low temperature until the volume is 1-2mL, cool to At room temperature, add acetic acid-ammonium acetate buffer solution with pH ≈ 5 dropwise to the solution until the red color no longer deepens and an excess of 2mL is added, then a saturated solution of ammonium bifluoride is added dropwise until the red color disappears and an excess of 0.5mL is added. Rinse the wall of the bottle with a small amount of water and shake well , add 1~2g of potassium iodide to the solution and shake well. Quickly titrate with sodium thiosulfate standard solution (fCu=1.5836mg / mL; fFe=1.3917mg / mL) until light yellow. Add 1mL of 5g / L starch solution and continue titrating until the blue just disappears, which is the end point. Consumption of sodium thiosulfate sta...

Embodiment 3

[0029] Pipette 10.00mL of ore leaching solution into a 100mL volumetric flask, dilute to the mark, shake well, divide 10.00mL of solution into a 250mL Erlenmeyer flask, add 2.0mL of hydrogen peroxide, heat the ore leaching solution at low temperature until the volume is 1-2mL, cool to At room temperature, add acetic acid-ammonium acetate buffer solution with pH ≈ 5 dropwise to the solution until the red color no longer deepens and an excess of 2mL is added, then a saturated solution of ammonium bifluoride is added dropwise until the red color disappears and an excess of 0.5mL is added. Rinse the wall of the bottle with a small amount of water and shake well , add 1~2g of potassium iodide to the solution and shake well. Quickly titrate with sodium thiosulfate standard solution (fCu=1.5836mg / mL; fFe=1.3917mg / mL) until light yellow. Add 1mL of 5g / L starch solution and continue titrating until the blue just disappears, which is the end point. Consumption of sodium thiosulfate sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com